In little more than a decade, 3D printers have gone from being a technological curiosity reserved for makers and enthusiasts to become an indispensable tool for designers, educators, entrepreneurs and creative minds. This evolution has been marked by the democratization of the technology, the improvement of print quality and the emergence of a global community that drives innovation from the bottom up.

In this article, we explore how 3D printers have evolved from rudimentary and experimental tools to mature technological solutions, adapted to different uses and levels of expertise. We analyze their technological milestones, the role of the community in their development and their growing application in practical contexts that go far beyond leisure.

From the first kits to plug-and-play printers

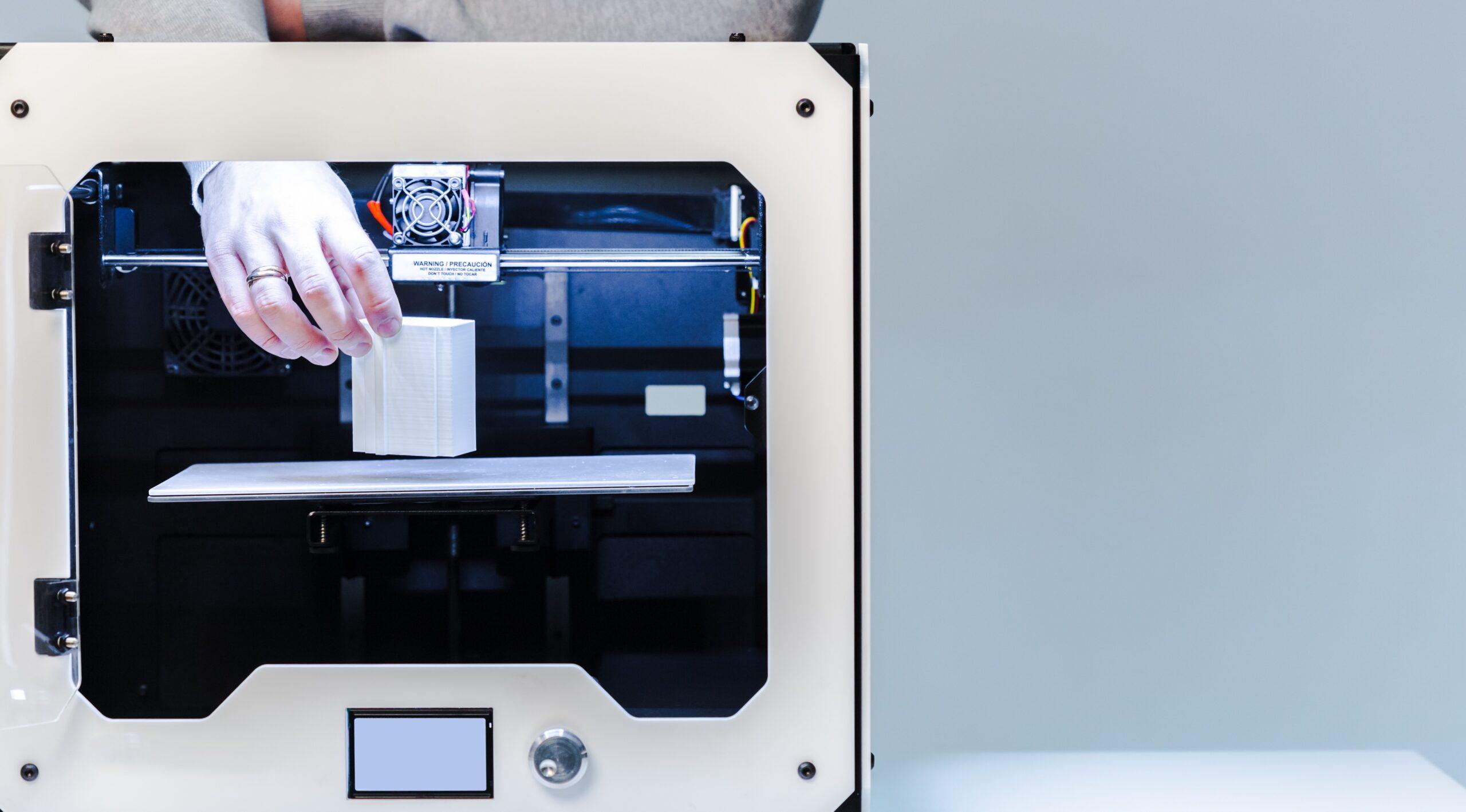

The first models accessible to the general public appeared around 2010, with projects such as RepRap, which allowed users to assemble their own printers from scratch. These open and fully customizable machines required some technical knowledge and a fair amount of patience, but they laid the groundwork for a revolution.

