CNC machining technology has undergone an enormous evolution over the last decades. And it is expected to continue to transform the manufacturing of parts and prototypes in the future. Specifically, in the coming years, several key trends are expected to drive efficiency, accuracy and versatility in the CNC machining process.

One of the most interesting trends is the incorporation of Artificial Intelligence and Machine Learning. Soon, we may see greater use of AI algorithms for optimizing machine scheduling and control and for rapid fault detection.

On the other hand, it is worth highlighting environmental awareness, which will continue to be an important issue in the coming years, especially in the machining industry. New CNC machines are increasingly focusing on energy efficiency and waste reduction.

Finally, the hybrid CNC machines stand out for their great versatility. These machines are expected to be a major trend in the future, as they combine the capabilities of traditional machining with additive technologies.

What is the difference between 3-axis, 4-axis and 5-axis CNC machining?

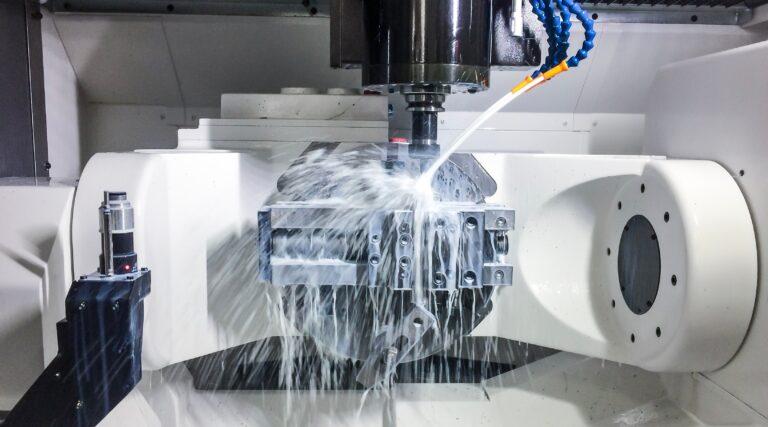

Today, CNC milling machines are tools with the ability to manufacture parts and prototypes quickly and reliably. This is because they can move along several axes of travel while maintaining dimensional pressure.

CNC milling machines are therefore classified according to the number of axes with which they operate. The most common machines are 3-, 4- and 5-axis machines. This factor determines both the characteristics of the manufactured parts and the efficiency and precision in production.

At Proto&Go! we offer industrial machining solutions thanks to our state-of-the-art machinery, which have 3, 4 and 5-axis capabilities.

CNC machining in the medical industry

The medical industry has been undergoing some remarkable transformations and it is clear that it is a sector that is continually evolving.

The impact of CNC machining on this industry is enormous, as it helps to create new and innovative medical devices. This technology is excellent for creating customized, personalized solutions quickly, which is essential in the medical field.

In short, it is clear that CNC machining plays a key role in this industry thanks to its precision and consistency, enabling everything from the production of surgical instruments to the manufacture of prostheses customized to the user’s needs.

Tips for optimizing CNC machining and reducing your costs

For an engineer, designer or buyer, a long lead time on your parts can be frustrating and nerve-wracking.

Today, for companies in the industrial sector, it is increasingly important to increase the speed of innovation of new products. Fortunately, there are several ways to reduce lead times in the CNC machining process, such as choosing suppliers that handle complex requirements at high speed, prioritizing quality control to shorten part lead time or optimizing communication with suppliers, among others.

All in all, we can say that the future of CNC machining looks quite promising and, above all, full of changes and innovations. The focus is on improving automation, efficiency and versatility in manufacturing and machining of parts and prototypes, which will be of great benefit to the industry.

At Proto&Go! we offer the best CNC machining services for your parts and prototypes. In addition, through our website you can receive your quote in less than 24 hours.

What are you wating for? Request your quote now!