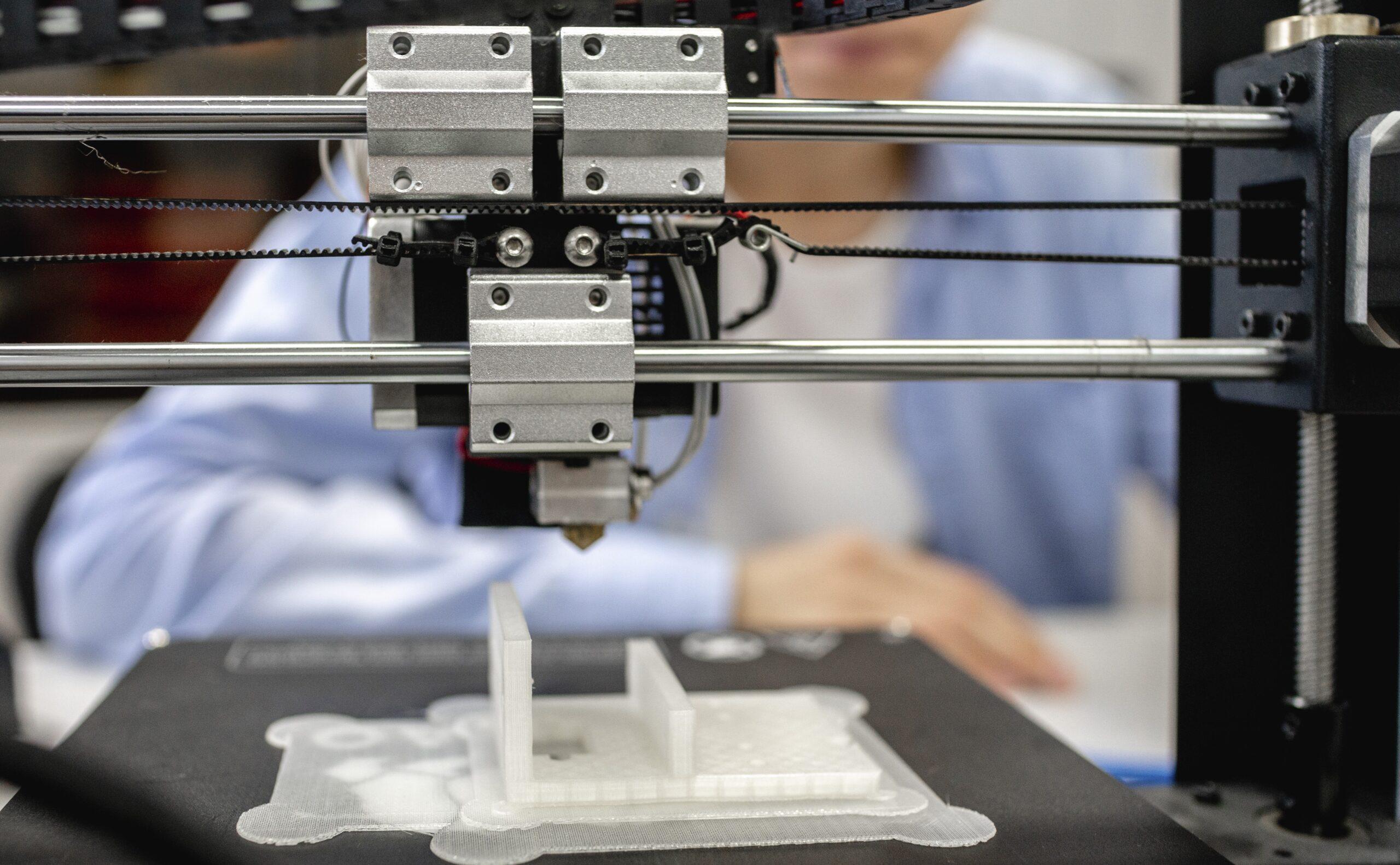

. 3D printing, or additive manufacturing, offers advantages and applications for different sectors. This new technology has proven to be very useful in the production of products and components, from those used in healthcare to prototyping in industrial design.

