In the aerospace industry, 3D printing and 3D scanning have revolutionized component production, enabling the creation of parts that are both lightweight and durable.

This innovation has resulted in a significant reduction in aircraft weight, which in turn improves fuel efficiency. On the other hand, the ability to produce customized parts specifically designed for optimal performance are two advantages of additive manufacturing that greatly benefit the aerospace industry.

These technologies have also transformed the development and prototyping processes in the aerospace industry. Rapid and cost-effective printing of prototypes and components has significantly accelerated the design cycle. This enables companies to respond with greater agility to changing market needs and rapid technological advances.

Benefits of additive manufacturing in the aerospace industry

Today, 3D printing offers a wide range of advantages to the aerospace industry thanks to its customization capabilities and short manufacturing times.

Some of its main benefits are:

-

- Customization of tailor-made components: 3D printing allows the creation of customized components adapted to specific needs.

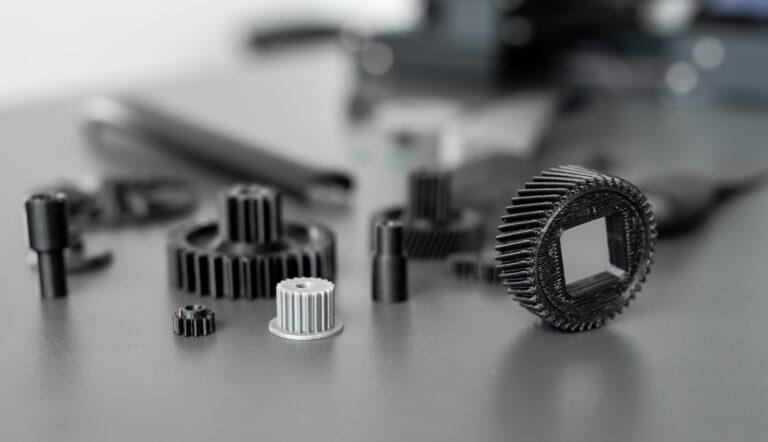

- Designs with greater complexity: thanks to additive manufacturing, it is also possible to produce complex geometries that would not be possible to achieve using other manufacturing methods.

- Component weight reduction: one of the great advantages of 3D printing in the aerospace industry is undoubtedly the ability to design parts with optimized internal structures (such as meshes or grids), which allows for a great reduction in component weight.

- Manufacture of parts with high temperature resistance: the needs of the aerospace sector place certain requirements on 3D printed parts, such as high resistance to extreme temperatures.

- Reduced costs and manufacturing time: 3D printing reduces production costs by eliminating the need for expensive tooling and molds. In addition, it also shortens delivery times.

- Sustainability in the production process: additive manufacturing generates less waste than other manufacturing processes such as CNC machining, since it only uses the material needed to build the part.

What applications does 3D printing have in the aerospace industry?

The aerospace industry can adopt 3D printing technology for numerous applications as it improves component design and production.

First, as we mentioned earlier, 3D printing is ideal for manufacturing structural parts with complex geometries such as internal aircraft components, brackets or ducts.

On the other hand, just as in other industries, in aerospace, 3D printing is also used for rapid prototyping and design validation. Thanks to this technology, engineers can improve quickly and make the necessary adjustments or corrections in a much shorter time. This speeds up the development process and also reduces costs.

At Proto&Go! we provide the best service for the development of your parts and prototypes through additive manufacturing. Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!