The combination of 3D printing and robotics is leading to a paradigm shift in multiple industries, from manufacturing and medicine to construction and even space exploration. Both technologies, which alone have already transformed their respective fields, are joining forces to create new, more efficient and customized solutions.

In this article, we tell you how these technologies complement each other and the innovations that are emerging from this merger.

3D Printing: beyond manufacturing

3D printing, also known as additive manufacturing, makes it possible to create three-dimensional objects from a digital model, adding successive layers of material until the final product is formed. Although this technology began as a tool for rapid prototyping, today it has expanded to a wide range of applications, from the manufacture of customized parts to the creation of medical prostheses or even the construction of houses.

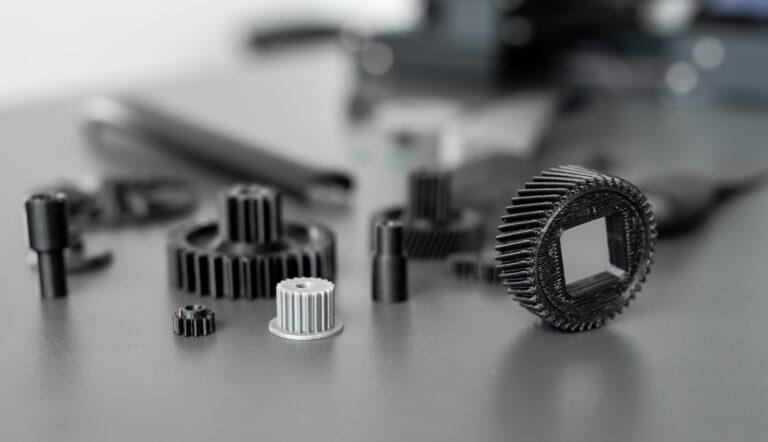

One of the most outstanding features of 3D printing is its ability to customize products accurately and efficiently. Instead of relying on massive molds and expensive production lines, additive manufacturing allows for the creation of custom parts according to the user’s specific needs. In addition, 3D printing significantly reduces material waste, making it a more sustainable option compared to traditional manufacturing methods.

The advent of new printing technologies, such as those using advanced materials (carbon fiber reinforced plastics, metals, ceramics…), has greatly expanded the possible applications of 3D printing.

Robotics: the new era of automation

Robotics has been another area that has undergone significant development in recent decades. Robots, originally used in industry for repetitive tasks, are now designed to perform complex activities that require greater flexibility and adaptability. Thanks to advances in artificial intelligence, sensors and control systems, modern robots can interact with their environment, learn from it and make decisions in real time.

Robotic automation is not only limited to industrial production, but has also expanded into areas such as robot-assisted surgery or autonomous logistics. Collaborative robots, also known as cobots, are designed to work alongside humans, allowing companies to increase productivity without replacing human workers.

The development of robots with machine learning capabilities and advanced sensors allows them to adapt to a variety of tasks without the need for reprogramming. This versatility is transforming sectors such as agriculture, healthcare and entertainment, enabling new forms of interaction and innovative solutions to complex problems.

The synergy between 3D printing and robotics

When we combine 3D printing and robotics, the benefits of both technologies multiply, opening up an even wider range of possibilities. Robots, when designed and manufactured through 3D printing, can benefit from customization and more efficient production than was previously unthinkable. This is known as additive robotic manufacturing.

On the other hand, the manufacture of customized robots using 3D printing makes it possible to design specific parts that perfectly fit the needs of the robot or its environment. An example of this is the creation of biomimetic robots (inspired by nature) that use 3D printed parts to emulate the movements of animals or even humans. This approach is especially useful in rescue robots, which must be able to adapt to difficult terrain, or in medical robots, which must have sizes or shapes adapted to very particular patient conditions.

