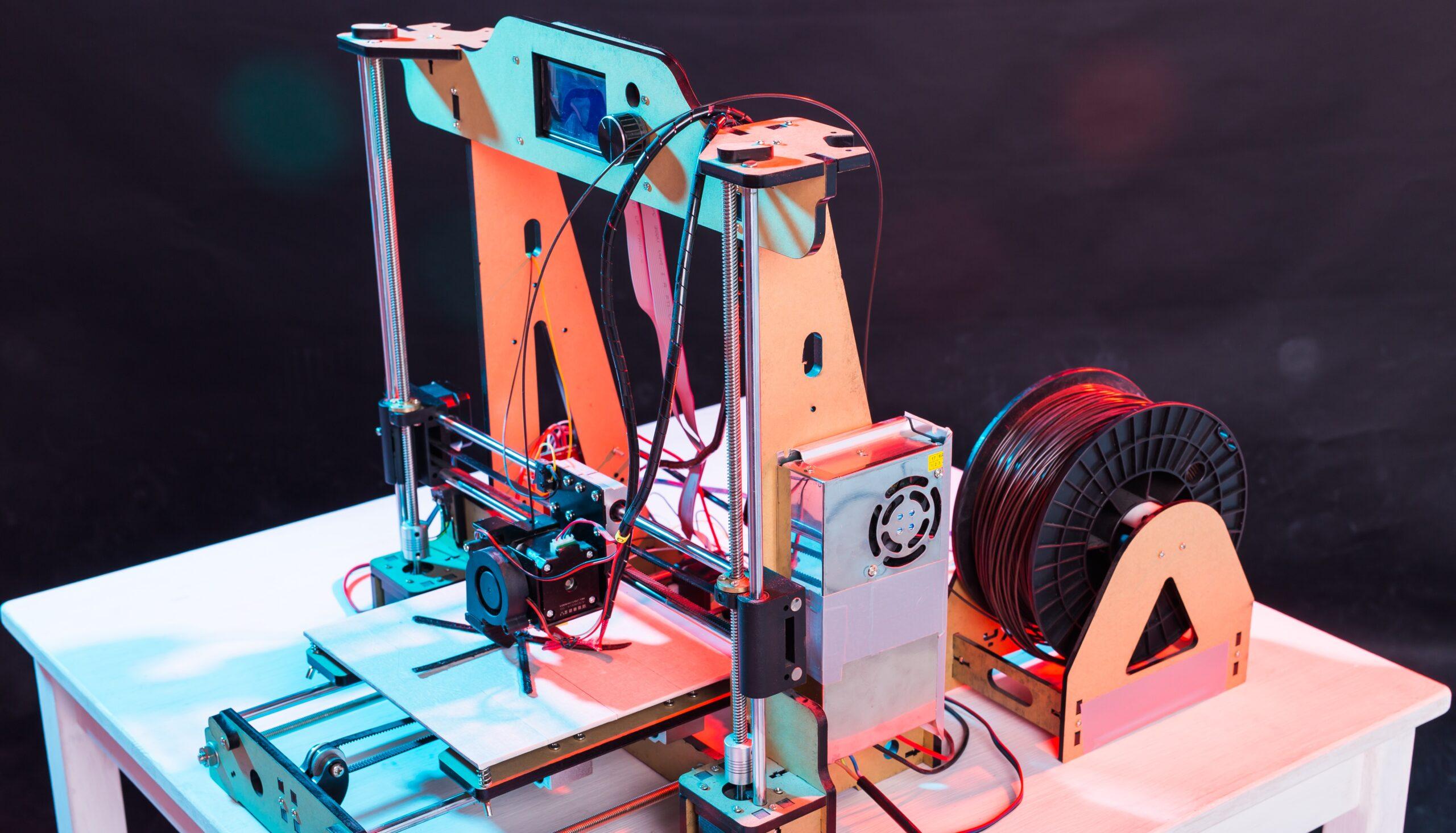

3D printers have changed the way we design and manufacture objects, enabling companies and hobbyists to realize their ideas with great precision. Thanks to additive manufacturing, it is possible to create complex parts with an impressive level of detail.

However, their performance is highly dependent on proper maintenance. Over time, problems such as nozzle blockages, calibration misalignments or mechanical component failures can affect print quality and lead to costly repairs. To avoid this, it is essential to implement a preventive maintenance routine that ensures optimal performance and prolongs the life of the equipment.

