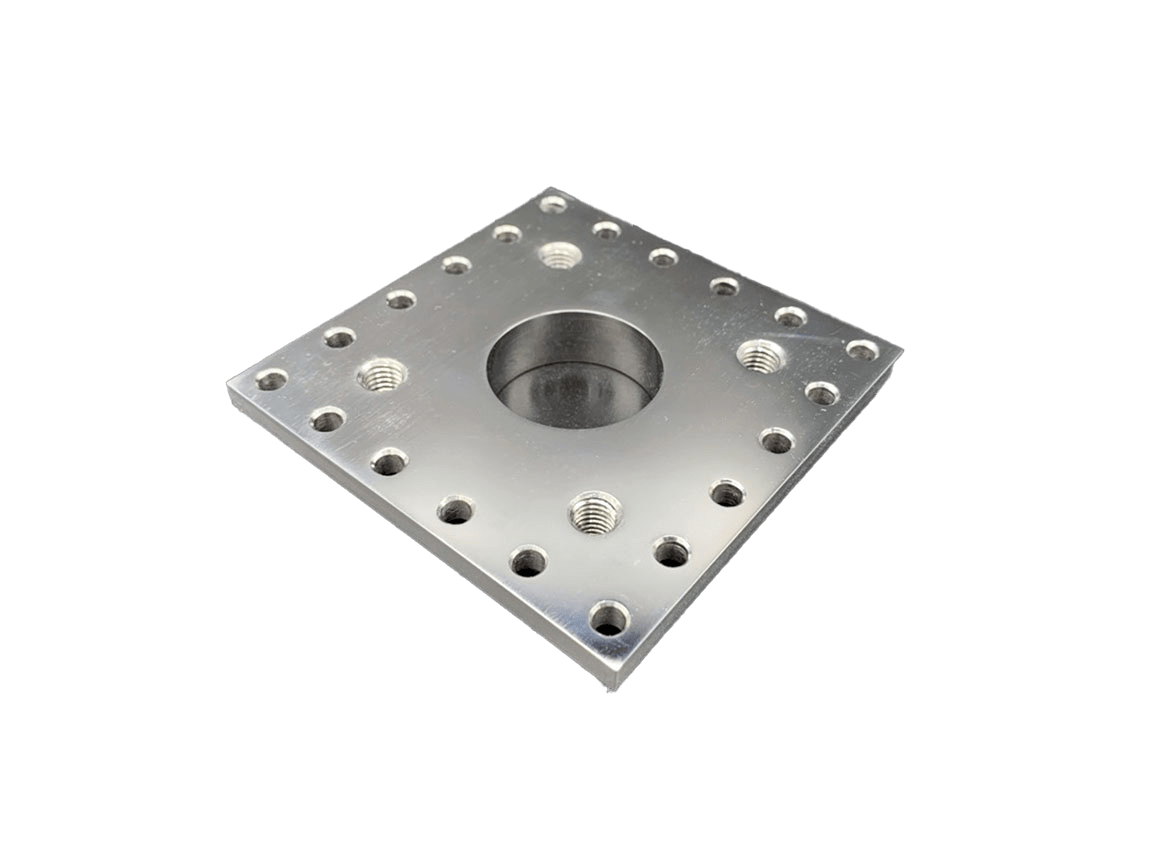

Description

Metals

Plastics

Stainless steel is a highly corrosion resistant steel with a low carbon content and a minimum of 10% chromium in its alloy. It is a solid material, ideal for machining with high resistance to corrosion and highly recommended for use in industry, automotive, aerospace and even jewellery.

Technology

CNC Machining

Features

- High corrosion resistance

- Easy prototyping

- No post-welding treatment required

- Non-hardenable and non-magnetic

- Recyclable

Applications

- Cutlery and kitchen utensils

- Industrial chemistry

- Energy generation

- Food production

- Jewellery, 316L alloy

- Medical applications

- Automotive

Colours

Properties

- Density: 7.96 g/cm-3

- Modulus of elasticity: 190-210 GPa

- Melting point: 1370-1400 C

- Tensile strength: 460-806 MPa

Alloys

Not specified

The most economical option. We will choose the most suitable alloy according to the geometry and available stock.

AISI 304

Most commonly used alloy. Applications, from the manufacture of kitchen utensils to chemical processing equipment.

AISI 316L

Excellent corrosion resistance properties. For use in harsh environments, marine or chemical processing applications. High cost.

Finishes options

Polishing

Finish that achieves a smooth, glossy surface with low roughness.

Sandblasting

Surface matting that eliminates machining marks.

Painting

Powder coating in the desired colour. RAL o Pantone.

Proto&Go! puts at your disposal all its technology to obtain CNC machining in stainless steel.

Thanks to the specific software developed by Proto&Go! you can now request your stainless steel machining offers easily through our online form and receive them anywhere in the world by express delivery.

Our CNC machining technology can accommodate both simple stainless steel prototypes, common in industry, as well as 3D prototyping of complex surfaces, thus offering a real alternative to 3D printing or sintering.

Select Stainless Steel from our 100+ available materials, both plastic and metal, upload your 3D files and within 24 hours you will receive an online quotation with an estimated delivery time.

Do not hesitate to request an offer without obligation and benefit from a technology currently only available to large companies at prices within the reach of any user.

Thank you for trusting in the machining services of Proto&Go! to obtain your prototypes and unique parts in stainless steel.