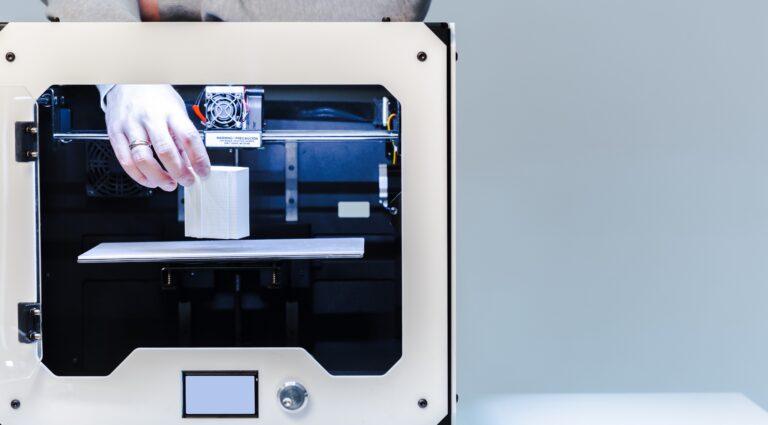

Custom 3D printing has become a must-have resource for startups looking to stand out in a competitive market. The ability to create rapid prototypes and custom end products not only accelerates development times, but also reduces costs and minimizes risks.

In this article we explore how startups can take advantage of this technology, the most common mistakes to avoid, innovative applications and the keys to choosing the right software.

