Automation in machining workshops has experienced exponential growth in recent years. The integration of robots and intelligent systems has made it possible to optimize processes, improve precision and reduce operating costs. This transformation not only responds to the search for greater efficiency, but also to the need to adapt to the growing demand for customization in manufacturing and the shortage of skilled labor.

The impact of robotics on CNC machining

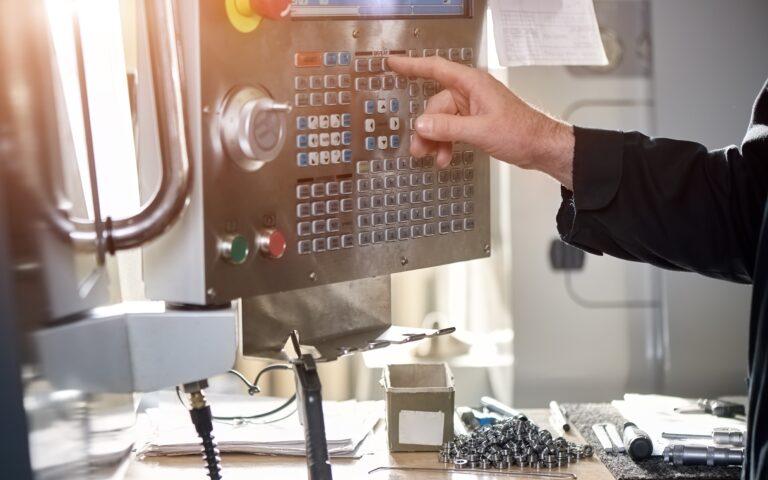

Industrial robots have revolutionized the machining industry by taking on repetitive and high-risk tasks, allowing operators to focus on higher value-added functions. Today, collaborative robots (cobots) are gaining ground thanks to their ability to interact with humans in a safe and flexible manner.

Some of the most common applications of robotics in machine shops include:

- Loading and unloading CNC machines: Robots can feed and remove parts from lathes and milling machines, reducing downtime and increasing productivity.

- Polishing and deburring: The precision and consistency of the robots in these tasks improve the quality of the finish and reduce material waste.

- Inspection and quality control: The artificial vision integrated in the robots allows automated inspection of parts in real time, ensuring high quality standards.

Intelligent systems to optimize the production of machined parts

Beyond robotics, the implementation of intelligent systems has transformed the way machining shops manage their processes. Thanks to artificial intelligence and real-time data analysis, it is possible to optimize production and minimize errors.

One of the most relevant advances is predictive maintenance, which makes it possible to anticipate machinery failures by means of sensors and data analysis, avoiding unexpected stoppages and reducing repair costs.

Another key aspect is automatic machining programming, where AI generates optimal paths for cutting tools, reducing wear and improving efficiency in each operation. In addition, manufacturing execution systems (MES) are revolutionizing shop floor management by connecting all machines and processes in a digital network. This allows total control of production, facilitating data-driven decision making and improving traceability of each manufactured component.

These advances not only increase productivity and reduce operating costs, but also ensure greater production accuracy. As technology advances, machining shops that adopt these intelligent systems will be better positioned to meet the challenges of the industry and satisfy the growing demand for customized products with high quality standards.

Benefits of automation in machining shops

The integration of robots and intelligent systems in machining shops brings multiple benefits:

- Increased productivity: Automation reduces downtime and allows uninterrupted shift operation, significantly increasing production capacity.

- Reduced operating costs: Process optimization and reduced material waste lower manufacturing costs.

- Higher precision and quality: Intelligent systems ensure repeatability and accuracy superior to manual work.

- Flexibility and market adaptation: Collaborative robotics and artificial intelligence facilitate product customization without affecting efficiency.

- Occupational safety: Automation reduces operators’ exposure to hazardous and repetitive tasks, reducing the risk of accidents and illnesses.

Challenges and future of automation in machining

Despite their advantages, the implementation of robots and intelligent systems in machine shops presents some challenges. The initial investment can be high, which represents a barrier for small and medium-sized companies. In addition, the integration of new technologies requires specialized training to maximize their potential.

However, the future of automation in machining is promising. The combination of artificial intelligence, Internet of Things (IoT) and additive manufacturing will enable an unprecedented level of customization and efficiency. As these technologies become more accessible, their adoption will expand, driving competitiveness and innovation in the industrial sector.

At Proto&Go! we offer the best CNC machining service for your parts and prototypes. You can request your quotation through the form on our website in a quick and easy way.

What are you wating for? Request your quote now!