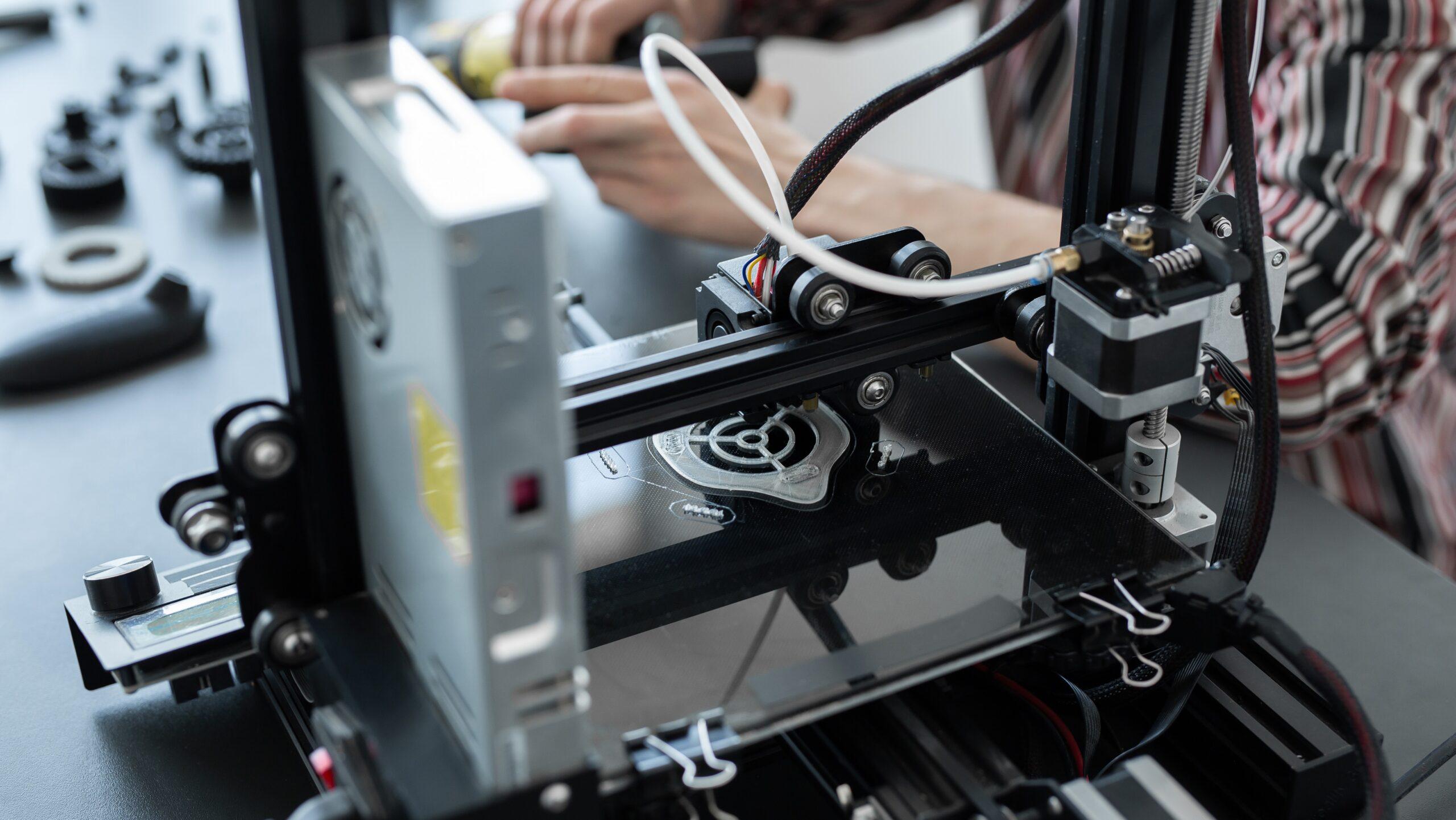

3D printing is one of the biggest trends of recent years in the technology sector and is constantly evolving and improving. There are three main 3D printing technologies: FDM, SLA and SLS.

