3D printing technology offers numerous advantages such as production speed, a wide variety of materials or the creation of complex parts. However, one of the main concerns when choosing this method of manufacturing parts and prototypes is its cost.

Reducing the cost of the additive manufacturing process is possible by optimizing the design, selecting the right manufacturing options and the finishing and materials used.

In this article we highlight some useful tips or strategies to reduce the cost of 3D printing.

Cost reduction at the product design stage

There are several ways to achieve cost reductions through product design.

First, a good way to use less material and therefore reduce the cost is to hollow out a 3D model. In this way, the material inside the part is eliminated and, in addition to reducing the cost, a lighter part is obtained.

On the other hand, it is essential to take into account the size of the 3D printed part. If the size of your prototype is not important, since it is simply a visual prototype, a good way to reduce the cost would be to reduce the scale of the model.

Reducing costs by selecting appropriate options

The best way to reduce material costs is to choose the right material according to the needs of each project. If the printed part is only a visual model, it may not be necessary to print it on a high performance material, which will always have a higher price.

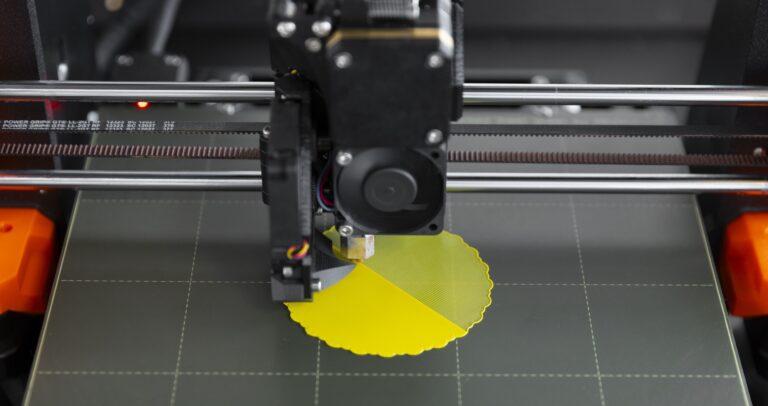

Choosing the right process for each project can also help reduce cost. Technologies such as FDM and MJF are much more economical than others such as SLS. Therefore, it is necessary to consider, once again, whether the use of 3D printing is intended for prototyping or visual modeling or whether, on the contrary, it requires high-end printing.

Finally, it is necessary to consider the volume of production. 3D printing is the best option for the manufacture of short series of parts or for individual units. On the other hand, for larger batches, the best option would be to opt for other technologies such as CNC machining.

Reduced costs in the post-processing or finishing phase of the part

Finishing can also increase the price of 3D printing. On the one hand, finishes such as dyeing are often a more economical way to color parts compared to painting. However, the paint provides longer lasting color and higher quality.

In short, the choice of one option or another will always depend on the needs and requirements of each project, but we must always take into account the strategies that allow us to optimize the process and save on the costs involved in 3D printing technology.

At Proto&Go! we offer the best 3D printing service for your parts and prototypes using MJF (Multi Jet Fusion), a technology specially designed for industrial applications.

Contact us or request your quote now online!