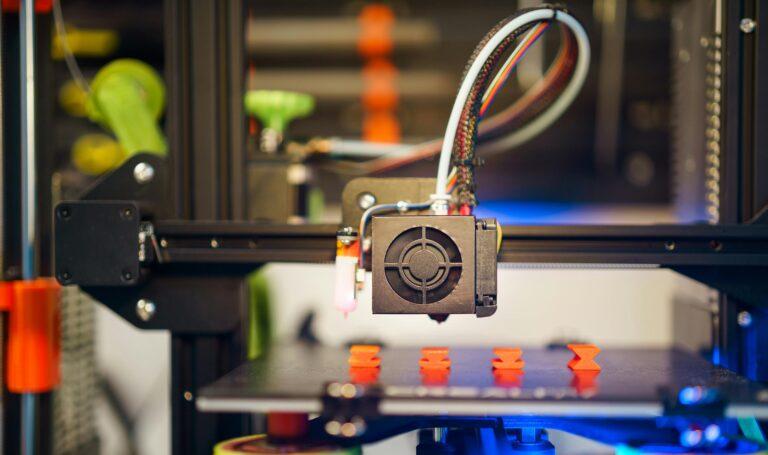

There are a variety of techniques used for 3D printing, but at Proto&Go! we use MJF (Multi Jet Fusion) printing. It consists of a more advanced technology with which parts are manufactured in both Polyamide PA12 and TPA.

Advantages of 3D printing

- The strength of the materials: unlike other additive manufacturing technologies, parts printed with HP Multi Jet Fusion are perfectly isotopic, i.e. the strength offered by the part is the same in any of its three axes and therefore in any direction of stress.

- Production speed: layers take seconds to print thanks to the print head. In addition, the fusing process is integrated into the printing process itself, so there are no additional operations that are not productive and efficient.

- The high resolution: due to the use of microdroplets, the HP Multi Jet Fusion 3D printer has a high resolution, which is unmatched by any other technology. In addition, the resolution and surface quality can be extended by using smaller layer heights.

- Wide variety of materials: in addition to parts in rigid and resistant materials such as PA12, it is also possible to obtain flexible parts in TPA with a shore 90A. This material is ideal for the manufacture of bellows, seals or any other component that requires a certain elasticity.

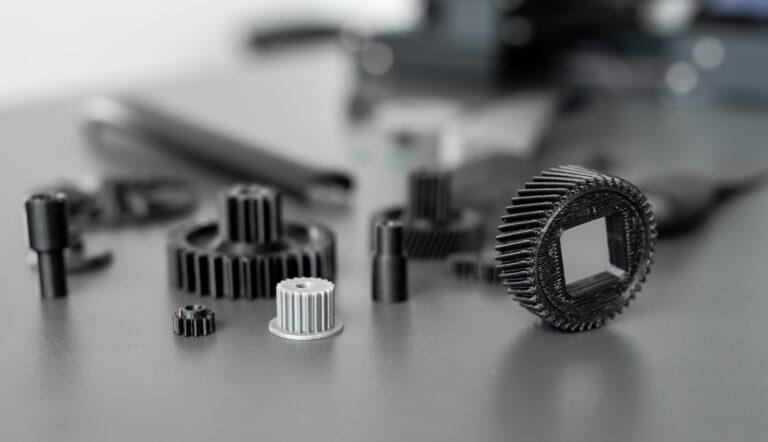

- The creation of complex geometries: 3D printing, unlike traditional machining, can create more complex designs and lighter parts.

- Little material waste: unlike other processes such as subtractive manufacturing, which eliminates material for the production of parts, 3D printing is a solution that allows adding only the material necessary for the production of the part.

- The sustainability of the process: the 3D printing process is environmentally friendly as it uses fewer materials and can recycle most of the plastic supports.

What are the applications of additive manufacturing?

3D printing is a very versatile solution for a wide range of applications. Here are some of them:

Firstly, it is an ideal process for rapid prototyping due to its production speed and wide range of materials. At the same time, it is also an excellent process for the manufacture of industrial end-use items. This technology allows the manufacture of series of parts in relatively short production times and without the need for high investments in molds or tooling.

On the other hand, the design and manufacturing engineering sector is one of the areas where 3D printing has had the greatest impact. This technology has succeeded in simplifying the part creation process and makes it easier as engineers no longer have to deal with the many limitations associated with subtractive manufacturing technologies.

Finally, there are many other sectors where additive manufacturing is of great help. Among them, the medical sector, where this technology is making great progress and has managed to create new prototypes for the development of products in medicine and dentistry (such as implants for knee or hip operations, customized prostheses, orthopedic insoles…). Also the construction sector, where, beyond making prototypes of buildings before their construction, 3D printing is present in some projects of house or building constructions with large-scale printers.

In short, 3D printing is an ideal process for the production of prototypes and short series in polyamide thanks to its numerous advantages and its growing and continuous evolution in different sectors, especially in industrial design engineering.

At Proto&Go! we make it easy for you.

For more information or to request your quote visit our website!