CNC machining has become a key tool for product customization in many industries, enabling companies to manufacture unique parts with high precision and adaptability. This approach not only responds to specific customer needs, but also offers a great competitive advantage by differentiating itself from standardized production.

On the other hand, the integration of CAD/CAM technologies has been fundamental in this process, as it facilitates the creation of detailed 3D designs and ensures that tool paths are accurate, which optimizes both design time and final product quality.

One of the biggest advantages of CNC machining is its ability to accelerate prototyping and design validation, which is crucial in industries where precision and safety are essential. Flexibility in the use of materials also broadens the range of applications, allowing work with metals, plastics and advanced composites to meet specific strength and durability requirements.

This versatility not only drives innovation in new product development, but also allows companies to remain competitive by offering solutions that are not possible with conventional manufacturing methods.

General rules and size limitations in CNC machining

CNC machining is a versatile and precise process, but it has a number of size constraints determined by several factors. These constraints depend primarily on the physical dimensions of the CNC machine workspace, axis travel and the number of available axes.

In addition, more complex parts may face limitations on elements such as threads, holes, cavities, threads and recesses.

In the case of CNC turning, size restrictions are due to the distance between axes, turning distances and part mounting, which influences component manufacturing.

Safety basics and safety tips for CNC machines

CNC machine safety focuses on minimizing the risks of accidents and injuries associated with equipment such as CNC milling machines, lathes and drilling machines. These machines present numerous hazards, from moving parts and hot surfaces, to slippery fluids, sharp edges, or sparks and chips, which can pose a threat to operators without proper guarding.

It is therefore essential to understand the safety measures when working with this type of machine, as risks can arise both during everyday tasks and in the event of exceptional mechanical failures.

CNC Lathe and CNC Milling Machine: main features and differences

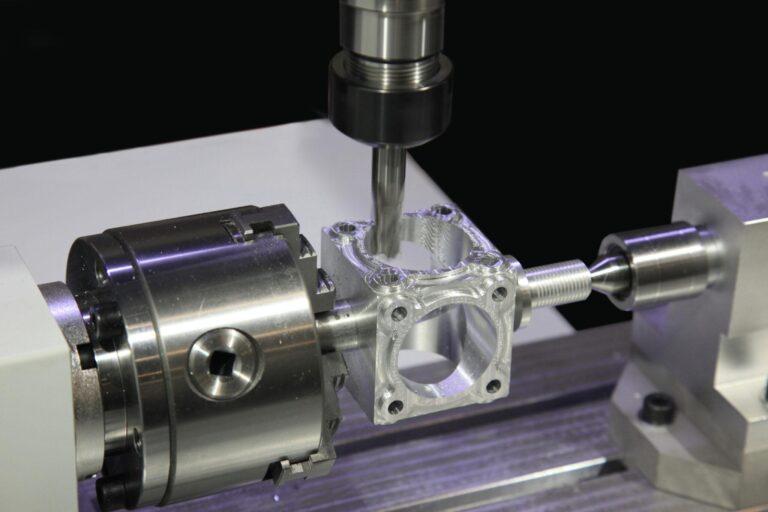

The CNC lathe and CNC milling machine are key tools in the machining and cutting of parts, widely used in various industries. Despite their popularity, they still generate confusion regarding their differences and specific characteristics.

The main difference lies in the movement of the material. On the CNC lathe, the workpiece rotates constantly while the cutting tools remain stationary, allowing the creation of cylindrical shapes. On the other hand, the CNC milling machine is also a rotary machine, but in this case, the cutting tool is the one that rotates and moves along several directions, which offers greater versatility in the type of operations and shapes that can be machined.

In short, we can say that the ability to customize CNC machining and its tools strengthens the relationship between companies and their customers. By meeting individual needs, companies not only increase satisfaction, but also foster loyalty and generate positive recommendations, which helps to consolidate their reputation in the market.

At ProtoandGo! we offer the best CNC machining service for your parts and prototypes. You can request your quotation through the form on our website in a quick and easy way.

What are you wating for? Request your quote now!