In the manufacture of 3D printed parts and prototypes, part deformation is one of the biggest problems that can arise in the process.

In this article we tell you everything you need to know about the deformation of 3D printed parts. In addition, you will also find effective strategies and techniques to prevent or correct this error in the 3D printing process.

What is warping?

The term warping can be defined as deforming or bending, therefore, it is the term used when the first layer of a part deforms and detaches from the printing surface.

Deformation usually occurs in large or long parts, since it is in these types of parts where the thermal stresses in the part become more powerful and end up detaching the corners.

What are the causes of deformation in 3D printing?

Deformation of 3D printed parts is a common problem in this technology, and can be caused by several factors. Some of the most common causes are:

- The level of the base: if the base is not level, the print is more likely to warp as the plastic cools.

- The temperature of the bed: if the bed is too cold, it can cause the plastic to cool too quickly and thus deform.

- The geometry of the print: parts with complex geometries are usually more prone to deformation, as they have more points of contact with the bed, i.e. more areas prone to cooling and shrinking.

- The printing material: it is important to take into account that some materials are more prone to deformation than others (e.g. ABS).

Solutions for deformation in 3D printing

As we have discussed, although warpage in 3D printed parts can be a serious problem in the 3D printing process, there are ways to prevent it and to fix it. The following are some examples:

Temperature regulation

One way to avoid warping is to regulate the temperature of both the printer and its environment. Several methods are available for this purpose:

First, it is possible to adjust the cooling, as most current 3D printers have a part cooling fan that helps to cool the material while printing. It is essential to adjust both the speed and direction of the fan to help control the rate at which the material cools.

Another simple way for temperature regulation is the use of a heated building plate. In this way, the material can be prevented from cooling and shrinking too quickly. At this point, it is important to note that in order to use a heated build plate, it is necessary to have a printer with a base capable of heating.

The cutter configuration

Another optimal solution to avoid warping in 3D printed parts is to print more slowly, as this gives the material more time to cool and solidify before adding the next layer. This is a particularly useful technique for materials prone to deformation.

For this, only the print speed setting in the 3D printer software needs to be adjusted.

Even so, it is important to keep in mind that the optimum speed will depend on the material used and the complexity of the printed part.

Adherence to the bed

Adhesion to the bed is a key aspect to avoid deformations during the 3D printing process. Using a suitable adhesive will help ensure that the part remains bonded while cooling and therefore reduce potential warping problems.

Adding borders

If after trying all of the above options your parts continue to curl or warp, another possible solution is to add a border to your prints. This will help keep the edges of the piece attached, as they are usually only a few layers high.

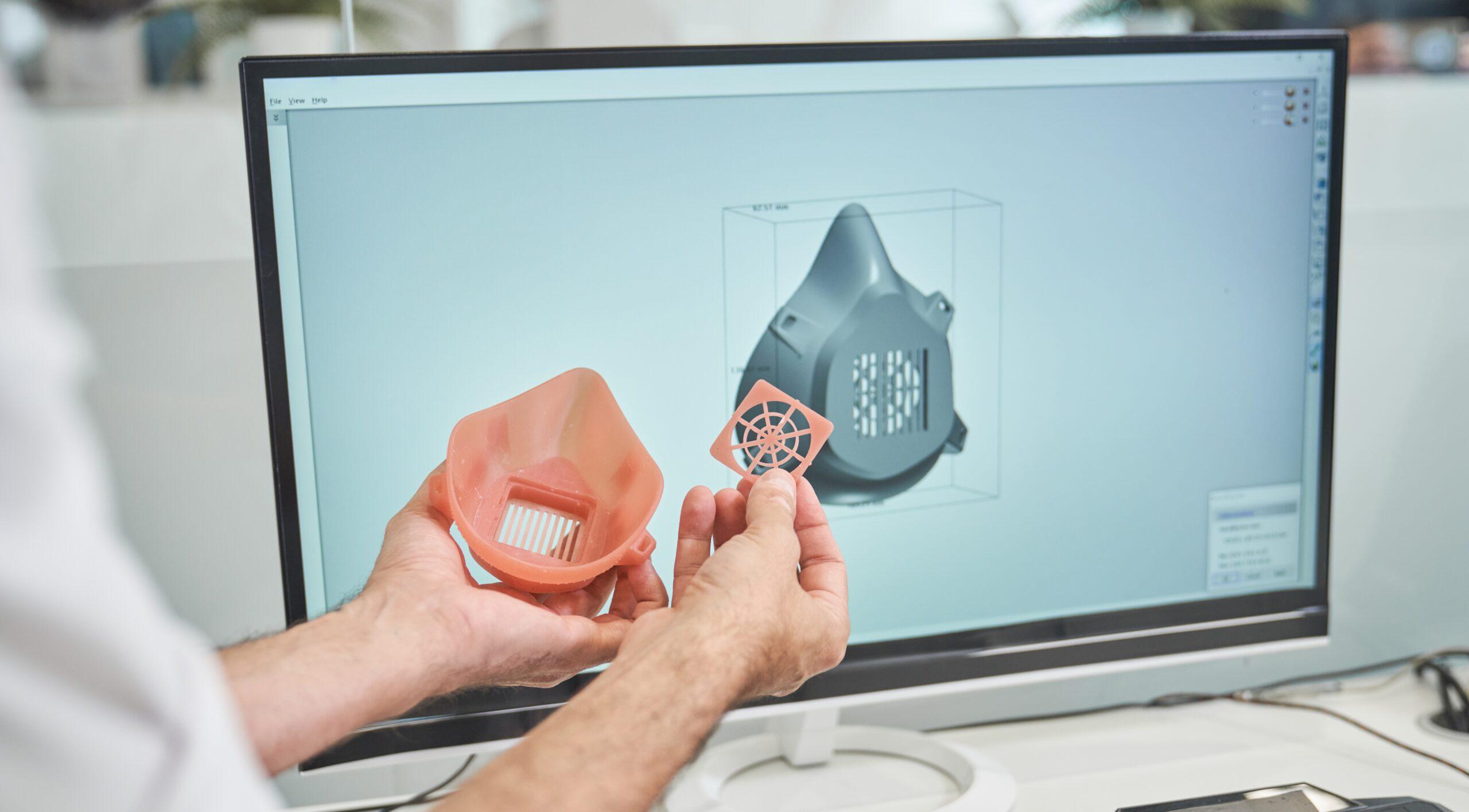

At Proto&Go! we provide the best service for the development of your parts and prototypes through additive manufacturing. Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!