- Fused Deposition Modeling (FDM) is one of the most popular 3D printing technologies because of its relative simplicity, accessibility and low cost. It is typically used in rapid prototyping applications due to its versatility.

- Stereolithography (SLA) is popular for its high accuracy and its ability to produce models with fine details and smooth surfaces. It is widely used in jewelry manufacturing and in product design and prototyping where high resolution and a quality finish are required.

- Selective Laser Sintering (SLS) is mainly used to manufacture functional parts and prototypes in a wide variety of materials.

On the other hand, some of the best practices or best practices of 3D printing are:

First, DfAM or Design for Additive Manufacturing, as it is critical to design models that are specific to 3D printing and understand the limitations and capabilities of the technology.

On the other hand, when 3D printing, the orientation of the model and the placement of the supports are very important factors, as they can significantly affect the quality and strength of the part.

Finally, printer calibration must be taken into account to ensure optimum accuracy and consistency of prints.

How does artificial intelligence affect 3D printing?

When several technologies converge, it is very easy for innovation to occur extremely quickly. This is happening with the advances in the manufacturing process of parts through 3D printing and with the improvements brought about by Artificial Intelligence in this technology.

One of the main advantages of AI is its ability to analyze large data sets to find patterns or errors. By now, AI has proven to be an exceptional tool for tedious and repetitive tasks.

On the other hand, it has also been proven that all tasks related to creativity and imagination are best left to humans, although AI is also improving in this area.

Ultimately, as AI models continue to grow and improve, the impact it has on technologies such as 3D printing will only increase.

When to make the switch from CNC machining to 3D printing

Today, additive manufacturing has already found its way into virtually every industry – from automotive to fashion. However, before the innovation brought about by 3D printing, CNC machining dominated the world of part and prototype manufacturing.

On the one hand, 3D printing is a constantly evolving technology and is ideal for rapid prototyping using digital design, while CNC machining is excellent for functional prototypes and production models.

Therefore, it is necessary to understand and analyze the advantages and disadvantages of both processes before making a decision to produce parts or prototypes. Both 3D printing and CNC machining are fundamental tools in the development of new products.

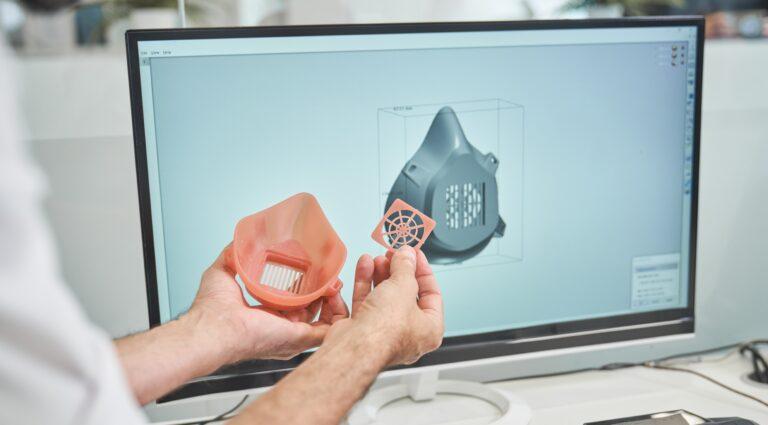

3D Printing: How does it enrich product design?

The first 3D printing technologies were developed in the 1980s and enabled product designers to create 3D models and physical parts or prototypes.

Additive manufacturing offers a number of advantages that enrich the product design process, from rapid prototyping to customization, including the ability to create complex designs and cost optimization.

In short, we can say that the innovations and improvements offered by 3D printing for the manufacture of parts and prototypes are promising and will continue to evolve in the coming years.

At Proto&Go! we aim to provide you with the best service for the development of your parts through additive manufacturing.

Request your quote now through our website!