Moving from a functional prototype to mass production is one of the most critical moments in the development of a new product. Making this decision too early can lead to unnecessary investments or manufacturing errors that are difficult to correct. Conversely, delaying this step can allow competitors to get ahead or cause you to miss a market opportunity. So when is the right time to scale up?

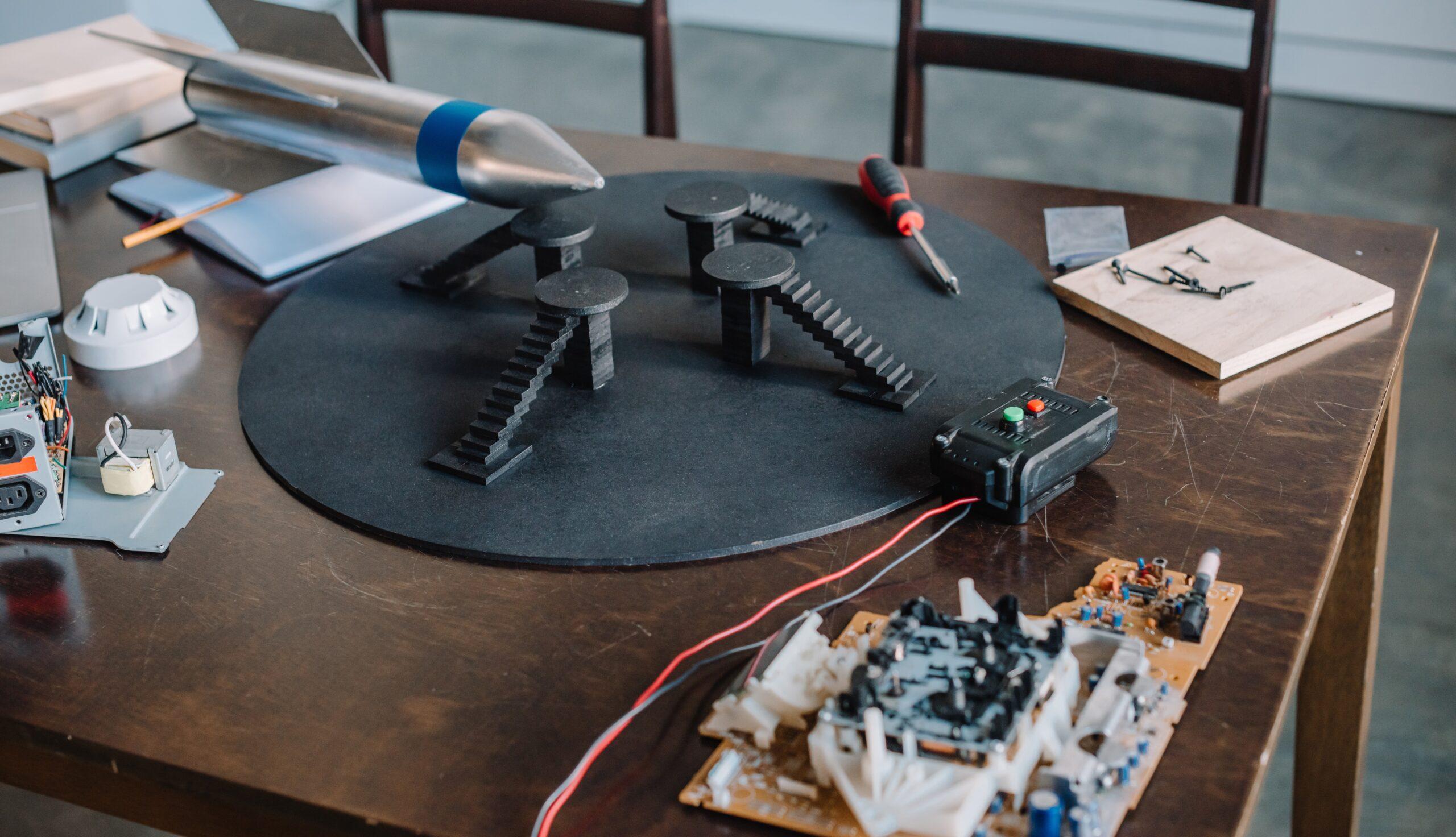

At Proto&Go!, we help startups, engineering firms, and R&D departments to quickly prototype and validate their ideas. But we also know that a product’s success depends not only on its prototype, but also on the strategy used to plan its industrialization.