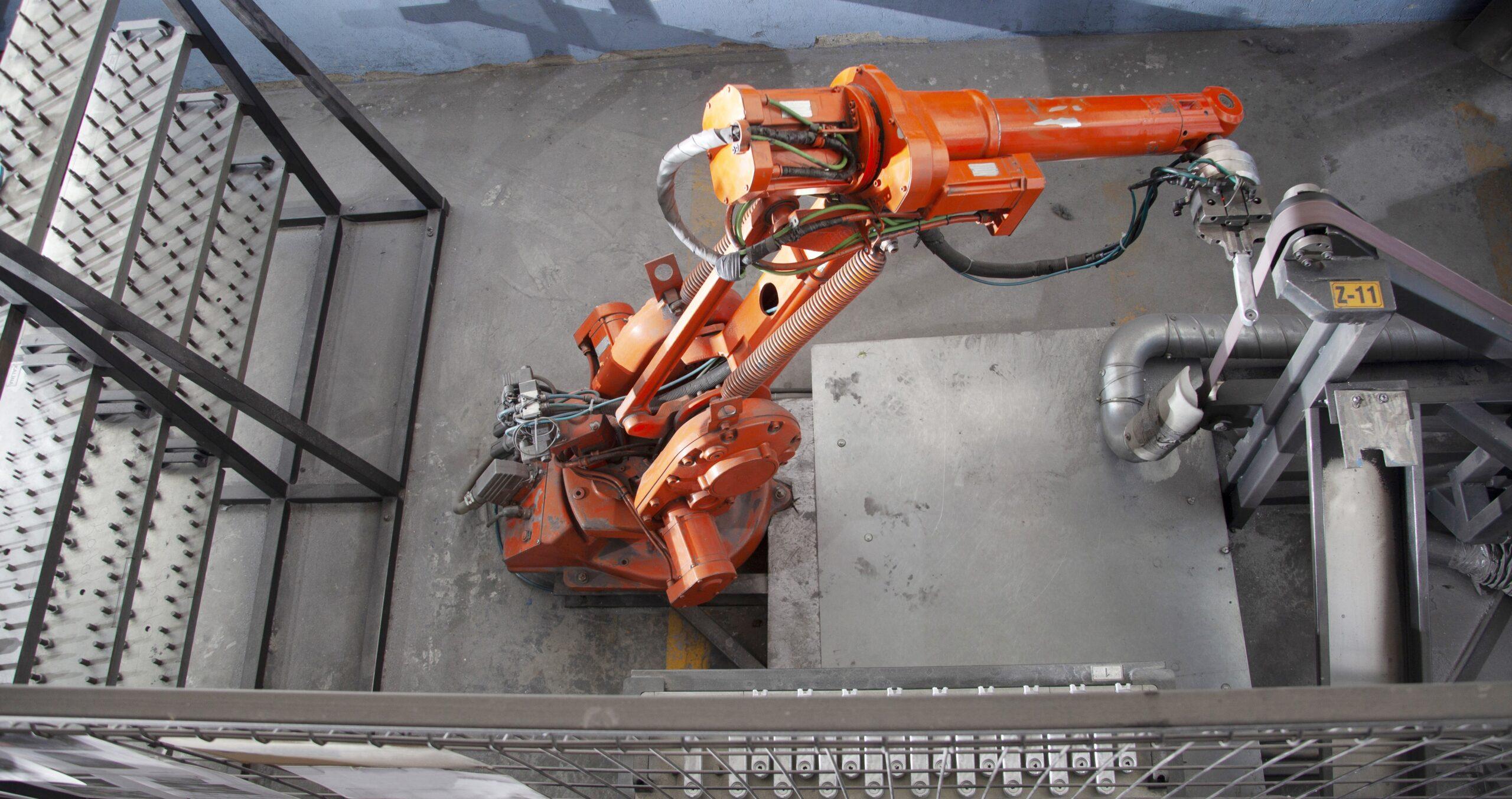

On the other hand, robots are also optimizing the 3D printing process. Through a robotic arm, for example, complex printing tasks can be performed in larger spaces and with greater precision than traditional 3D printers would offer. This integration can improve manufacturing speed and, at the same time, reduce the possibility of human error. In addition, robots can be equipped with intelligent sensors that monitor the printing process in real time. This allows parameters such as temperature, extrusion speed and layer alignment to be adjusted while the printer is running, which improves the final product quality.

In short, we can say that 3D printing and robotics are two of the most disruptive technologies of recent years. Their fusion is enabling the creation of faster, more efficient and customized solutions in a wide variety of fields. From manufacturing customized parts and robots to creating structures in space, this synergy promises to transform the way we work, produce and live. The possibilities are endless, and as both technologies continue to evolve, their impact will be even more profound, opening new doors to innovation around the world.

At Proto&Go!, as a leading 3D printing company, we offer 3D printing solutions for companies looking to optimize their production process. With our industrial 3D printing services, we are ready to help companies transform their ideas into tangible realities, improving their competitiveness in a constantly evolving market.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!