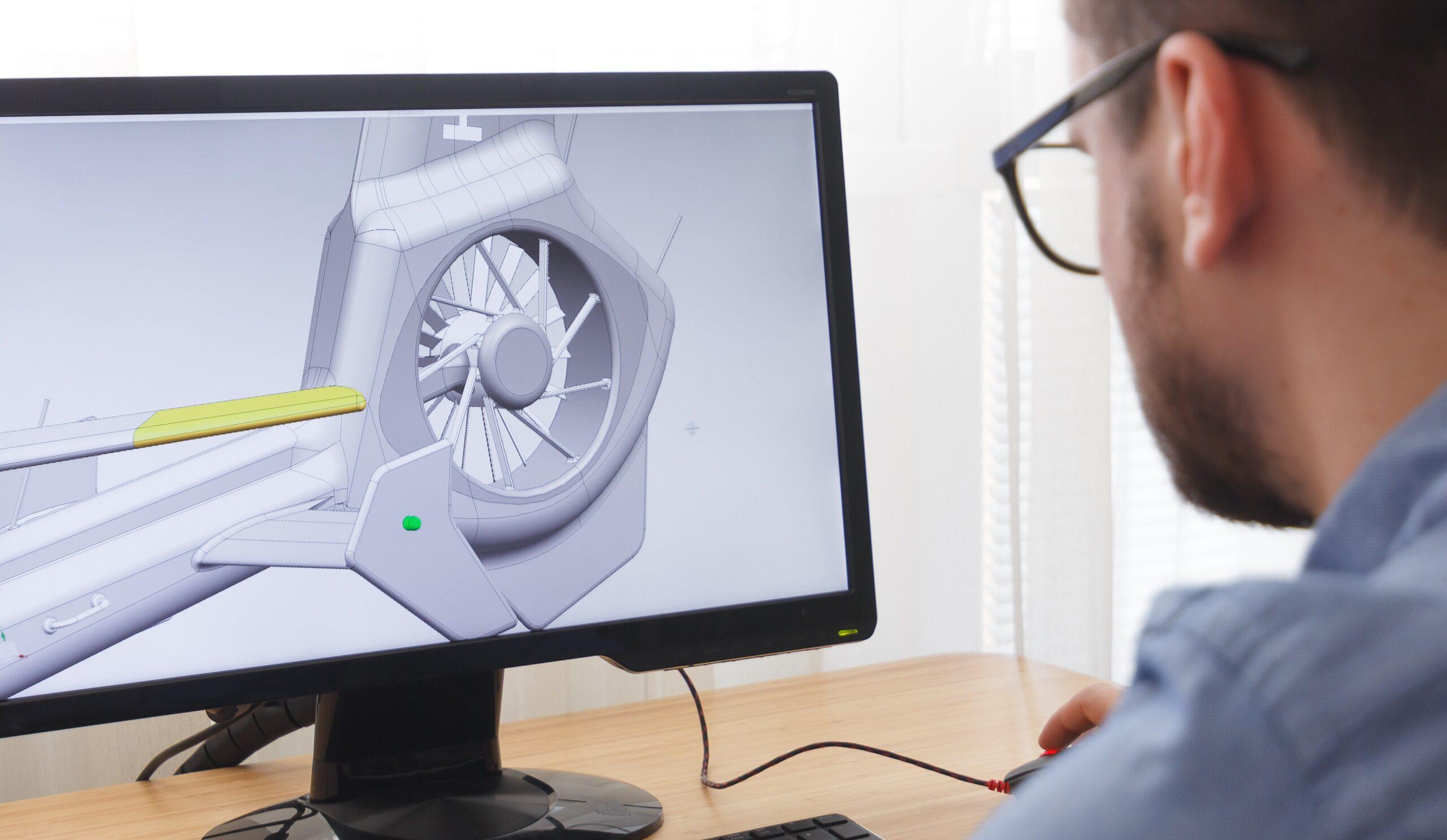

In the world of rapid prototyping, each project poses unique challenges: complex shapes, mechanical requirements, aesthetic needs, or cost constraints. To respond to these variables, more and more designers and engineers are turning to hybrid manufacturing strategies, combining 3D printing and CNC machining in the same prototype.

In this article, we explore when it makes sense to opt for this combination of processes, what advantages it offers over using a single technology, and how to avoid common mistakes when planning a prototype with mixed materials.

