Modern CNC milling machines, i.e. CNC machines designed to cut or shape materials by using a rotating tool, are capable of manufacturing parts and prototypes quickly and reliably. This is thanks to its ability to move along several axes of travel.

These machines are classified by the number of axles with which they operate. The most common are 3, 4 and 5-axis CNC milling machines. The axes determine the characteristics of the part or prototype and affect production efficiency and accuracy.

In this article we tell you about the advantages of each of these CNC milling machines so that you can find out if CNC machining is the right technology for your project:

Advantages of each CNC milling machine (3, 4 and 5 axes)

3-axis milling machine

They are used for a wide variety of milling operations. These machines are ideal for fast and efficient material removal and, above all, for producing flat or planiform surfaces. Although it has the ability to make rounded profiles, it is not ideal for this task, so it is recommended to use it simply for prismatic (i.e. mainly rectilinear) shapes.

3-axis milling machines are typically used for drilling and tapping holes along the Z-axis only, as the spindle is not designed for drilling holes. This can be a limitation in some instances where parts need holes or cavities machined on multiple faces.

4-axis milling machine

The addition of another axis means many new machining possibilities, as the rotary table allows a part to be mounted at one end of the machine and then rotated to access the other sides of the part.

The main limitation of the 3-axis milling machine disappears since, as the workpiece is partially suspended, it is possible to drill holes or other elements that completely penetrate the workpiece.

In addition, more complex curves and contours are also possible thanks to the rotation of the workpiece while machining.

5-axis milling machine

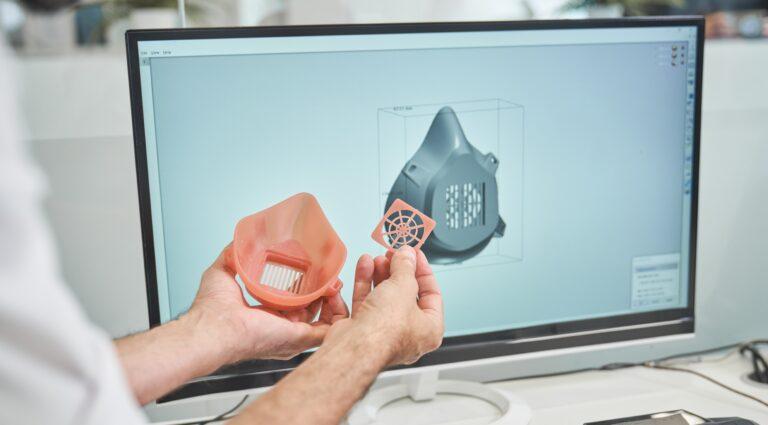

With this milling machine it is possible to produce more sophisticated shapes, i.e. shapes with complex compound curves in multiple directions.

A 5-axis machine is usually much more rigid, as it must maintain accuracy even while moving in many directions simultaneously.

CNC machining at Proto&Go!

In short, the difference between a 3, 4 and 5-axis CNC machine lies in the ability to rotate in different planes. Both 4-axis and 5-axis CNC milling machines allow rotation in different coordinates. This quality results in the production of more complex shapes more easily.

At Proto&Go! we offer industrial machining solutions thanks to our state-of-the-art machinery, which have 3, 4 and 5-axis capabilities. We use CNC machining to manufacture precise, high quality parts and have a wide variety of materials, both plastics and metals.

What are you waiting for? Request your quote online now!