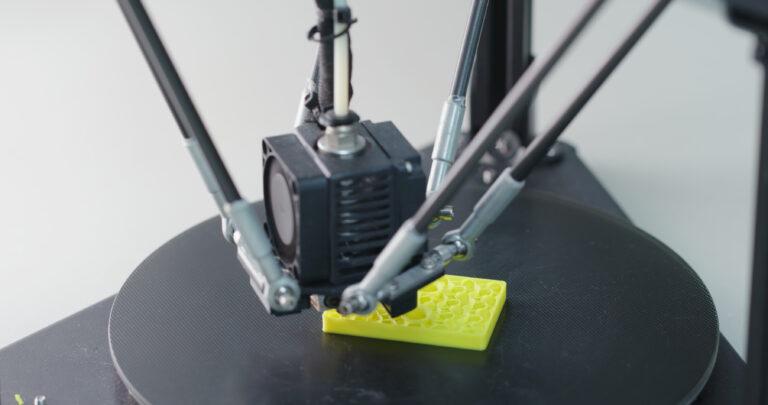

3D printing has revolutionized the way we manufacture products, not only because of its ability to create customized parts quickly and accurately, but also because of its potential to make production more sustainable.

In a world where waste reduction is a priority, additive manufacturing offers an efficient alternative that minimizes material waste compared to traditional methods.

In this article, we will explore how 3D printing is transforming industry, reducing environmental impact and positioning itself as a key tool for a more sustainable future in the industrial sector.

Reduction of production waste

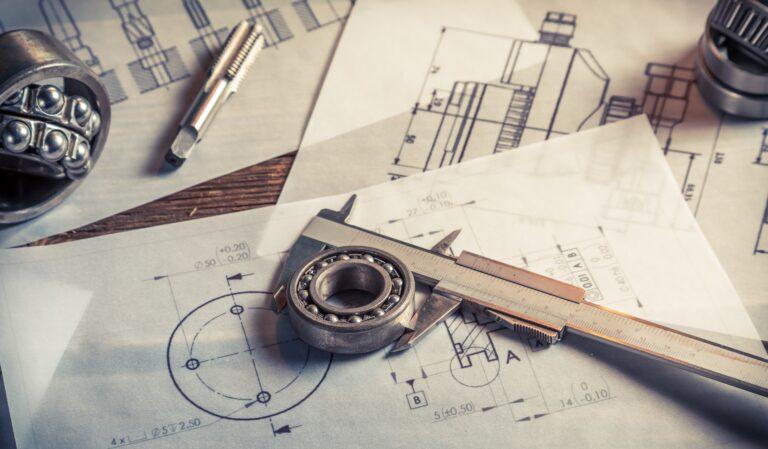

When it comes to sustainability, one of the great benefits of 3D printing is its ability to minimize waste during production. In traditional manufacturing processes such as CNC machining, large amounts of waste are generated. In contrast, in 3D printing, by building objects layer by layer, an exact amount of material is used.

The use of recycled and sustainable materials in 3D printing

Additive manufacturing currently offers some sustainable or recyclable materials made from renewable raw materials such as PA11. In addition, more and more innovative materials are being used that reduce the ecological footprint and act as substitutes for traditional materials such as metals or plastics.

Still, generating sustainable manufacturing materials remains one of the most complex challenges. Research into new materials that are strong and have end-part mechanical properties remains a crucial factor in the success of 3D printed part manufacturing.

On the other hand, it is important to note that there are already advanced 3D printers that are designed to work with recycled materials.

Energy efficiency in the 3D part printing process

Another key aspect of 3D printing’s sustainability is its energy efficiency. Unlike traditional methods, which often require large amounts of energy to operate heavy machinery or perform multiple manufacturing processes, 3D printing reduces energy consumption by consolidating several stages into a single process.

In addition, many 3D printers use less energy by operating in a more precise and controlled manner, which contributes to a lower environmental impact.

On the other hand, additive manufacturing technologies also enable localized production, which means that products can be manufactured closer to where they are needed, significantly reducing emissions from transportation and logistics. This ability to produce locally and on demand not only optimizes the supply chain, but also helps reduce energy use in distribution, strengthening the commitment to sustainability.

In short, we can say that 3D printing has not only transformed the way we produce parts and prototypes, but has also opened the door to more environmentally friendly manufacturing. From waste reduction and the use of recycled materials to improved energy efficiency, this technology is emerging as one of the keys to progress and evolve towards a more sustainable industrial model.

At ProtoandGo! we provide the best service for the development of your parts and prototypes through additive manufacturing. In addition, we specialize in printing using Multi Jet Fusion or MJF, the latest HP technology designed especially for industrial applications.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!