In this article, we explore best practices for taking care of your 3D printer and avoiding mishaps.

Cleaning and lubrication of key components

Dust, filament residues and dirt can affect the performance of a 3D printer. To avoid mechanical failures and ensure quality prints, regular cleaning is essential.

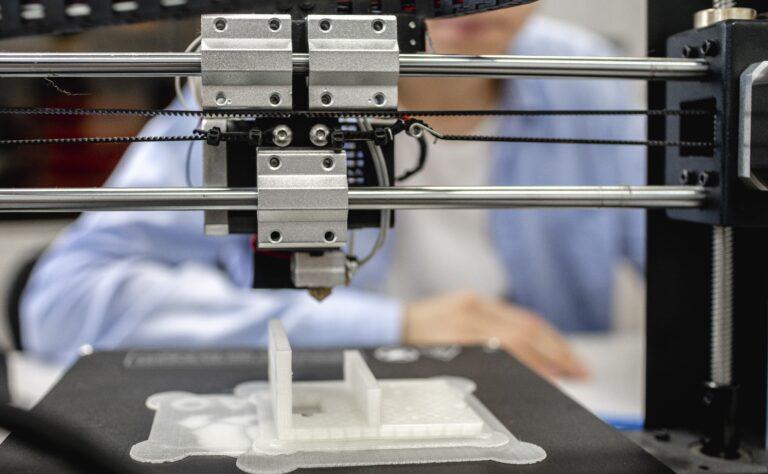

First of all, it is imperative to consider the nozzle, as it can become clogged with filament debris. It is recommended to do a regular cleaning with a special needle or use the “cold pull” method with nylon filament.

On the other hand, the surface must be cleaned after each printing to remove adhesive or filament residues, avoiding deformations in the first layer.

Finally, for linear guides and rods, applying suitable lubricants to the moving parts prevents wear and maintains smooth motion.

3D printer calibration and alignment

Accurate calibration is essential to avoid problems such as warping, layer displacement or poor filament adhesion. To do so, the following aspects should be checked:

- Leveling the bed: It is advisable to level the platform frequently, especially when changing media or transporting the printer.

- Belt tension: Drive belts should be tight, but not excessively tensioned, to ensure precise movements without vibration.

- Axis alignment: It must be verified that the X, Y and Z axes are correctly aligned to avoid printing errors.

Inspection of electronic components and firmware

The proper functioning of the electronics is key to avoid unexpected failures. Some preventive actions include:

- Check cables and connections: Ensure that there are no loose or deteriorated cables that could cause power failures or short circuits.

- Check the condition of the fans: The cooling fans of the extruder and the power supply must be clean and working properly.

- Update the firmware: 3D printing software updates can improve performance, fix bugs and add new functionality to the printer.

Proper use of materials and storage of 3D printing filaments

The type and quality of the filament directly influence the durability of the 3D printer components. To ensure proper use is essential:

- Choose quality filaments: Low quality 3D printing materials can cause impurities and blockages in the nozzle.

- Store filaments properly: Plastics such as PLA and ABS are sensitive to moisture, so they should be stored in airtight bags with silica gel.

- Adjust printing parameters: Correctly setting the temperature and speed according to the type of filament improves results and reduces extruder wear.

3D printing services as an alternative

For those who require parts with extreme precision or in large volumes, turning to specialized 3D printing services can be an efficient option. Rapid prototyping and additive manufacturing companies offer advanced solutions for designers, engineers and manufacturers, optimizing time and costs in the production of customized parts.

In addition, the industrial 3D printers used in these services allow working with a wide variety of 3D printing materials, from high-performance plastics to metals, offering solutions adapted to different sectors, such as automotive, medicine and architecture.

In short, we can say that implementing regular preventive maintenance on 3D printers not only minimizes the risk of failure, but also optimizes the quality of prints and prolongs the life of the equipment. By following these practices, common problems can be avoided and ensure efficient and long-lasting printer operation, whether in a home environment or in industrial 3D printers used for advanced production.

At Proto&Go! we specialize in HP’s Multi Jet Fusion (MJF) 3D printing technology, designed for industrial applications. This technique allows us to manufacture parts in different materials for 3D printing, such as Polyamide PA12, a rigid and resistant material, or TPA, a robust and flexible material.

Don’t wait any longer and request your quote through our website!