Functional and usage validation: the first major milestone

Before considering scaling, the prototype must have demonstrated that it fulfills its primary function under real conditions of use. This means not only that it works “in the lab,” but that it behaves reliably, safely, and consistently in the environment in which it will be used.

For example, a medical device must validate its ergonomics, ease of use, and resistance to frequent cleaning. An automotive mechanical component, on the other hand, must pass thermal, vibration, and load cycle tests. In both cases, the prototype is a learning tool, and any weaknesses detected at this stage must be corrected before moving forward.

Design iterations: polish before producing

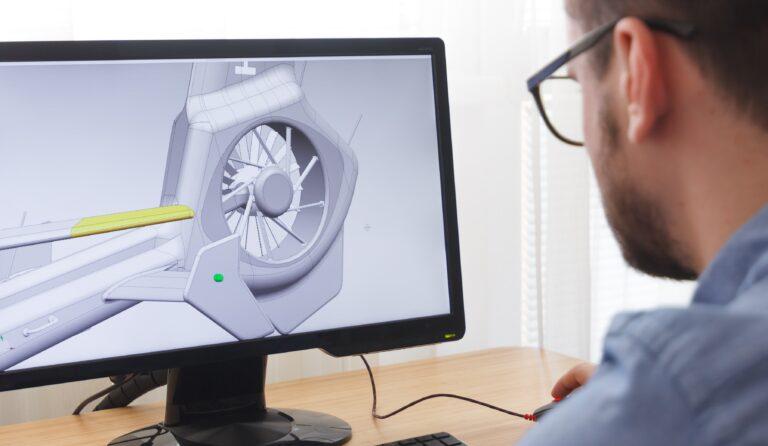

Rapid prototyping allows for agile iteration. Adjusting a geometry, changing a material, or redesigning a joint can be done in a matter of days if you have an agile supplier. These improvements should be incorporated until the design reaches a level of maturity where changes no longer bring significant improvements. At that point, you can start talking about the “final design.”

Technical and economic feasibility of scaling

The next step is to evaluate whether that final design is viable for mass production. Some solutions that work in prototype form may be costly or unfeasible to manufacture on a large scale. That is why it is essential to seek advice on design for manufacturing (DFM). This includes:

- Appropriate selection of materials.

- Choice of manufacturing technology: injection molding, machining, stamping, etc.

- Analysis of tolerances, assemblies, and finishes.

- Estimated costs per unit for different quantities.

What if there is still not enough volume for mass production?

In many cases, the initial market does not yet justify mass production. This is where pre-series and short series play a key role. Manufacturing 50, 100, or 500 units with flexible technologies such as CNC machining or silicone molds allows for:

- Go to market and get real feedback.

- Validate logistics, packaging, and distribution channels.

- Start selling without taking big risks.

This phased approach reduces uncertainty and allows for adjustments to the product or business model before a larger investment is made.

Signs that indicate you are ready to scale

- The prototype has passed all functional tests.

- At least one complete redesign iteration has been completed.

- The unit cost is within the expected profit margin.

- There is real demand, as measured by pre-sales, pilot programs, or distributor interest.

- Production processes are defined and validated on a small scale.

The leap from prototype to production must be a measured process, based on data and validation. Scaling up is not just about producing more, it’s about doing it better, with safety, quality, and efficiency.

Proto&Go!: your partner for moving from prototype to production

At Proto&Go!, we understand that every customer needs speed, clarity, and technical confidence. Our online prototyping platform allows you to easily upload your 3D files, select from technologies such as 3D printing, CNC machining, or silicone molding, and receive a quote in less than 24 hours.

In addition, we offer expert advice at every stage, so you can choose the best material, avoid common mistakes, and receive your prototype ready to move forward with your project. Whether you are a startup, a freelance designer, or a technology center, at Proto&Go! we help you take the next step with confidence.

Upload your 3D file now and request a quote from our website!