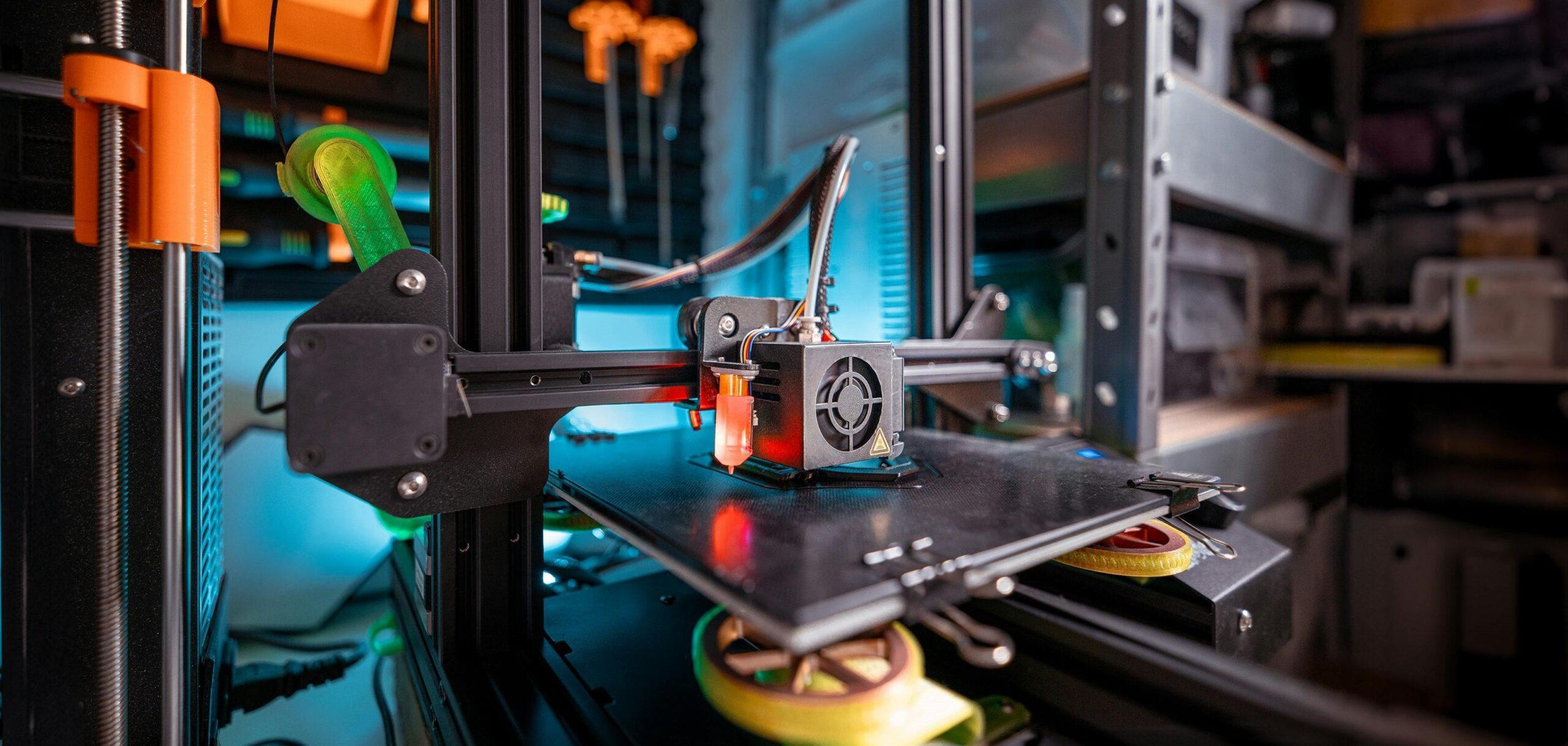

. 3D printing has revolutionized the field of manufacturing, enabling the creation of complex objects quickly and efficiently. One of the most promising innovations in this field is hybrid 3D printing. This approach combines different manufacturing methods, thus optimizing the production process.

In this article, we will explore what hybrid 3D printing is, how it works and its applications in various industries.

The synergy of different manufacturing methods

Hybrid 3D printing integrates additive and subtractive manufacturing technologies. Generally, this involves combining 3D printing processes, such as HP MJF (Multi Jet Fusion) 3D printing, with CNC milling. Additive manufacturing allows complex shapes to be created layer by layer, while milling provides a high-precision, high-quality finish.

This synergy not only optimizes production, but also makes it possible to correct errors in the milling phase, thus improving final product quality. The ability to combine industrial 3D printing with Multi Jet Fusion and CNC milling gives manufacturers a significant competitive advantage in terms of time and accuracy.

Benefits of Hybrid 3D Printing

Acceleration of production time

One of the main benefits of hybrid 3D printing is the acceleration of production time. By integrating additive and subtractive methods, companies can significantly reduce the manufacturing cycle. This means that, instead of waiting for a production process to be completed separately, both methods can be performed simultaneously or in sequence, thus optimizing the workflow.

Quality improvement

Quality is crucial in modern manufacturing, especially in sectors where precision is vital, such as aerospace or medical. High-quality industrial 3D printing with MJF enables precise adjustments to be made during the milling phase, ensuring that components meet strict specifications and tolerances. This approach not only minimizes material waste, but also improves the sustainability of the process.

Flexibility and customization

Hybrid 3D printing also offers unprecedented flexibility in production. With the ability to create customized designs, manufacturers can respond quickly to market demands. In the medical sector, for example, additive manufacturing with Multi Jet Fusion enables the creation of prostheses and implants that perfectly match the patient’s anatomy, significantly improving clinical outcomes.

Applications in multiple industries

Hybrid 3D printing is being adopted in multiple industries, demonstrating its versatility and effectiveness.

- Aerospace: In this industry, hybrid 3D printing is used to produce components that are both lightweight and strong. Combining advanced 3D printing with HP Multi Jet Fusion and CNC milling enables companies to manufacture complex parts that improve fuel efficiency and aircraft performance.

- Medical sector: The medical sector is seeing a big impact thanks to hybrid 3D printing. Customized medical devices can be created that meet strict regulations and quality standards. For example, implants and prosthetics designed by prototyping with Multi Jet Fusion 3D can be tailored to the specific needs of each patient, resulting in a better fit and greater satisfaction.

- Automotive industry: Finally, the automotive industry is also embracing hybrid 3D printing to accelerate the development of new models. Industrial 3D printing services enable manufacturers to rapidly prototype and test in an efficient manner. This agility in the design and production process results in more innovative and efficient vehicles.

In short, we can say that hybrid 3D printing is setting a new direction in modern manufacturing, combining the flexibility of additive printing with the precision of subtractive methods. This approach not only improves quality and speeds up production, but also enables unprecedented customization in a variety of industries. As more companies begin to implement advanced 3D printing with HP Multi Jet Fusion, new possibilities in product development will open up, taking manufacturing to a whole new level.

At Proto&Go!, as a leading 3D printing company, we offer 3D printing solutions for companies looking to optimize their production process. With our industrial 3D printing services, we are ready to help companies transform their ideas into tangible realities, improving their competitiveness in a constantly evolving market.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!