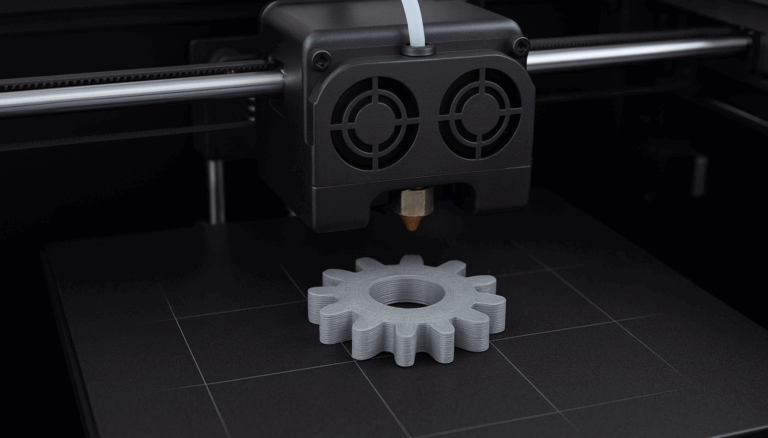

3D printing has revolutionized the way companies approach product development, from rapid prototyping to creating customized solutions through additive manufacturing.

However, when implementing 3D printing services, it is common to make mistakes that can slow down projects or increase costs. Below, we explore the most common mistakes and how to avoid them, ensuring the best use of this technology.

Lack of planning in additive manufacturing

One of the main obstacles for companies starting to implement 3D printing services is the absence of a clear strategy. Without a defined vision, it is easy to invest in industrial 3D printers or 3D printing materials that do not fit the real needs of the project.

To avoid this mistake, it is crucial to answer key questions:

- Is the main objective rapid prototyping, product customization or exploring new applications in additive manufacturing?

- What type of 3D printing materials and technologies will be needed to meet the requirements?

A well-defined approach allows the right equipment to be chosen. For example, a startup focused on rapid prototyping might benefit more from versatile equipment rather than high-priced industrial 3D printers, while the wrong choice of materials could compromise both the functionality and durability of products.

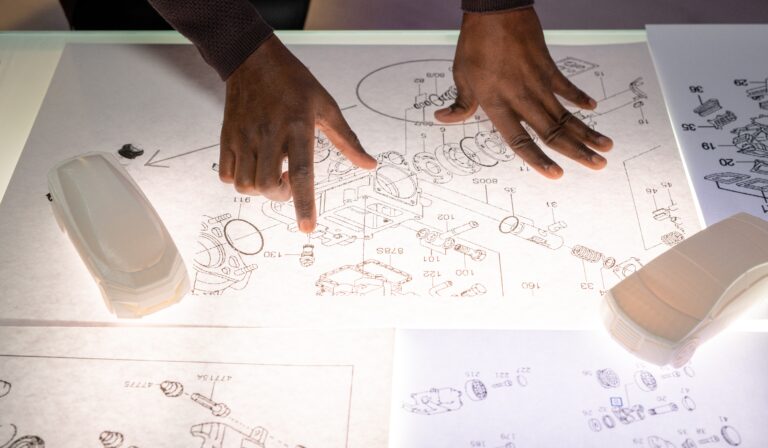

Underestimating 3D design and modeling

A recurring mistake among companies is to ignore the relevance of 3D design and 3D modeling in the success of their 3D printing projects. These disciplines are essential to take full advantage of the technology’s potential.

Improper design can result in defective parts, material waste and extended production times. Having professionals trained in 3D printing and 3D scanning software is a key investment to create optimized and functional models, reduce iteration cycles and adapt designs to the unique capabilities of industrial or desktop 3D printers.

In addition, the use of advanced 3D printing software tools makes it possible to design complex geometries, maximize resources and ensure quality at every stage of the process.

Ignoring the hidden costs of the 3D printing process

Implementing 3D printing services involves more than the initial investment in equipment: factors such as maintenance, training in 3D design and 3D modeling, and the incidentals associated with using industrial 3D printers can add to the expense.

To avoid financial surprises, it is essential:

- Include all associated costs in the budget, from 3D printing materials to 3D printing software upgrades.

- Anticipate maintenance and parts replacement needs on printers.

- Establish a fund for emergencies and additional testing.

Efficient resource management ensures the long-term viability of the project, making it possible to take full advantage of the capabilities of additive manufacturing.

3D printing at Proto&Go!

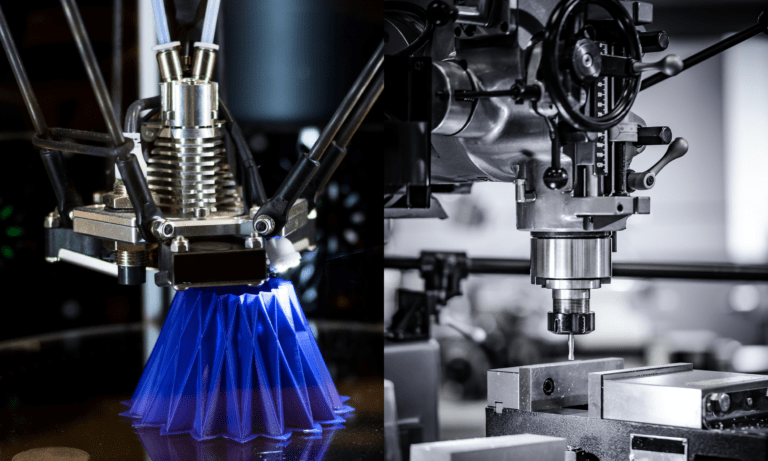

All in all, we can say that 3D printing promises to continue solving complex problems in industries at different scales. This manufacturing method will continue to evolve and add versatility and efficiency in many different ways.

At Proto&Go! we are specialized in MJF (Multi Jet Fusion) printing and we aim to provide the best 3D printing service for the development of your parts.

What are you waiting for? Request your quotation now and receive your quote in less than 24 hours!