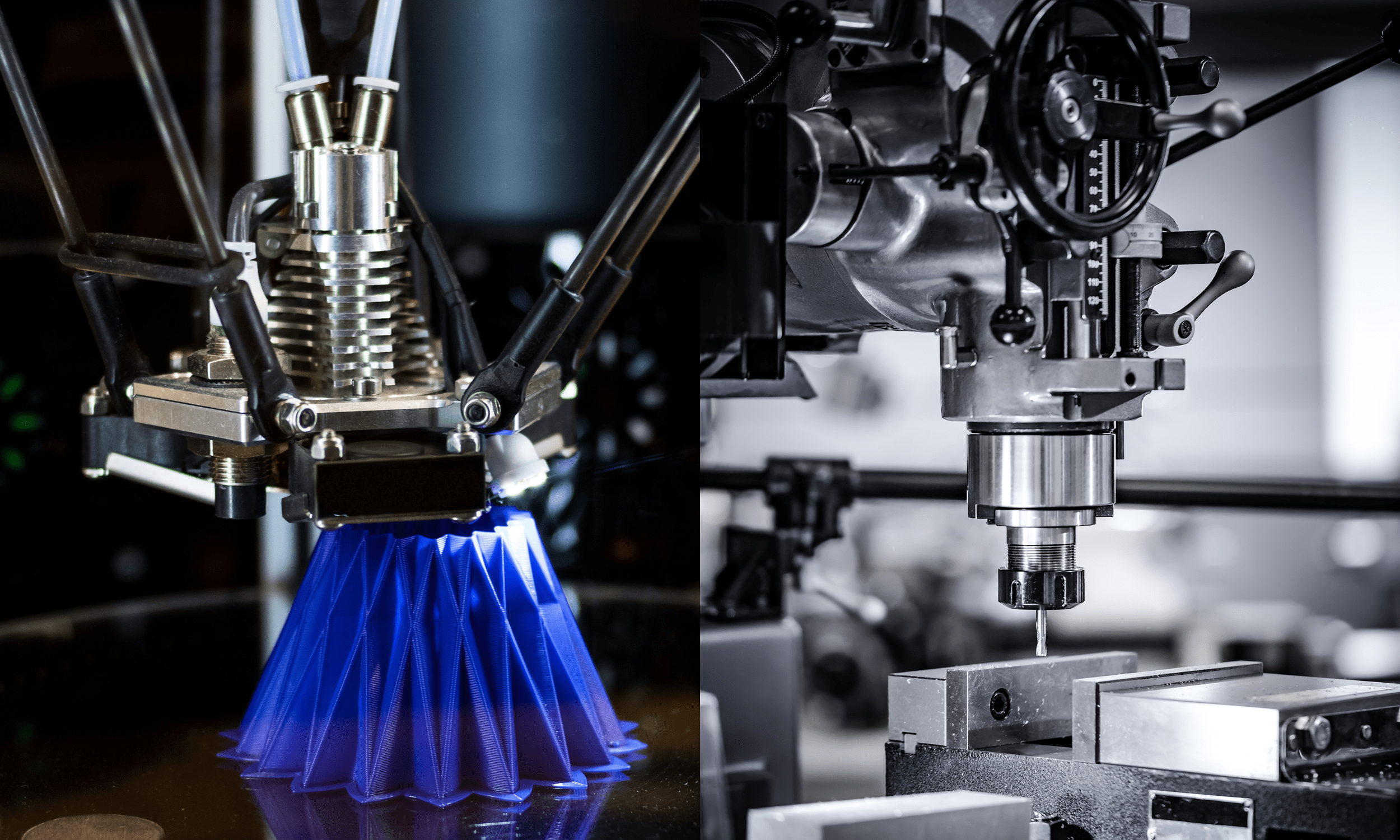

In the area of parts and prototyping manufacturing, technology has provided engineers and designers with a variety of tools to take their ideas from concept to reality. Two of the most important methodologies in this field are 3D printing and CNC machining.

Both offer unique advantages in terms of speed, accuracy and versatility, but knowing when to transition from one technology to the other can be crucial to the success of a project.

It is normal for questions such as the following to arise: When do I use each technology? When is the right time to take this step? What are the factors to consider before making the transition?

In this article, we will explore the key signals that indicate when it is appropriate to make the switch from 3D printing to CNC machining, as well as the benefits and challenges associated with each technology and this transition.

CNC Machining: When to use it?

Manufacturing by CNC machining represents a conventional approach to producing parts by the gradual removal of material from a starting block.

When comparing the creation of parts and prototypes using CNC machining with 3D printing, both methodologies have distinct advantages. While CNC machining requires more time to produce a part compared to 3D printing, it often offers superior quality and finish in final production.

This technology can be an excellent option for the production of prototypes. It is true that one-off prototypes can be quite costly, but huge savings can be made by making large quantities.

The best applications for CNC machining are:

- Intermediate stage prototyping

- Production models

- Ideal volume: more than 3 units

3D Printing: When to use it?

3D printing continues to transform hardware development by providing both individuals and enterprise teams with access to rapid and affordable prototypes.

With this technology, companies can print designs daily at a fraction of the cost of other prototyping methods.

In addition, the capacity constraints for part manufacturing are much lower compared to CNC machining, allowing teams to focus solely on quickly translating digital concepts into physical models, even as the design continues to evolve.

The best uses for 3D printing are:

- Early stage prototyping

- Pre-manufacturing prototyping

- Ideal volume: 1 to 5 units (larger quantities can be costly)

When to switch from 3D printing to CNC machining?

There is no official rule that determines the exact time to start the transition from 3D printing to CNC machining. In fact, in many instances, product manufacturing can benefit from both methods.

A clear example is aerospace companies. In this case, high-strength prototypes are required. Therefore, they usually make a rapid prototype in 3D printing to verify the size and shape and then reproduce the same part by CNC machining.

However, in most situations, the level of maturity or development of your design can be taken into account as an indicator to move from 3D printing to machining of parts, in order to achieve functionality and durability more in line with production materials.

In short, if your design is advanced enough that you are comfortable producing larger quantities or if 3D parts are not robust enough for the functional needs of your project; it may be time to consider making the transition.

At Proto&Go! we have a team of highly qualified experts that will help you and offer you the best service for the development of your parts and prototypes, both through 3D printing and CNC machining.

What are you waiting for? Contact us or request your quote online.