In the world of rapid prototyping and custom parts manufacturing, properly defining dimensional tolerances is key to avoiding errors, rework, or incompatibilities during assembly. Although often overlooked in the early stages of 3D design, tolerances directly affect the viability of the prototype and the success of the final product.

In this article, we explain how to correctly calculate tolerances, taking into account the manufacturing technology used, and we give you practical guidelines to avoid last-minute surprises.

What are tolerances and why do they matter in prototyping?

Tolerances define the acceptable margin of variation in the dimensions of a part with respect to its theoretical value. In other words, they indicate how much a measurement can deviate without compromising the performance or assembly of the prototype.

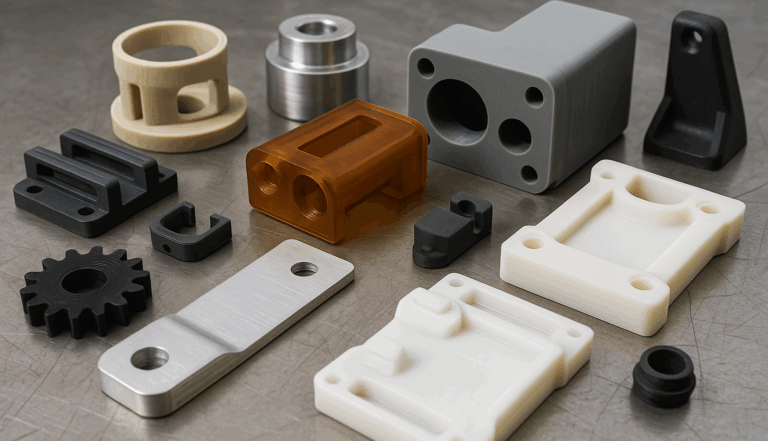

In both 3D printing and CNC machining projects, each technology has its own technical specifications, which must be considered from the outset of the design process.

A common mistake is to apply tolerances that are too tight, which do not add real value to the prototype’s performance but make manufacturing more expensive or cause errors. Conversely, tolerances that are too wide can cause slack, leaks, or assembly problems.

Tolerances in 3D printed parts

In 3D printing projects, tolerances depend on the technology and material. For example:

- FDM: typical tolerance of ±0.3 mm to ±0.5 mm in small parts, although it may vary more in large parts or uncalibrated printers.

- SLA or resins: high precision, typically around ±0.1 mm, and in some cases may be slightly lower for smaller geometries.

- MJF or SLS: good dimensional stability, with typical tolerances of ±0.2 mm to ±0.3 mm, although shrinkage may occur depending on the material and design.

For prototypes with parts that need to fit together, it is advisable to leave clearances of between 0.2 mm and 0.5 mm as a general reference, but always adjusting them to the size of the part, the geometry, and the material. In addition, 3D printing materials have different thermal shrinkage coefficients, which also influence the final result.