Over time, manufacturers such as Prusa, Creality or Anycubic began to launch more user-friendly models, with simplified assembly, automatic calibration and a user experience more similar to that of a traditional paper printer. This opened the door to thousands of users who wanted to experiment without any knowledge of electronics or programming.

One of the biggest drivers of the growth of 3D printing has been its community. Platforms such as Thingiverse, Printables or Cults3D have facilitated the sharing of millions of free designs, allowing anyone to download and manufacture useful, decorative or experimental objects from home.

Forums, Reddit groups and specialized YouTube channels have helped users solve common problems, improve the quality of their prints and learn new techniques. Thanks to this decentralized collaboration, the technology has evolved rapidly, incorporating constant improvements in both hardware and software.

Beyond Entertainment: Practical Applications of 3D Printing

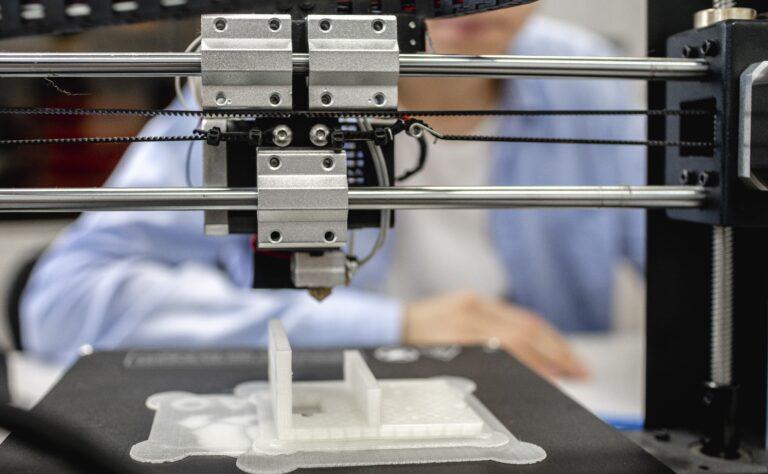

While printing figurines, game pieces or decorative accessories is still very popular, more and more people are using their 3D printers to create real solutions to everyday problems. From spare parts for household appliances to customized organizers, the 3D printer has become a practical and cost-effective resource.

In education, many schools and training centers have incorporated 3D printing as a tool to teach design, mathematics, physics or technology in a tangible way. For small entrepreneurs, the possibility of creating prototypes or short series without the need for large investments has opened up new business opportunities.

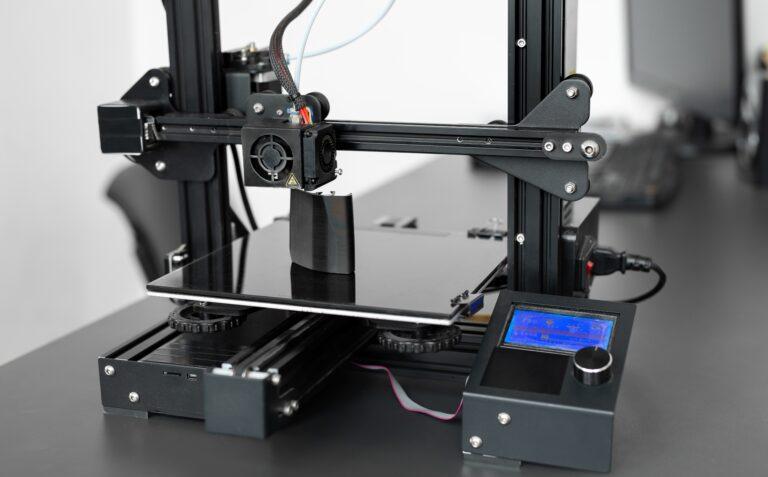

The future of 3D printing: smarter printers and advanced materials

The current trend is towards increasingly intelligent home 3D printers: connected to the cloud, with remote control from cell phones, integrated cameras and real-time error detection. In addition, the variety of materials available has multiplied, with filaments that mimic wood, metal, carbon or even flexible and recycled materials.

The combination of these improvements will make 3D printers even more versatile, accurate and easy to use, establishing them as an essential tool in the digital home of the future.

In short, home 3D printing is no longer just a hobby: it is a way to empower users, encourage creativity and provide a quick and personalized response to everyday needs.

At Proto&Go! we specialize in HP’s Multi Jet Fusion (MJF) 3D printing technology, designed for industrial applications. This technique allows us to manufacture parts in different materials for 3D printing, such as Polyamide PA12, a rigid and resistant material, or TPA, a robust and flexible material.

Don’t wait any longer and request your quote through our website!