For a long time, 3D printing has been synonymous with rapid prototyping and concept development. But technical advances in recent years have meant that this technology is starting to compete in the volume production arena as well, especially in applications with high geometric complexity, customization or need for agility. However, it is important to note that it may not always be the best option.

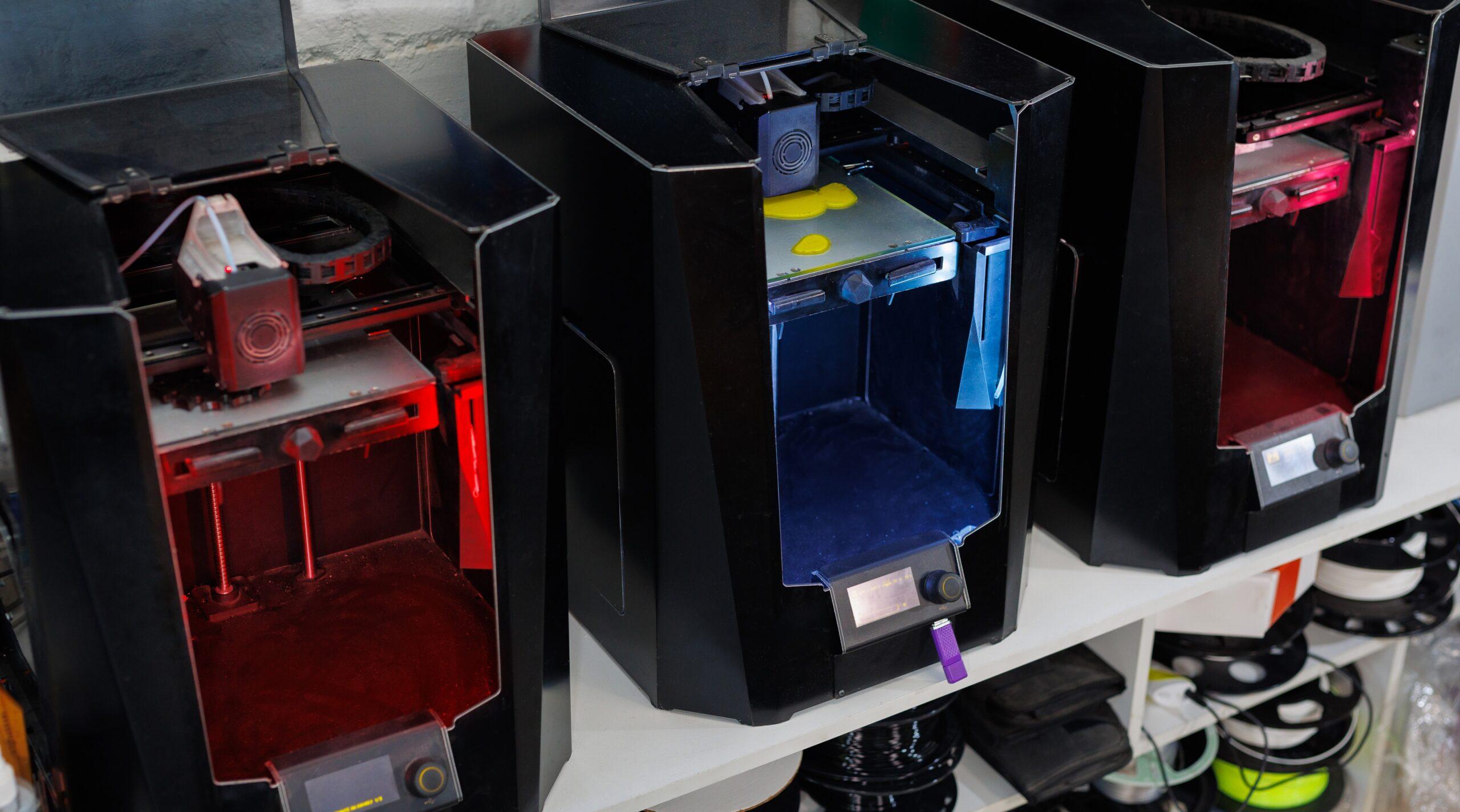

The evolution of additive manufacturing and industrial 3D printers

Thanks to improvements in processes such as SLS (Selective Laser Sintering), MJF (Multi Jet Fusion) or DLP (Digital Light Processing), it is now possible to manufacture thousands of parts with good dimensional accuracy, finish and mechanical properties.

Repeatability, one of the great challenges of additive manufacturing, has improved substantially, enabling functional industrial applications.

When does 3D printing work in production?

3D printing can be very competitive with traditional methods such as injection molding or machining, provided certain conditions are met:

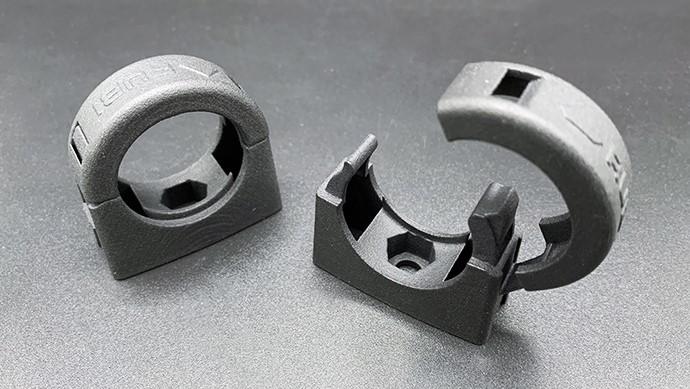

- When the 3D design has complex geometries that are impossible to mold without expensive tooling.

- In projects with massive customization, such as prostheses or products adapted to the user.

- In short or medium series (hundreds or a few thousand units), where manufacturing a mold would be inefficient.

- When seeking to drastically reduce time-to-market, eliminating waiting times for tooling or mold validation.

Current limitations of large-scale 3D printing services

Additive manufacturing still has limitations when it comes to:

- Very long runs: above a certain volume, the cost per unit and production times still favor injection molding.

- Materials with specific requirements, especially thermal or mechanical, that are not available in 3D printing or require complex post-processes.

- Aesthetically demanding finishes: although much improved, the surface finishes of some additive technologies require additional post-processing.

Real applications of 3D printing in different sectors

Hoy en día, la impresión 3D se utiliza con éxito para la producción en serie en diversos sectores industriales. En el campo de los dispositivos médicos, por ejemplo, se producen piezas totalmente personalizadas, como órtesis y prótesis adaptadas a cada paciente. En los sectores automovilístico y aeroespacial, la impresión 3D permite fabricar componentes funcionales con geometrías complejas que serían inviables con métodos tradicionales.

In consumer electronics and wearable devices, housings, supports and internal structures are being manufactured using additive technologies, thus reducing development time and speeding up product launches. It is also used in low-volume but technically demanding industrial products, where design flexibility and the absence of molds provide a key advantage.

These examples show that 3D printing is no longer just about prototyping: it can be a real and competitive solution for mass production, with final quality and tight deadlines.

What can Proto&Go! do for your 3D production?

At Proto&Go! we specialize in HP’s Multi Jet Fusion (MJF) 3D printing technology, designed for industrial applications. This technique allows us to manufacture parts in different materials for 3D printing, such as Polyamide PA12, a rigid and resistant material, or TPA, a robust and flexible material.

Our approach is designed for those looking for agility, design freedom and fast product validation. If you are considering whether 3D printing is viable for your next series, contact us. We can help you analyze the case and choose the most efficient way forward.

Don’t wait any longer and request your quote through our website!