Advantages of combining 3D printing and CNC machining in rapid prototyping

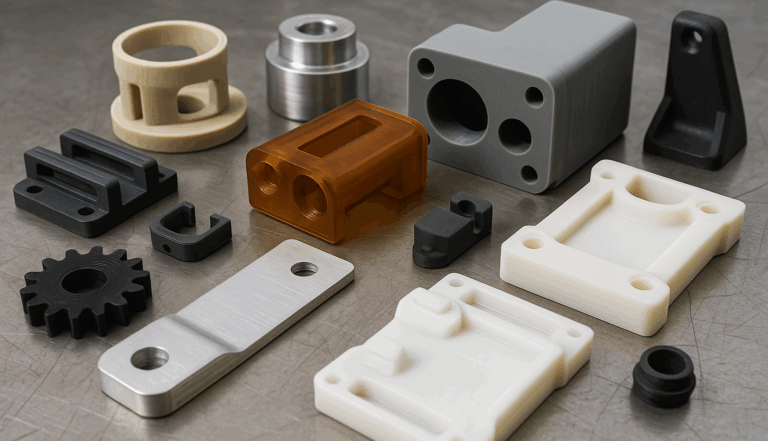

When 3D printing and CNC machining are combined in a single part or set of parts, the strengths of each technology can be leveraged:

- 3D printing allows for complex, internal, or even flexible geometries, with very competitive lead times and costs thanks to advances in industrial 3D printers.

- CNC machining offers superior precision, better surface finish, and allows you to work with high-performance metallic or technical materials through online CNC manufacturing.

This combination allows, for example, the main body of a product to be manufactured using 3D printing materials such as polyamide, and a machined anodized aluminum cover to be added to improve structural rigidity or visual perception.

Another common case is to use printed components to validate adjustments or fits, and machine the functional parts that will be subjected to stress or friction in actual use.

When does it make sense to use mixed materials in parts manufacturing?

Hybrid prototyping strategies are especially useful when:

- The aim is to optimize the cost of the prototype without compromising certain technical or aesthetic features.

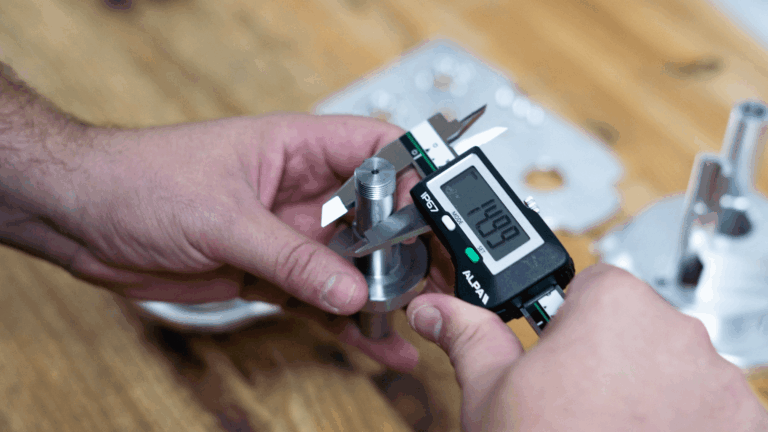

- It is necessary to validate a functional part (e.g., a contact area, threads, bearings) that requires tighter tolerances or specific materials using machined parts.

- Some parts require a careful final finish, such as buttons, covers, or visible panels.

- The total manufacturing time needs to be reduced by distributing the parts among different processes according to their complexity.

3D design and assembly considerations in hybrid processes

The use of different materials and technologies requires careful planning from the design phase onwards. Some key aspects:

- Design appropriate interfaces or connection points between printed and machined parts (tolerances, fittings, fasteners), using compatible 3D modeling tools.

- Choose materials that are compatible with each other based on their thermal or mechanical behavior.

- Consider the assembly order: some printed parts may have slight dimensional variations that must be taken into account in the design of machined components.

- Plan for post-processing operations (sanding, painting, anodizing, metal inserts, etc.) if specific functional or visual finishes are required.

Real examples of hybrid prototyping in different sectors

More and more companies are opting for hybrid solutions to accelerate product development.

In the medical sector, for example, SLA-printed housings are used in combination with machined aluminum or POM internal components, allowing both the ergonomic design and the functionality of the assembly to be evaluated.

In the automotive industry, functional prototypes are produced with printed structures and machined mating parts, streamlining assembly testing without the need for molds.

In consumer electronics, it is also common to use 3D-printed bodies together with machined covers or contact parts, optimizing cost, time, and appearance for commercial presentations or design validations.

Proto&Go!: 3D printing and CNC machining services for rapid prototyping

At Proto&Go!, we know that many projects require more than just one technology. That’s why our online prototyping platform allows you to upload your 3D files and select, in a single order, parts for 3D printing, CNC machining, or silicone molding. You’ll receive your quote in less than 24 hours, with complete clarity and no complications.

In addition, we accompany you through each phase with specialized technical advice to help you choose the most suitable materials, avoid incompatibilities, and correctly design the joints between printed and machined components. Whether you are a startup, an R&D team, or an established company, at Proto&Go! we facilitate the creation of functional prototypes with multiple technologies in a single workflow.

Upload your 3D file now and request a quote from our website!