When developing a new product, every iteration counts. For startups and companies validating their design, the time between one version and the next can be the difference between reaching the market on time or falling behind. That’s where modular prototyping becomes a strategic ally: an approach that allows components to be adjusted, replaced, or evolved without having to redesign the entire assembly.

The idea is simple but powerful: design with change in mind. Create prototypes that can be modified quickly and efficiently as product development progresses, without reinvesting in molds, machining, or 3D files from scratch.

In this article, we explore what modular prototyping is, how to apply it to your designs, and what benefits it brings to startups, designers, and engineers.

What is modular prototyping?

Modular prototyping consists of developing a product divided into independent modules or sections that are easy to replace or modify without affecting the rest of the assembly. Instead of manufacturing a monolithic prototype, blocks are used that fit together using standard joints (threaded, snaps, clips, or couplings), which facilitates iteration.

This approach is inspired by the philosophy of modular engineering, widely used in sectors such as automotive and electronics, where each component is developed as part of a system but with functional independence. Applied to rapid prototyping, it allows designs to be adjusted, variants to be tested, or parts to be replaced with minimal cost and time.

For example, a startup developing an IoT device can iterate on the design of the outer body without modifying the electronic compartment, or change the fastening system without redoing the entire casing. This allows for faster progress and less investment.

Advantages of the modular approach to prototyping

- Faster and more economical iterations: By replacing only the modules that require changes, the cost and time of each version is drastically reduced. It is not necessary to manufacture the entire assembly for each test.

- Design flexibility: Allows you to explore different configurations or functionalities without compromising the rest of the prototype.. Ideal for startups that are still validating their value proposition or final product design.

- Natural evolution towards production

A modular prototype facilitates the transition to industrial production, as each module can evolve independently. This accelerates industrialization and improves the traceability of changes. - Better communication between design and engineering

By structuring the prototype into well-defined parts, collaboration between technical teams and designers is facilitated, avoiding assembly conflicts or errors in file versions.

How to design a modular prototype

Adopting this approach requires planning the 3D design from the outset. Some best practices include:

- Define clear interfaces between modules. Use standard fasteners (such as screws, magnets, or clips) to ensure compatibility between versions.

- Avoid unnecessary dependencies. Each module must be able to be modified or printed independently.

- Maintain reference dimensions. Ensure that mating areas have tolerances consistent with the technology used (FDM, SLA, CNC, etc.).

- Version CAD files by module. This simplifies change management and avoids confusion between revisions.

- Design for reassembly. Use systems that allow assembly and disassembly without damaging the parts.

The goal is to strike a balance between flexibility and robustness: the prototype should be stable enough to test, but also adaptable enough to evolve.

Technologies that facilitate modular prototyping

3D printing technologies (especially FDM and MJF) are ideal for developing modular prototypes due to their low cost and rapid iteration. They allow each module to be manufactured separately and tested for fit and tolerances in just a few hours.

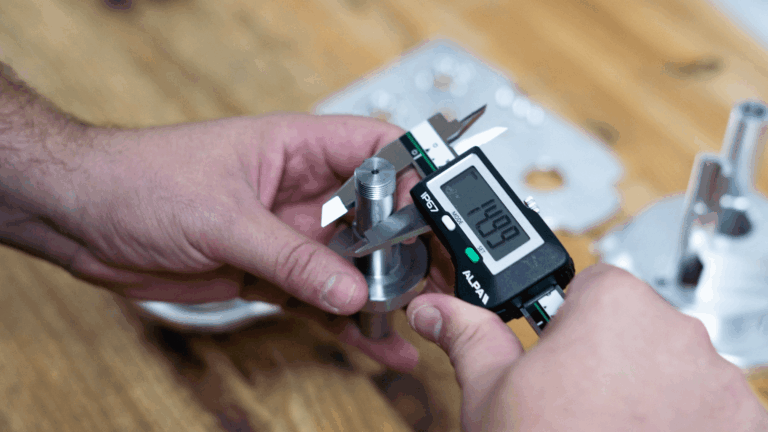

For its part, CNC machining offers greater dimensional accuracy and final materials that are more representative of actual production, making it an excellent option when the design is close to being validated for mass production.

A smart combination of both technologies can greatly speed up the process: 3D printing to validate geometries and moving on to CNC for parts that require high accuracy or strength.

In short, we can say that modular prototyping is an ideal methodology for startups, engineering firms, and development teams that rapidly evolve their product. It allows them to experiment, validate, and improve without redoing all the previous work, reducing costs and deadlines.

At Proto&Go!, we help our clients manufacture prototypes tailored to each stage of development, offering 3D printing, CNC machining, silicone molding, and professional finishes that make it possible to move from idea to product with agility and precision.

Ready to take your design to the next level? Upload your 3D file and receive your quote in less than 24 hours.