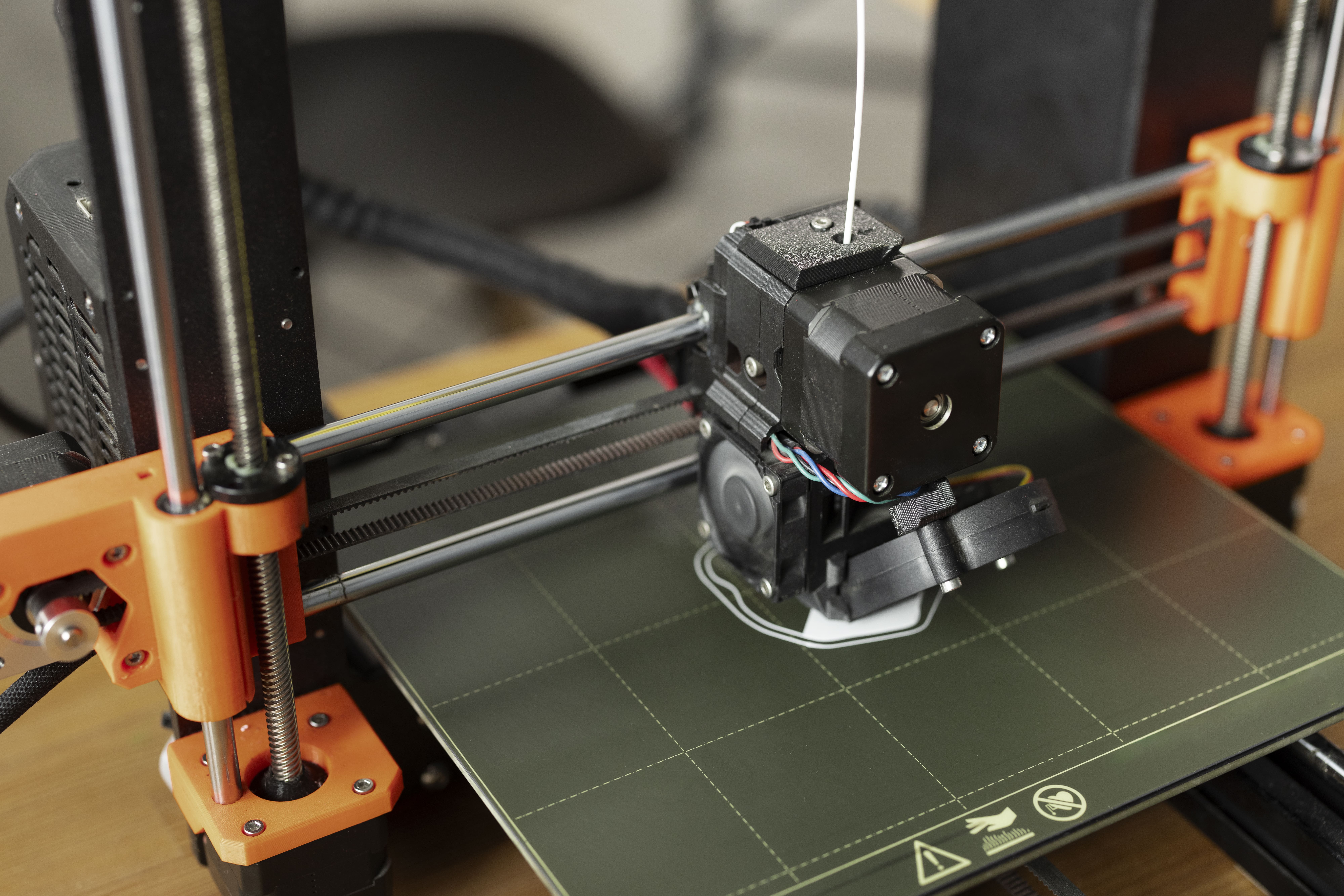

Additive manufacturing, commonly known as 3D printing, has revolutionized several industries by enabling the creation of parts and products in a faster and more customized way. However, despite its numerous benefits and advances, there are several myths surrounding this emerging technology.

