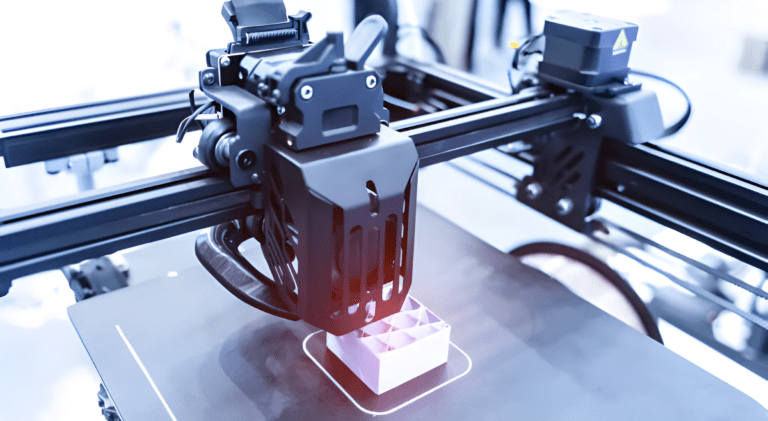

A key factor in manufacturing parts and prototypes with a solid structure using 3D printing is the infill patterns.

The filler not only improves the physical characteristics of the part, but also provides support and strength in complex structures.

What is infill in 3D printing and what is it used for?

When we talk about infill in 3D printing, we are referring to the internal patterns found inside most 3D printed parts.

Parts manufactured using 3D printing can be made with various structural patterns that partially fill the inside of the part. In other words, the parts do not need to be completely solid or hollow as in other production processes.

The infill serves to save printing time and, above all, material, as it creates a lattice structure inside a 3D printed part.

In addition, the filler can be strategically placed to provide strength where needed.

What types of fillers are available in 3D printing?

There are numerous types of fillers in 3D printing, although all have the same goal: reducing printing time and material usage.

The most common types of fillers in the 3D printing process are as follows:

- Rectilinear: this is a fill of multiple parallel lines per layer. What sets it apart from other patterns is that the lines do not cross each other on the same layer, which strengthens the piece in two dimensions. In addition, it is a faster filler compared to triangular or grid patterns.

- Rectangular: provides a structure resistant in all directions and relatively fast, since it layers perpendicularly one on top of the other.

- Triangular: this is a pattern suitable for those parts that require more resistance, since it presents superimposed triangular lines that provide resistance in two dimensions.

- Concentric: this is one of the fastest and most economical infill patterns to print, since it uses less material. However, because of this, the strength of the part is not as high as in other patterns.

- Grid: this is one of the most common types of infill in 3D printing and is ideal for prints with large, flat surfaces.

The importance of infill in 3D printed parts

Infill is an important consideration in 3D printing, as without this feature, some parts cannot be printed due to unsupported surfaces in the design.

In addition, the filler adds strength when needed and saves both printing time and material.

At Proto&Go! we provide the best service for the development of your parts and prototypes through additive manufacturing. We specialize in printing by Multi Jet Fusion or MJF, a technology that makes it possible to manufacture series of parts in very short production times and without the need for high investments in molds.

Request your quote now through our website!