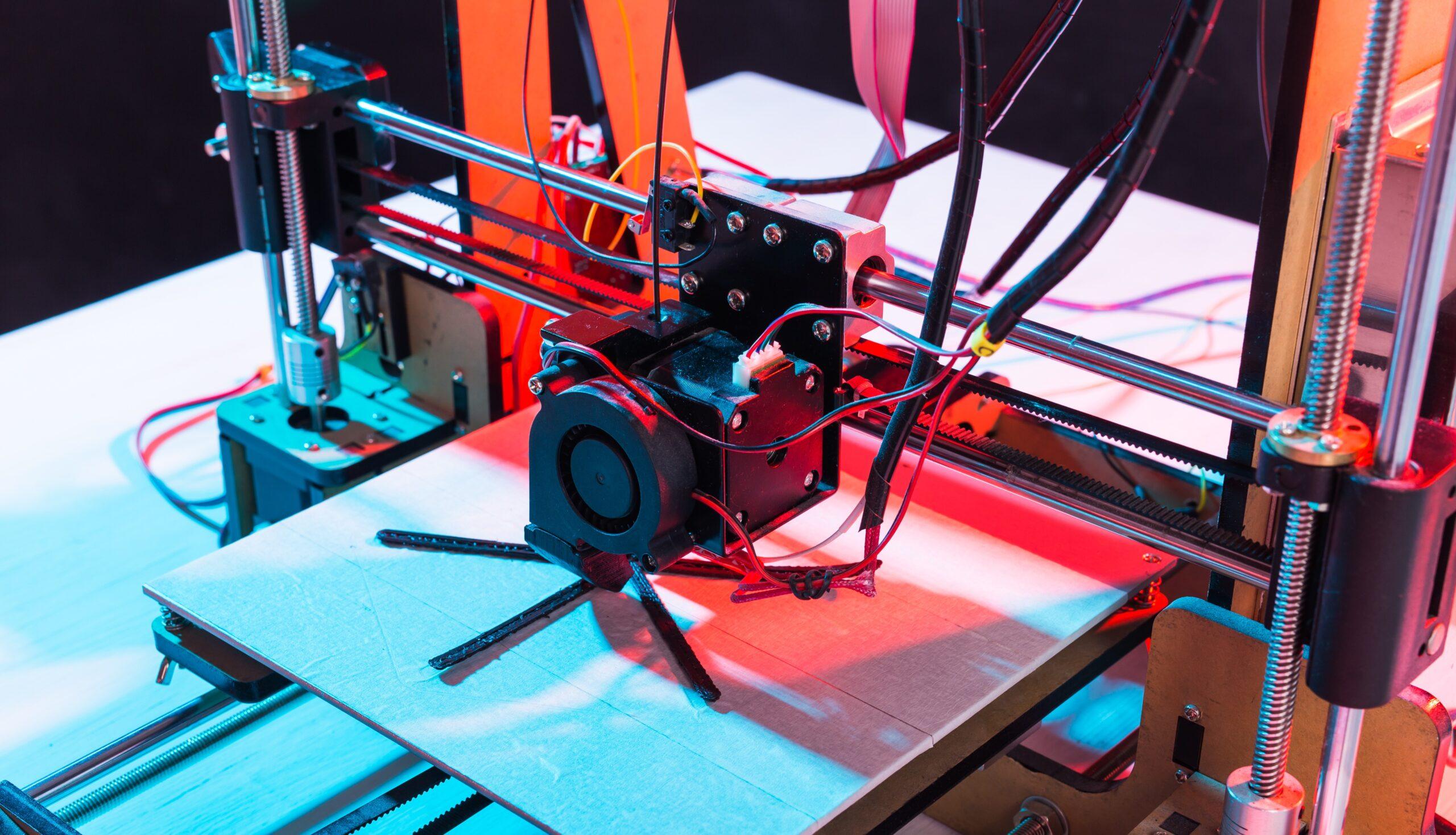

One of the things we are concerned about when 3D printing is optimizing the speed of the 3D printer. To do this, several factors must be taken into account, such as the type of 3D printer, its mechanics or the motors that control the X and Y axes, among others.

First of all, it is essential to take into consideration the maximum volumetric speed, i.e. to adjust the maximum amount of filament that the extruder will have to push through the melter.

The speed of the printer can also be affected by the filament chosen (the choice of brand or material for 3D printed parts).

Finally, it is important to take into account other factors such as shrinkage speed, displacement, filling and layer height or the use of nozzles and the right extruder.

Three tips for stronger 3D printed parts

Choosing the optimal 3D printing design tips regarding the direction of layers or the material of 3D printed parts can make all the difference and ensure the best quality for parts and prototypes.

There are different design optimization methods that are able to guarantee durability and the most efficient use of the material. Some of the factors that should be taken into account are:

- The direction of the 3D printed layers: this is one of the major considerations for the durability of the parts.

- The density of the 3D printing material

- The choice of the most resistant material for your application

Strategies to reduce the cost of the 3D printing process

Although 3D printing technology offers numerous advantages, one of the main concerns when using this manufacturing process is its cost. Still, from design to manufacturing, there are some methods that can have a significant impact on costs.

With regard to design, one way to reduce costs is to hollow out the 3D model, i.e. to remove the inner material of the part. In this way, in addition to using less material and, therefore, reducing its cost, it is also an ideal option for achieving a lightweight piece.

On the other hand, it is also possible to reduce costs by selecting the right manufacturing options. This includes: the material, the process, the production volume, the finishing process…

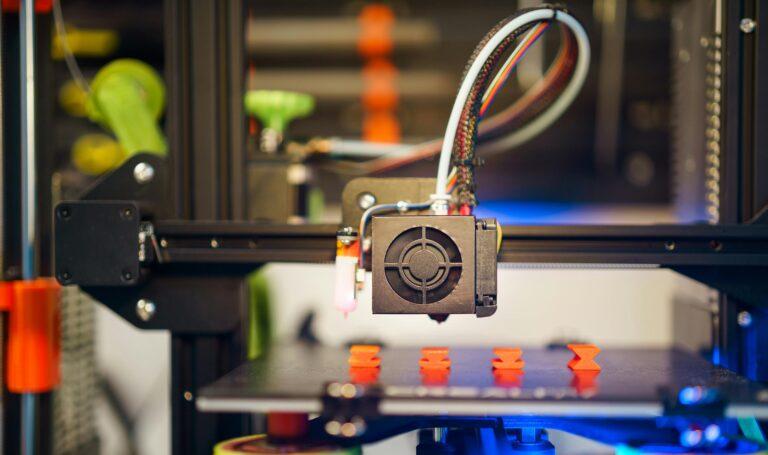

The 3D printing revolution in the home

. 3D printing technology is no longer exclusive to industry, but is now entering the home. Today, having a 3D printer at home offers a wide range of both creative and functional applications.

Undoubtedly, its main advantage is the creation and customization of unique objects for your environment. From home decor items to toys or exclusive figurines, among many other possibilities.

In short, we can say that a home 3D printer is not only a DIY tool, but it offers great benefits of customization, creativity and functionality.

Therefore, optimizing the 3D printing process is essential for the efficiency of your projects and to achieve significant time and cost savings.

At Proto&Go! we provide the best service for the development of your parts and prototypes through additive manufacturing. We specialize in printing by Multi Jet Fusion or MJF, a technology that makes it possible to manufacture series of parts in very short production times and without the need for high investments in molds.

Request your quote now through our website!