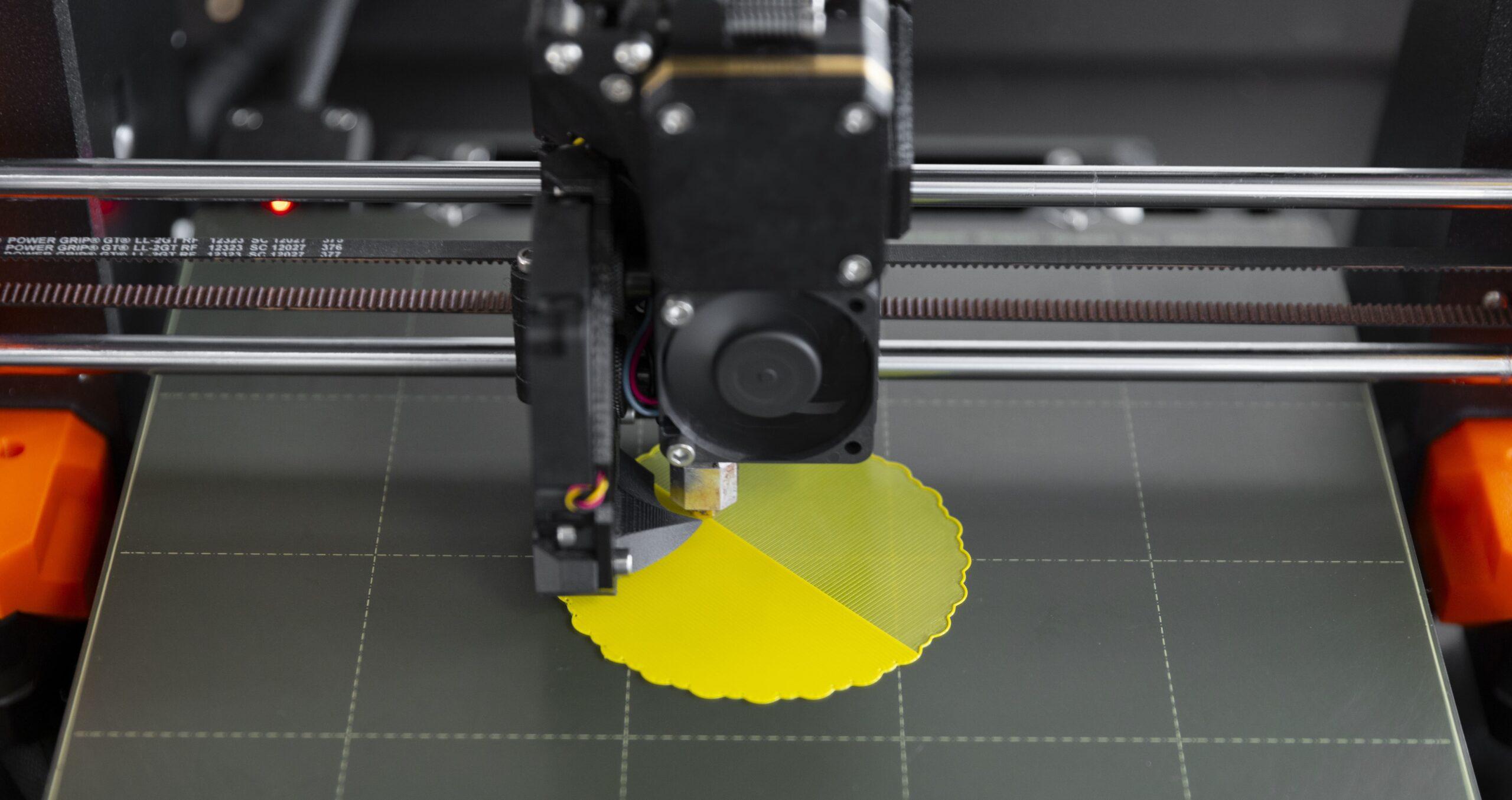

3D printing has revolutionized manufacturing, enabling the creation of complex structures that were previously impossible to achieve with traditional methods. However, one of the most significant challenges in this process is the use of supports.

