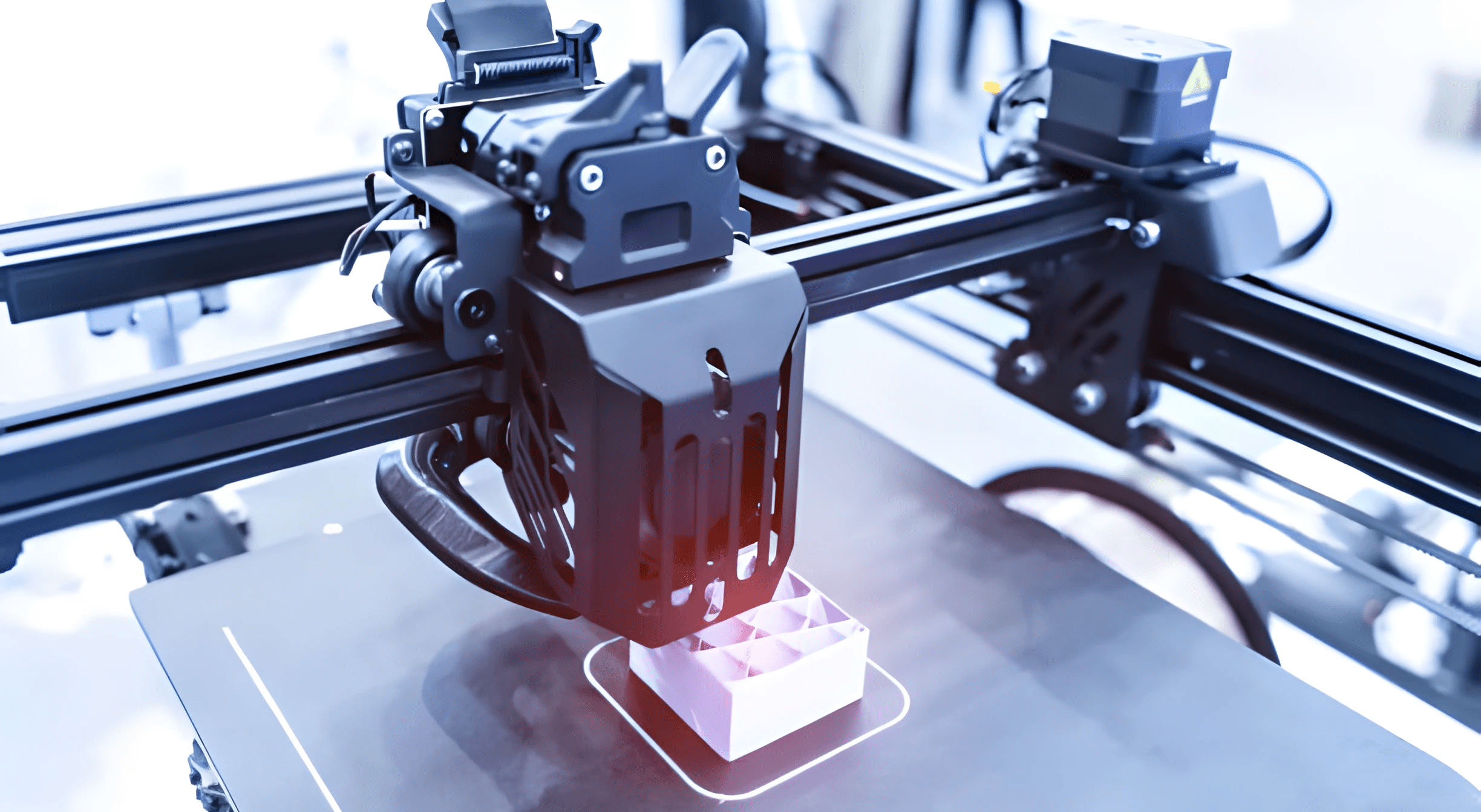

.3D printing has revolutionized a multitude of industries, enabling the creation of customized objects with unprecedented precision and efficiency.

In this article, we explore some of the applications of this technology and tell you about the latest innovations.

Customized medicine: Customized prostheses and implants

The ability to manufacture prostheses and implants tailored to the specific needs of individual patients has transformed modern medicine. A recent example is the development of 3D printed biodegradable breast implants for breast cancer survivors. Swedish startup Akira Science has created prostheses that degrade naturally in the body, offering a less invasive alternative to traditional implants.

In addition, 3D printing is used to create customized orthopedic insoles. Companies such as Led3D Group have developed systems that allow the manufacture of customized plantar orthoses using 3D scanners and 3D printers, improving precision and comfort for patients.

Construction: Sustainable and customized housing

The construction industry has embraced 3D printing to build homes more quickly and sustainably. This technology makes it possible to build complex structures with less material waste and reduced costs.

In September 2024, the exhibition “PRINT3D. Reprinting reality” at CaixaForum Lleida highlighted how 3D printing is revolutionizing construction, presenting cases of houses built using this technique.

Aeronautics: Efficient and lightweight components

The aerospace industry has found 3D printing to be an invaluable tool for manufacturing lighter and more efficient components. Companies like ITP Aero have succeeded in creating and certifying critical aircraft engine parts, such as the blades of the TP400, using selective laser melting techniques.

This methodology reduces the weight of aircraft and optimizes their performance, in addition to greatly reducing production costs.

Education and rapid prototyping: Facilitating learning and innovation

In education, 3D printing has become an essential tool to facilitate active learning. It allows students to materialize abstract concepts and develop practical skills in design and manufacturing.

In addition, rapid prototyping has accelerated innovation in multiple industries, enabling the creation and testing of functional models in reduced times, which drives the development of new products and solutions.

In conclusion, we can say that personalized 3D printing is transforming multiple sectors by offering solutions tailored to the specific needs of users and professionals. Its ability to produce complex objects efficiently and economically positions it as a key technology in the evolution towards a more innovative and personalized society.

Innovation in customized 3D printing at Proto&Go!

At Proto&Go! we specialize in HP’s Multi Jet Fusion (MJF) 3D printing technology, designed for industrial applications. This technique allows us to manufacture parts in different materials for 3D printing, such as Polyamide PA12, a rigid and resistant material, or TPA, a robust and flexible material.

Thanks to MJF, we have advanced from prototyping to the manufacture of industrial end-use items, allowing the rapid production of series of parts without the need for large investments in molds. At Proto&Go! we aim to provide the best 3D printing service for the development of your parts.

Don’t wait any longer and request your quote through our website!