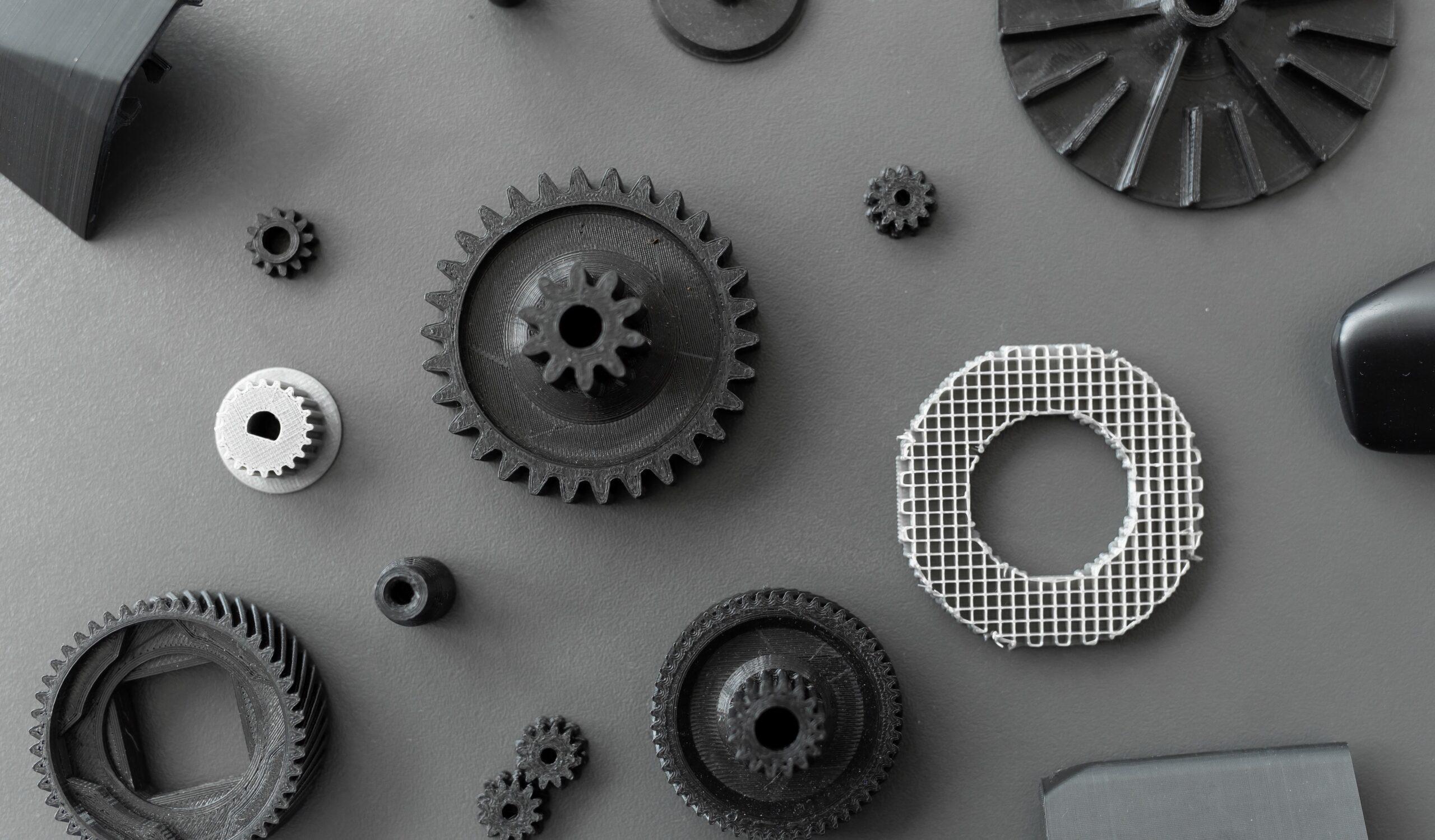

One of the most common myths about 3D printing is that parts produced with this technology are fragile and prone to breakage. This statement is totally incorrect.

3D printed parts can become as strong as parts made of plastic or metal materials. Those parts that turn out to be fragile or not so resistant are caused by a poor choice of materials or technologies and bad decisions in the 3D design process of the part.

In this article we tell you three tips to make 3D printed parts more resistant:

The choice of material for 3D printed parts

First of all, one of the most obvious factors, but also the one that most affects the strength of 3D printed parts, is the choice of the ideal material for each project and application.. It is essential to use materials with robust mechanical properties. On the other hand, some materials can be difficult to print on low-cost 3D machines due to the high temperatures required.

At Proto&Go! we use PA12 and TPA 90A, two materials with great strength and durability. On the one hand, parts made of PA12 have high chemical resistance, density and lower porosity, while parts made of TPA have properties such as flexibility and toughness.

The importance of design in the performance of the parts

Once the limitations and advantages of each material in terms of strength have been analyzed, it is important to bear in mind that the 3D model must be optimized for the manufacture of the part. That is, a part designed for CNC machining will behave very differently in additive manufacturing, so it could generate a brittle part.

For the manufacture of robust 3D parts, it is important to consider the following factors during the 3D printing process:

- Create support walls to help maintain long vertical structures where possible

- Respect the minimum thicknesses of the technology

- Include radii between flat parts and their vertical walls

Nowadays, there are some softwares that allow you to improve a 3D model automatically, and even optimize its geometry. It is an excellent tool for optimizing the strength and, above all, the cost of 3D printed parts.

On the other hand, there are also simulation softwares, with which it is possible to study the mechanical behavior of parts by simulating the manufacturing process in 3D and the mechanical strength of the part.

Post-processing

The surfaces of 3D printed parts contain stress concentrators, which can lead to early failures.

Post-processing, i.e., filling, sanding and chemical smoothing, can smooth these surfaces and thus improve part performance. Therefore, surface finish improvements are a critical part of the design process.

In short, we can say that the success of the strength of a 3D printed part lies in the manufacturing process and the selection of materials.

At Proto&Go! we offer the best service for the development of your parts and prototypes through additive manufacturing. Our specialty is Multi Jet Fusion (MJF) printing, a technology that makes it possible to manufacture series of parts in very short production times and without the need for high investments in molds.

What are you waiting for? Request your quote now through our website!