Prototype validation has always been a crucial phase of product development. It is the moment when ideas become tangible and when the first real discoveries about compatibility, tolerances, and functionality emerge. However, it is also a stage where costly errors can arise: deformed parts, dimensional deviations, or assembly failures that delay the project. This is where artificial intelligence (AI) is beginning to completely transform the process.

In recent years, AI has gone from being an experimental technology to becoming a practical tool for engineers, designers, and development teams. Applied to quality control in prototyping, it allows defects to be detected automatically, variations to be analyzed, and ensures that each manufactured part meets expectations, whether through 3D printing, CNC machining, or other processes.

Why apply AI to quality control in prototypes?

Prototyping is a dynamic environment: geometries change, different versions are tested, and materials may vary during iterations. These factors make manual control slow and prone to errors. AI offers key advantages:

- Rapid defect detection: algorithms that recognize anomalies in a matter of seconds.

- Consistency: eliminates the subjectivity of manual inspection.

- Traceability: each prototype can be documented with images and associated data.

- Better decision-making: helps decide whether a part should be adjusted, reprinted, or re-machined.

These improvements have a direct impact on time, cost, and reliability, especially in projects where every iteration counts.

How does AI work in prototype inspection?

The most widely used techniques today are based on artificial vision combined with AI models trained to identify specific defects.

The usual flow includes:

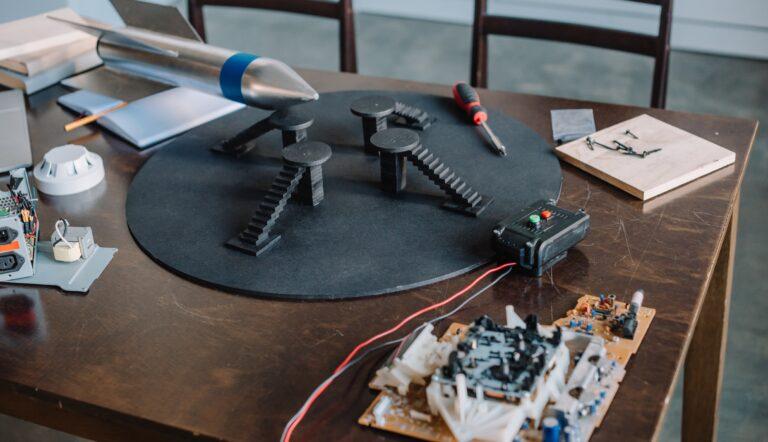

- Image capture: photographs, 3D scans, or images taken directly from 3D printing or CNC machines.

- Visual processing: algorithms detect irregularities in texture, color, or surface.

- Comparison with the original design: the 3D model or CAD file serves as a dimensional reference.

- Deviation detection: from inadequate tolerances to deformations or errors in the material.

- Automatic reporting: AI generates recommendations or validations that help decide the next steps.

Thanks to this approach, development teams can validate parts without having to inspect every detail manually.

Where does AI have the greatest impact on prototyping quality control?

AI is especially useful in these situations:

- 3D printed parts: detection of deformations, warping, adhesion failures, or layer inconsistencies.

- Machined components: automatic dimensional verification and comparison with CAD tolerances.

- Quick assemblies: identification of incompatibilities or assembly errors.

- Short runs or pre-series: check consistency without investing in complex industrial systems.

- Functional prototypes: validate resistance, deformation, or wear through repeated visual analysis.

In these scenarios, AI improves process reliability without requiring expensive equipment, making it ideal for startups and agile development teams.

AI and prototyping: a combination that accelerates development

The great value of AI is its ability to learn. With each iteration, algorithms can adapt, recognize new variations, and improve their accuracy. This makes prototyping an ideal environment for artificial intelligence: there is data, variations, and plenty of visual information to train models.

As models evolve, they enable you to reduce rework, validate designs in less time, increase the quality of each iteration, and identify patterns that the human eye might overlook.

AI does not replace designers or engineers: it empowers them, eliminating repetitive tasks so they can focus on decision-making and innovation.

Proto&Go!: your online manufacturing partner

At Proto&Go!, we work every day with 3D printing, CNC machining, and rapid manufacturing processes. We know how important it is to validate a prototype the first time around, without any surprises. That’s why we use advanced inspection tools that improve the final quality of the parts and allow us to detect errors before they impact your project.

Artificial intelligence applied to prototyping is not the future: it is a real tool that is already accelerating product development.

At Proto&Go!, we understand that every customer needs speed, clarity, and technical confidence. Our online prototyping platform allows you to easily upload your 3D files, select from technologies such as 3D printing, CNC machining, or silicone molding, and receive a quote in less than 24 hours.

Upload your file and receive your quote online now.