In this article, we tell you five of the most common myths about additive manufacturing, with the aim of providing a clearer and more accurate picture of its capabilities and limitations.

Additive manufacturing systems produce parts ready for use

One of the most common myths is that additive manufacturing or 3D printing systems produce ready-to-use parts or complete products. While there are exceptions, most parts manufactured by 3D printing require other subsequent procedures such as the removal of support material, surface finishing or the addition of a clear coat.

Therefore, most of the time, 3D printing is used for manufacturing an element of a product rather than a complete functional product. A clear example is some of the parts for machines, automobiles or even airplanes. These 3D printed parts contribute to or support the final product, but many other parts are manufactured using more conventional manufacturing methods such as CNC machining.

3D printing is fast and economical

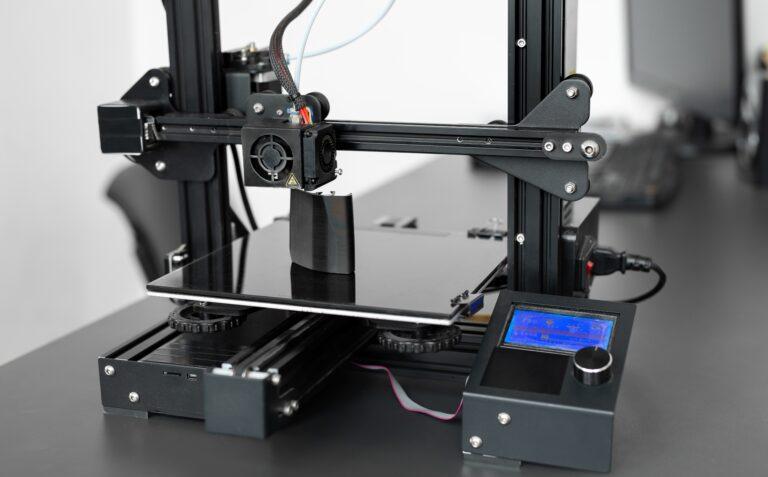

The myth that additive manufacturing is fast and economical is true only in the case of manufacturing relatively small parts and in short series. This technology reduces or eliminates the need for tooling (such as molds) that can increase both lead times and costs. It is therefore possible to produce the first parts quickly and at a lower cost than with other manufacturing methods.

On the other hand, compared to large volumes of parts manufactured by injection molding, 3D printing can be slower and more expensive.

Parts are not as good as those made by other methods

Another myth about this technology is that parts made by 3D printing are not as good as those made by conventional methods. In this case, it may depend on several factors such as the type of 3D printer used, the materials…

Even so, thousands of parts have already been manufactured by additive manufacturing with a high precision and quality and for numerous applications such as: medical components, industrial machines, automotive parts…

Few materials are available for the manufacture of 3D printed parts

On the other hand, there is also the myth that there are few materials available. In this case we can say that it was true years ago, but, nowadays, numerous material options have been commercialized for additive manufacturing.

Additive manufacturing systems can print human organs

Finally, there is a myth that additive manufacturing systems can print human organs. This statement could be considered one of the biggest myths related to 3D printing. Although some first samples have been produced, this project is still in the research and development phase and is still a great challenge for the professionals.

In addition to those mentioned above, there are many more myths about 3D printing technology such as that additive manufacturing is a process that is done only by pushing a button, that all additive manufacturing systems are all similar, or even that most homes will have a 3D printer in the future.

Additive manufacturing at Proto&Go!

At Proto&Go! we provide the best service for the development of your parts and prototypes through additive manufacturing. In addition, we are specialized in printing by Multi Jet Fusion or MJF, the latest technology of the HP company specially designed for industrial applications.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!