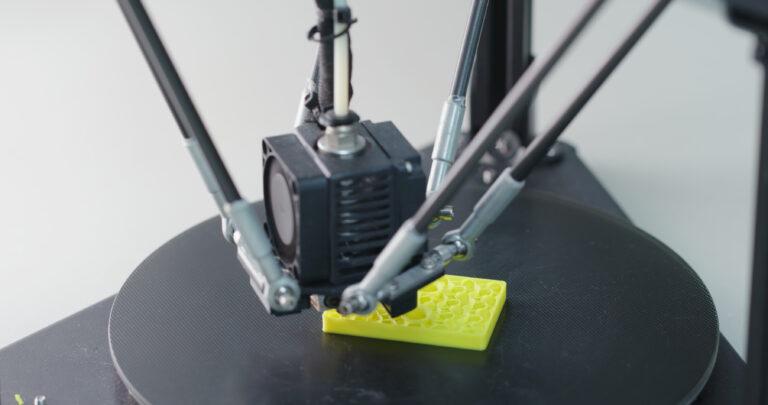

3D printing is one of the most popular technologies at the moment. Every day we talk about its evolution, about the aspects and sectors that this technology is revolutionizing and, above all, about its future.

What is impressive about additive manufacturing is its transversality. A large number of companies from different sectors have already started to use it: from the health sector to the food and automotive industries.

On the other hand, its great advantage is the customization of the products to the specific taste of each consumer.

Advances in 3D printing

To understand the future of 3D printing it is necessary to analyze some of the most relevant advances made by this technology in recent years:

- The first 3D printed aircraft has been designed and planned at the University of Southampton.

- A prosthetic hand has been built for a child using 3D printing in Madrid.

- Local Motors has unveiled a 3D printed car.

- In 2012, the first prosthetic implant of a 3D printed jaw was performed.

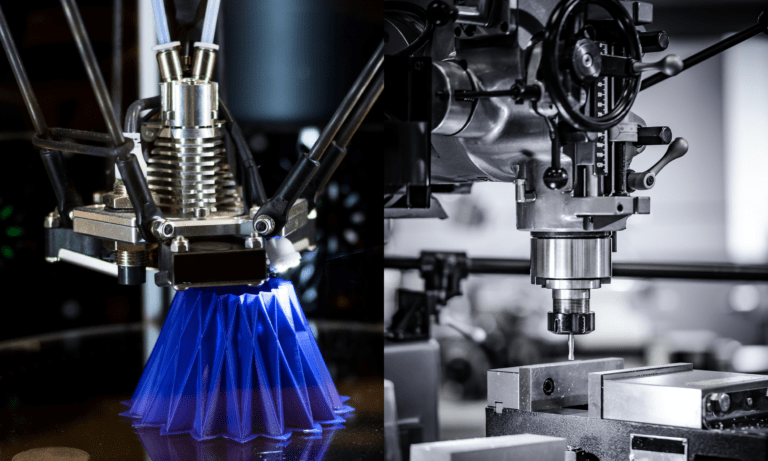

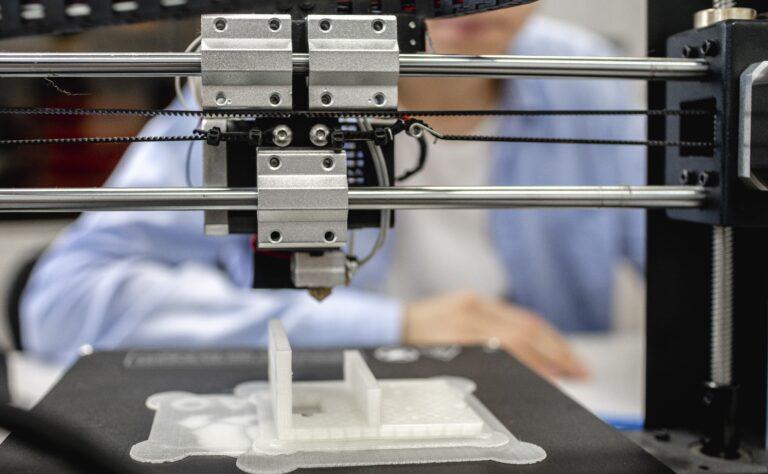

On the other hand, in the industrial sector, more specifically in the manufacturing and design of parts and prototypes, 3D printing has also undergone an immense evolution.

First, with respect to materials, a wide range of printable materials have been developed and diversified, including advanced plastics, metals, ceramics and composites. This factor has greatly expanded the possibilities for the design and manufacture of parts with specific properties.

Second, advanced 3D printers allow the printing of parts with multiple materials or colors in a single run.

Another important change was the development of 3D printers capable of building large-scale parts and prototypes, relevant for applications such as construction and in the manufacture of larger components.

Finally, another area where 3D printing has experienced a breakthrough is in sustainability. In recent years, the company has been working on the research and development of more sustainable materials for 3D printing, as well as on the optimization of processes and techniques to reduce waste.

Where is additive manufacturing headed?

Some experts say that 3D printing is the backbone of the fourth industrial revolution and, for this reason, the main forecasts point to the trend that the 3D printing market will triple in the next few years.

However, we cannot even begin to imagine the advances that can be made thanks to this technology and the fourth industrial revolution. Some trends point to a future with ideas such as the following:

In the healthcare sector, we will be able to see unimaginable advances. For example, in the field of orthopedics, it will be possible to generate parts that are perfectly adapted to each patient. The possibility of generating implants and organs at the surgeon’s disposal in an operation is even being considered. The challenge lies in the creation of biocompatible materials, on which research is already underway.

On the other hand, in the construction sector, 3D printing will be used to manufacture habitable structures, which could even be used in space.

In the robotics sector, we will also see impressive advances. MIT(Massachusetts Institute of Technology), for example, is working on a project aimed at creating robots that can self-replicate and self-repair.

In short, 3D printing promises to continue to solve complex problems in industries at different scales. This manufacturing method will continue to evolve and add versatility and efficiency in many different ways.

At Proto&Go! we are specialized in MJF (Multi Jet Fusion) printing and we aim to provide the best 3D printing service for the development of your parts.

What are you waiting for? Request your quotation now and receive your quote in less than 24 hours!