The electric vehicle industry is changing rapidly thanks to technological innovations. In particular, 3D printing has become a key tool for electric car manufacturers, helping to improve production efficiency, reduce costs and accelerate prototype development. Among the most advanced technologies in this field is HP Multi Jet Fusion (MJF) 3D printing, which has revolutionized electric vehicle manufacturing by offering high-quality solutions and customization.

In this article we will explore how additive manufacturing is rapidly and steadily transforming the electric vehicle automotive industry.

Optimization of components for electric vehicles with 3D printing

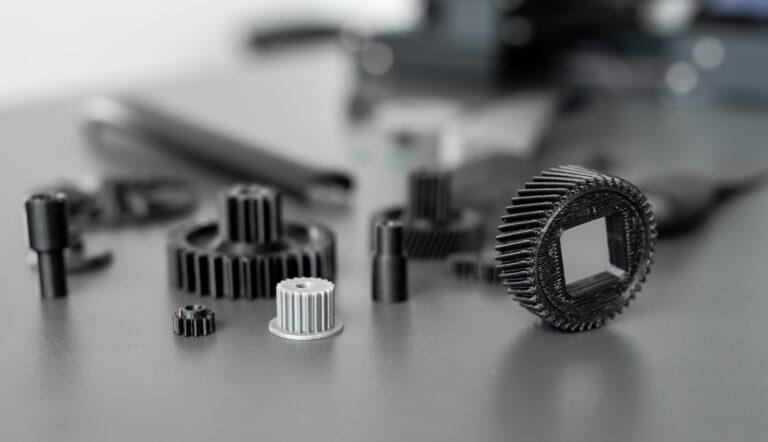

One of the main challenges in electric vehicle manufacturing is to reduce the weight of parts without compromising strength or functionality. With industrial 3D printing with Multi Jet Fusion, manufacturers have the ability to create lighter, more efficient and stronger components. The advanced 3D printing process with HP Multi Jet Fusion makes it possible to design parts with complex geometries that would not be possible using traditional manufacturing methods.

For example, structural parts, such as electric motor housings, battery mounts and other chassis parts, can be manufactured with extreme precision, which contributes to reducing the overall weight of the vehicle. This is essential for improving the range of electric vehicles, as a lighter vehicle consumes less energy and increases battery efficiency.

The ability of high-quality industrial 3D printing with MJF to create these customized parts at low cost and without long lead times represents a significant advantage over conventional automotive component manufacturing processes.

Rapid and customized prototyping with Multi Jet Fusion 3D

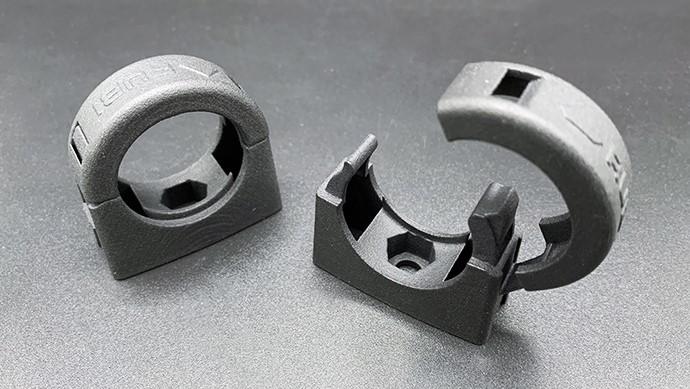

Prototyping is a critical aspect of developing new electric vehicle models. The ability to prototype with Multi Jet Fusion 3D allows engineers and designers to quickly experiment with new designs, test new materials and adjust components without the long lead times required by traditional manufacturing methods.

Advanced 3D printing with HP Multi Jet Fusion not only speeds up the prototyping process, but also enables greater component customization. This is especially important in the electric vehicle industry, where each car model may require a unique set of parts to suit specific battery, propulsion system or aerodynamic design characteristics.

By working with a leading 3D printing company that offers industrial 3D printing services, manufacturers can obtain high-quality prototypes in record time, reducing development time and production costs.

Accelerating production with high-quality industrial 3D printing

Thanks to industrial 3D printing services, electric vehicle manufacturers can bring their designs to production in much faster times than with traditional methods. HP MJF 3D printing offers excellent surface quality and precise detail on every part, making it an ideal choice for manufacturing functional and aesthetic electric vehicle parts. This level of precision is vital when it comes to critical components such as battery cooling systems, motor housings or suspension parts.

In addition, high-quality industrial 3D printing with MJF enables the creation of parts without the problems associated with mass production, such as defects or quality variations. This reduces the need for costly revisions and improves part consistency across all units produced. As a result, electric vehicle manufacturers can offer products with a higher level of quality, strengthening consumer confidence in these new models.

3D printing with HP Multi Jet Fusion is accelerating electric vehicle production by enabling manufacturers to create lighter, more efficient and customized components more quickly and cost-effectively. This technology not only improves quality and reduces production costs, but also optimizes prototype development and enables greater flexibility in electric vehicle customization.

By integrating 3D printing solutions for companies using advanced technologies such as Multi Jet Fusion, the electric vehicle industry is moving towards a more sustainable, efficient and high-performance future. Additive manufacturing will undoubtedly be one of the driving forces in the next generation of electric vehicles.

Multi Jet Fusion 3D printing at Proto&Go!

At Proto&Go!, as a leading 3D printing company, offers 3D printing solutions for companies looking to optimize their production process. With our industrial 3D printing services, we are ready to help companies transform their ideas into tangible realities, improving their competitiveness in a constantly evolving market.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!