Supports are temporary structures that are created to hold the parts of a model during printing. Their design and placement can directly affect the quality of the final product, as they can leave marks, cause deformation or require additional time in post-processing.

3D printing companies are developing new strategies to optimize support placement, using advanced algorithms that consider model geometry and material properties. Industrial 3D printing, with technologies such as Multi Jet Fusion (MJF), enables lighter and stronger structures that require less support, reducing material waste and improving the sustainability of the process.

What is hybrid 3D printing and how does it work?

Hybrid 3D printing combines different manufacturing technologies to optimize the production process. Typically, this involves the integration of additive and subtractive methods, such as CNC milling.

This approach not only speeds up production time, but also improves quality, as errors can be corrected at the milling stage.

Additive manufacturing companies are implementing this synergy in multiple industries, from aerospace to medical, where precision and efficiency are crucial. Using HP Multi Jet Fusion 3D printing, as we do at Proto&Go!, accurate, high-quality prototypes can be achieved in less time.

How 3D printing is driving the production of electric vehicles

The automotive industry is undergoing a significant change thanks to 3D printing, especially in the production of electric vehicles.

This technology enables rapid prototyping and the production of customized parts, accelerating the development of new models.

In addition, industrial 3D printing offers the possibility to reduce the weight of components, improving the energy efficiency of EVs. Components such as battery housings and parts of the cooling system can be designed and printed more efficiently.

On the other hand, professional 3D printing companies are experimenting with printing components directly at the production site, which reduces costs and minimizes material waste.

Overall, we can say that additive printing with HP Multi Jet Fusion is transforming the way electric vehicles are produced, making them more accessible and sustainable.

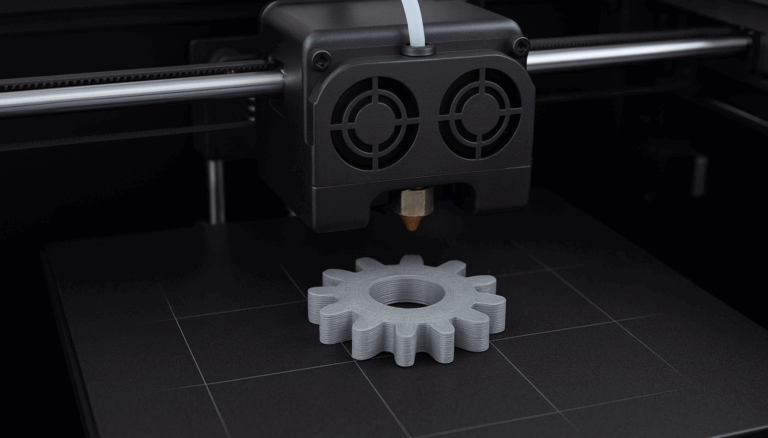

3D printing and robotics: the fusion of two revolutionary technologies

The convergence of 3D printing and robotics is opening new frontiers in manufacturing and design. Robotic systems equipped with 3D printers can create large-scale structures in real time, which is especially useful in construction and industrial component manufacturing. For example, advanced 3D printing with HP Multi Jet Fusion makes it possible to print architectural structures at the construction site, reducing assembly time and logistics costs.

In addition, robots can work collaboratively, using machine learning techniques to improve accuracy and efficiency.

This fusion of technologies is not only transforming the industrial manufacturing landscape, but is also inspiring new applications, such as the creation of customized biomedical tissues. We can therefore say that 3D printing solutions are redefining the boundaries of what is possible in both design and production.

In conclusion, we can say that 3D printing, especially with technologies such as Multi Jet Fusion, is at the center of a technological revolution that spans multiple sectors and disciplines. Its ability to create complex structures, coupled with synergy with robotics and hybrid process innovation, is transforming the way we manufacture and design products today. With the help of leading companies in 3D printing and additive manufacturing services, the future of production is looking more efficient and sustainable.

At Proto&Go! we provide the best service for the development of your parts and prototypes through additive manufacturing. In addition, we specialize in printing using Multi Jet Fusion or MJF, the latest HP technology designed especially for industrial applications.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!