Common mistakes when getting started in custom 3D printing and how to avoid them

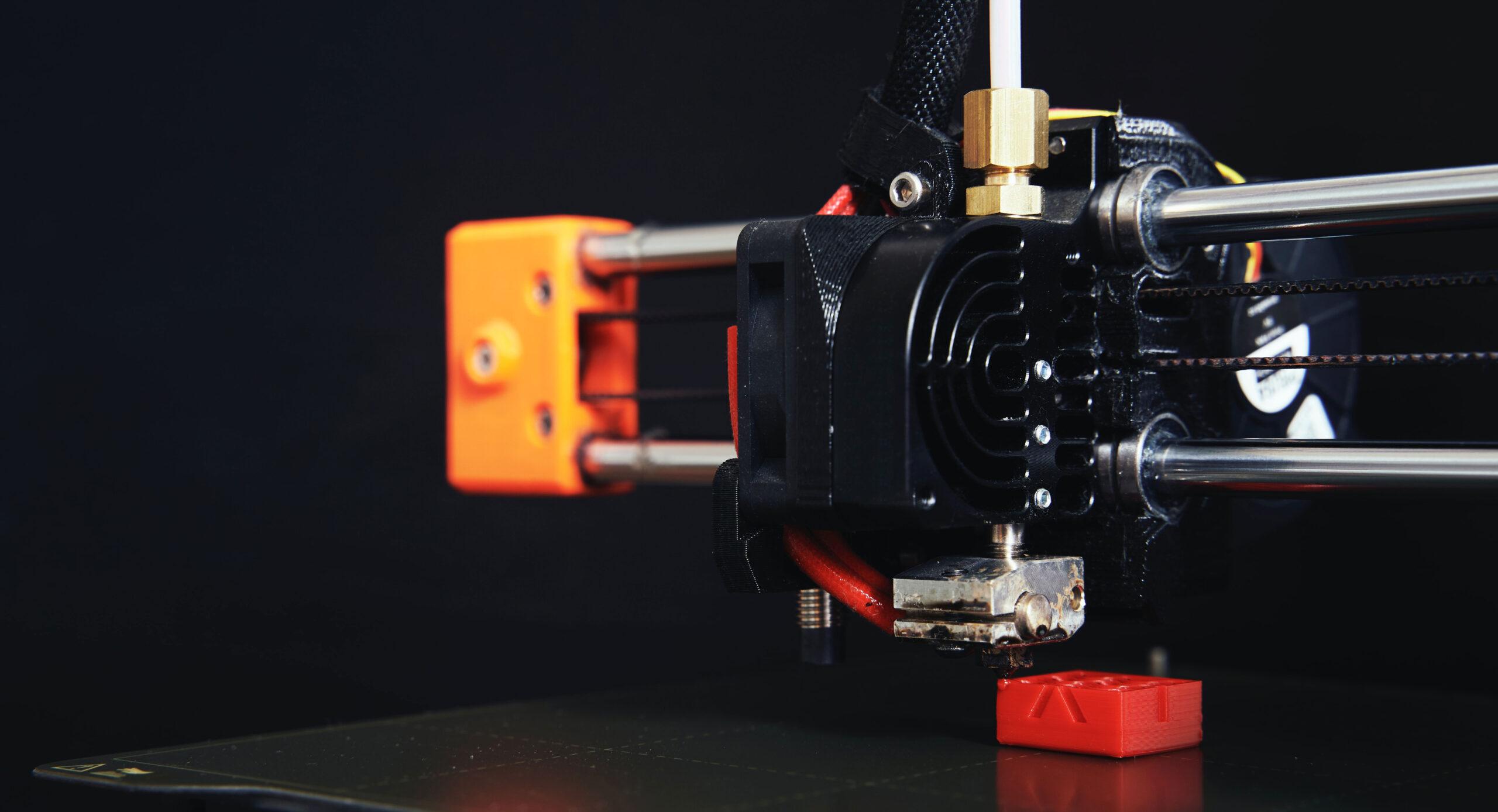

One of the biggest challenges when implementing 3D printing services is lack of planning. Many startups initiate projects without a clear vision, which can lead to choosing 3D printing materials or industrial 3D printers that do not fit their needs. To avoid this, it is essential to define from the outset whether the goal is to develop rapid prototyping, create customized products or explore new possibilities in additive manufacturing.

Another common mistake is to underestimate the importance of 3D design and 3D modeling. Both disciplines are critical to ensure successful results. Having professionals trained in 3D printing software and experienced in 3D scanning can make all the difference in optimizing time and reducing iteration costs. In addition, calculating total costs, including equipment maintenance, materials and potential contingencies, allows startups to manage their resources effectively.

Innovative applications of customized 3D printing

3D printing is redefining the boundaries of what is possible in multiple industries thanks to its flexibility and customization capabilities. In medicine, for example, 3D printing services enable the creation of prosthetics and devices tailored to the specific needs of each patient, improving their quality of life. In industrial design, innovative startups are leveraging this technology to iterate rapidly during product development, using rapid prototyping as a key tool to validate ideas before investing in mass production.

On the other hand, the automotive sector is also adopting 3D printing solutions to manufacture customized components, while in fashion and jewelry, this technology allows the design of exclusive pieces that meet the demands of an increasingly demanding market.

The versatility of 3D printing materials and the ability to work with industrial 3D printers ensure that these applications continue to grow. For startups, the key is to identify how this technology can be effectively integrated into their business models, offering unique and competitive solutions.

How to choose the right software for your custom 3D printing projects

Software is an essential component in any custom 3D printing project. Here are some key considerations for selecting the best option:

- Compatibility with your tools: Make sure the software is compatible with the type of printer and materials you plan to use. This includes file formats such as STL or OBJ and specific configuration features.

- Ease of use: For startups with small teams or limited resources, intuitive software can significantly reduce learning time.

- Advanced features: If you plan to produce complex designs, look for software with advanced capabilities such as print simulation, structure optimization or automatic support generation.

- Costs: Some programs are free or have trial versions, such as Blender or TinkerCAD. However, for more advanced projects, it may be necessary to invest in premium solutions such as SolidWorks or Fusion 360.

- Upgrades and support: Opt for tools backed by an active community and reliable technical support. This ensures that they will always be up to date with the latest industry trends and needs.

In short, we can say that custom 3D printing is a powerful tool for startups looking to innovate. The key is to carefully plan each stage of the process, from initial idea to final production, to transform concepts into tangible products that will drive your success in the market.

At Proto&Go!, as a leading 3D printing company, we offer 3D printing solutions for companies looking to optimize their production process. With our industrial 3D printing services, we are ready to help companies transform their ideas into realities, improving their competitiveness in a constantly evolving market.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!