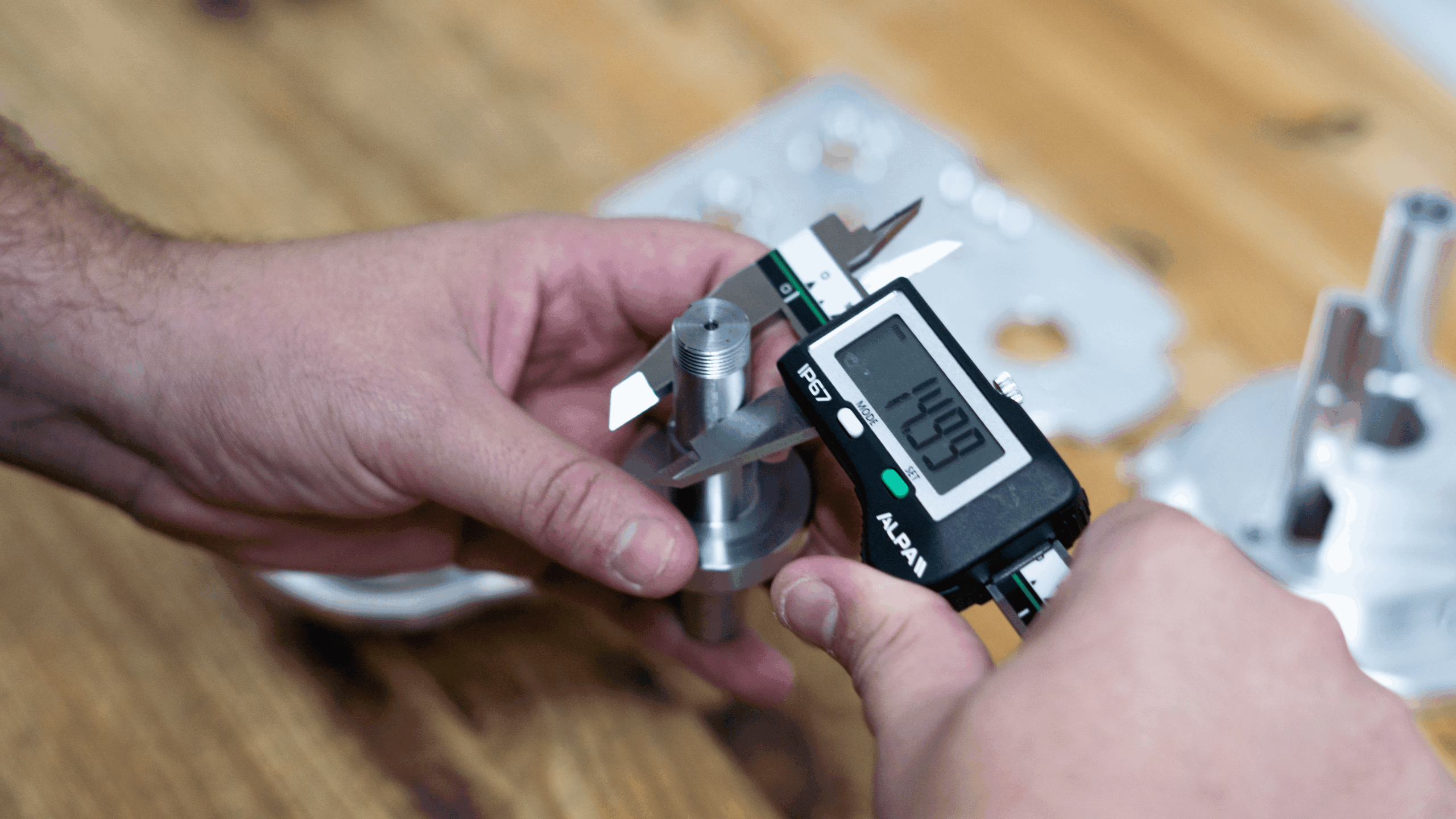

CNC machining tolerances

In CNC manufacturing , standard tolerances are around ±0.1 mm, although it is possible to achieve ±0.01 mm or even stricter values in high-precision processes under highly controlled conditions. The stricter the tolerances, the higher the cost and manufacturing time.

Therefore, it is important to assign tight tolerances only in critical areas, such as:

- Support or assembly surfaces.

- Holes for bearings or shafts.

- Connection with external components.

On the other hand, on non-functional surfaces, broader general tolerances can be used, optimizing time and costs.

Practical recommendations for designers, engineers, and startups

When you work on product development, each prototyping iteration is key to validating the design and moving smoothly on to the next phase. That’s why applying tolerances intelligently not only improves the final result, but also optimizes costs and manufacturing times:

- Apply general ISO tolerances when a specific adjustment is not essential. This will allow you to maintain dimensional control without unnecessarily increasing the cost of the process.

- Clearly identify and mark critical areas (assembly surfaces, bearing housings, or joints with external components) to apply tight tolerances only where it really matters.

- Leave sufficient margin for snap fasteners or clips. A well-defined clearance prevents assembly problems and improves the functionality of the prototype.

- Define clearances taking into account not only the type of joint, but also the scale of the part and the technology used.

- Consult your supplier whenever you have doubts about the actual capabilities of the technology or material. At Proto&Go!, our team reviews your 3D file and advises you on the achievable precision before manufacturing.

- Ensure that the 3D modeling and technical drawings are consistent. A clear and well-documented design minimizes the risk of misinterpretations and rework.

Proto&Go!: your online manufacturing partner

Incorporating tolerance criteria from the design stage is essential for any 3D printing or CNC machining project. It saves time and money and ensures that the prototype fulfills its function without the need for subsequent corrections.

At Proto&Go! , we offer 3D printing and industrial machining services that integrate professional finishes tailored to each objective. Upload your file, select the desired finish, and transform your idea into a tangible, functional reality that is ready for validation.

Upload your 3D file now and request a quote from our website!