When designing a product, it is easy to focus on form, function, and aesthetics. But when it comes time to manufacture the prototype, it is common to encounter surprises: parts that do not fit, geometries that are impossible to manufacture, or unnecessarily strict tolerances that make the process more expensive. This is where Design for Manufacturability (DFM) comes into play, a fundamental philosophy for ensuring that the leap from 3D design to physical part is smooth, fast, and free of rework.

At Proto&Go!, we see hundreds of different 3D models every day, and we know what the most common mistakes are. In this article, we share the most important DFM principles applied to prototyping, including practical recommendations for both 3D printing and CNC machining.

Do not underestimate the minimum thicknesses (and do not push them to the limit).

One of the most common mistakes in 3D design is using extremely thin thicknesses. Although they may look solid on screen, in reality they can break during manufacturing or post-processing.

- In FDM, it is best to use walls that are at least 1.2 mm thick.

- In SLA or resins, although precision is higher, walls thinner than 0.8 mm are fragile.

- In CNC machining, avoid walls less than 1 mm thick, except for very simple geometries.

A suitable thickness prevents deformation, breakage, and finishing problems.

Respect the exit angles and avoid impossible cavities.

In prototypes intended to become molded or machined parts, draft angles are key. Although in 3D printing “anything is possible” in many cases, if the project will evolve into industrial manufacturing, it is necessary to include them from the outset.

- For molded plastics: leave between 1° and 3° of clearance.

- For deep machined cavities: take into account the length and diameter of the tools.

- If a cavity can only be manufactured with a tool that is too long and thin, deflection could ruin the finish.

Design realistic tolerances based on the technology used.

The most common mistake when moving from a 3D model to a prototype is to assign overly strict tolerances. This makes manufacturing more expensive without adding any real value. Ideally, tight tolerances should only be defined for assembly surfaces or critical areas.

Approximate values:

- FDM: ±0.3 to ±0.5 mm.

- SLA/MJF/SLS: ±0.1 to ±0.2 mm.

- CNC: standard tolerances ±0.1 mm; high precision up to ±0.01 mm.

Use joints and fittings compatible with prototyping

Many designs include clips, tabs, very fine threads, or snap-fit connections that work in mass production but not in prototyping. In prototyping, simplicity is usually your ally.

- If you design clips: avoid sections that are too thin.

- For fittings: allow clearances of 0.2 mm to 0.5 mm depending on the material and technology.

- For threads: consider using threaded inserts instead of printing them.

Avoid minor details or superficial texts

Texts, logos, and very fine details may be lost in the 3D printing process or require overly delicate CNC tools.

- In 3D printing: use reliefs of at least 0.4 mm.

- On CNC: design texts with 1 mm or larger cutters.

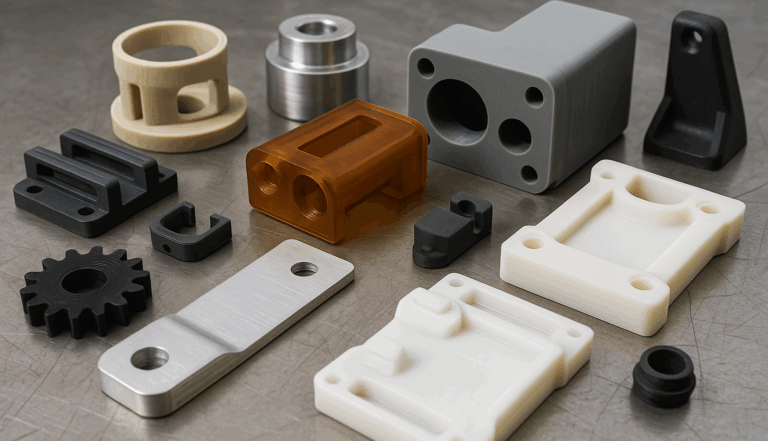

Adapt the design to the materials

Each material has different mechanical, thermal, and stiffness properties. Designing a part without considering its final material often leads to deformation, cracking, or failure during assembly.

Quick examples:

- ABS tolerates impacts better than PLA, but it has more shrinkage.

- Rigid resins offer great detail but are fragile.

- MJF and SLS nylons (PA12) offer an excellent balance between strength and flexibility.

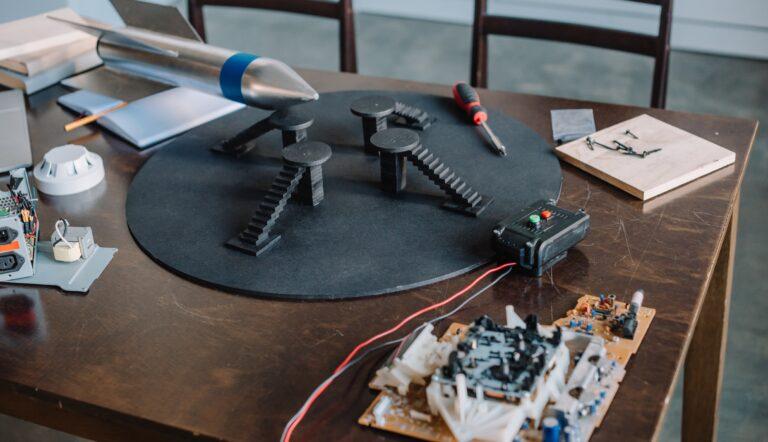

Always validate with a prototype before industrializing

The best DFM is to iterate. No 3D model can replace a real part.

Before moving on to molds, final designs, or mass production, always validate with a prototype. Manufacturing an intermediate version using 3D printing or CNC machining will allow you to detect flaws that are invisible on screen.

Our team reviews your 3D file, detects geometric risks, and advises you on the best prototyping technology for your part, whether it be 3D printing or CNC machining.

Designing with manufacturability in mind not only saves costs: it speeds up your development and brings your product closer to market.

At Proto&Go! we understand that every customer needs speed, clarity, and technical confidence. Our online prototyping platform allows you to easily upload your 3D files, select from technologies such as 3D printing, CNC machining, or silicone molding, and receive a quote in less than 24 hours.

Upload your file and receive your quote online now.