Ordering a prototype seems like a simple task: you choose the technology, upload the file, and wait for the result. But the reality is that without the right information, it’s easy to make mistakes that can affect quality, cost, and delivery times.

In this article, we tell you about the most common mistakes when requesting a prototype and give you the keys to avoiding them, whether you are an experienced designer or this is your first project.

Submitting an incomplete or poorly prepared file

One of the most common mistakes is uploading CAD files without checking that they are ready for manufacturing. Typical errors include:

- Open or unclosed surfaces.

- Incorrect scale.

- Geometries that are impossible to manufacture (walls that are too thin, for example).

- Files without a clear name or without an updated version.

How can this be avoided?

Check the model carefully before uploading it. If possible, export it in STEP or STL format depending on the chosen technology, and make sure that the units of measurement are correct. Always include a final version validated by the designer.

Not defining the objective of the prototype

Not all prototypes serve the same purpose. A visual prototype does not require the same precision or materials as a functional or structural one. Many errors arise from not communicating what is expected of the prototype: is it for display at a trade show? Will it be subjected to mechanical stress? Does it need to withstand heat?

How can this be avoided?

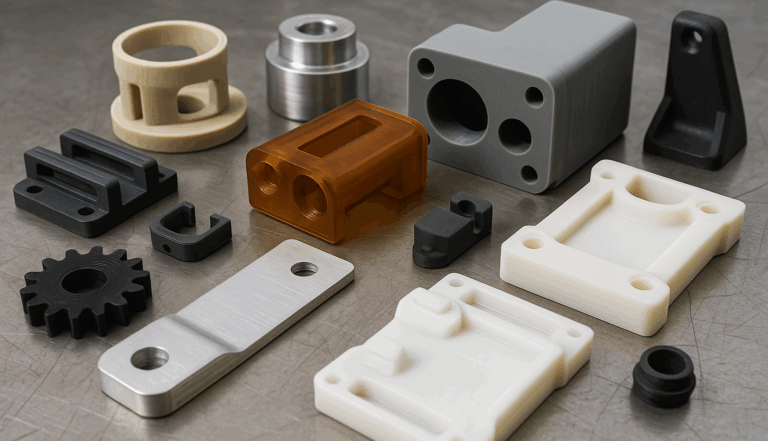

Clearly indicate the use of the prototype. This allows you to select the appropriate process (3D printing, CNC machining, silicone, etc.) and adjust materials, tolerances, and finishes according to actual needs.

Choosing the wrong material

Another common mistake is choosing materials that do not meet the design requirements. Sometimes the cheapest option is chosen without considering whether it will be sufficiently resistant or whether it has the desired appearance.

How can this be avoided?

If you are not familiar with the materials, consult your supplier. At Proto&Go!, we advise you on the options available for your design, so you can balance cost, appearance, and functionality without compromising the result.

Not taking tolerances and adjustments into account

Designing without considering manufacturing tolerances is one of the main reasons why a prototype does not fit, does not assemble, or does not perform its function. This is especially important for parts that must fit together with others or include fastening systems.

How can this be avoided?

Adjust the CAD design with the manufacturing process in mind. If you are going to assemble parts together, consider reasonable clearances and avoid tight fits. Ask for technical advice if you have any doubts.

Not validating times and expectations

Requesting a prototype urgently without validating the actual deadlines can cause unnecessary delays or frustration. Each technology has its own timelines, and sometimes a change in material or a design adjustment can lengthen the process.

How can this be avoided?

Check the estimated delivery times from the outset. At Proto&Go!, the online request system allows you to find out the cost and delivery time in less than 24 hours. If you have critical dates, please consult us before placing your order to ensure feasibility.

Proto&Go!: your ally for error-free prototyping

At Proto&Go!, we understand that every customer needs speed, clarity, and technical confidence. Our online prototyping platform allows you to easily upload your 3D files, select from technologies such as 3D printing, CNC machining, or silicone molding, and receive a quote in less than 24 hours.

In addition, we offer expert advice at every stage, so you can choose the best material, avoid common mistakes, and receive your prototype ready to move forward with your project. Whether you are a startup, a freelance designer, or a technology center, at Proto&Go! we help you take the next step with confidence.

Upload your 3D file now and request a quote from our website!