Description

Metals

Plastics

It is a polymer used in many industrial processes. It is the result of a mixture of polyol and isocyanate. Its applications are very diverse and, in addition to being more flexible than other similar agents, it stands out for its resistance to the impact of chemical solvents and can therefore be used in a wide variety of production processes.

Technology

Vacuum Casting

Features

- Tear resistance

- Oil resistance

- Excellent elasticity at low temperatures

- Widely used for pre-series

Applications

- RIM/RRIIM systems

- Acoustics

- Industrial sector

- Furniture

- Technical laboratory equipment

Colours

Properties

- Temperature: 80ºC

- Density: 0.99-1.19 g/cm3

- Tensile strength: 1.5-40 Mpa

Datasheet

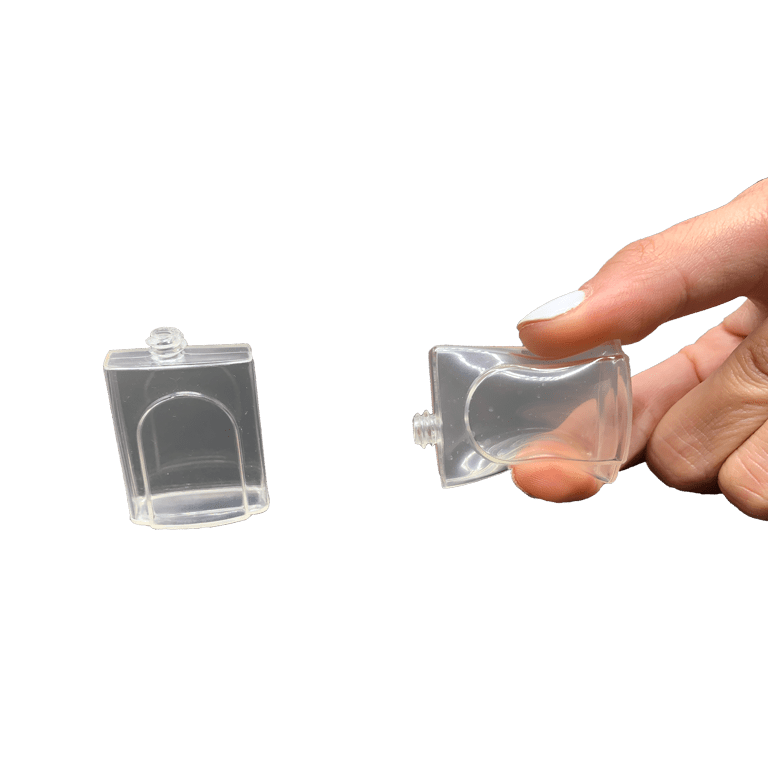

Proto&Go! puts at your disposal all its technology for the production of silicone moulds in PU – Transparent flexible polyurethane.

Thanks to the specific software developed by Proto&Go! you can now request your offers of transparent flexible Polyurethane silicone moulds easily through our online form and receive them anywhere in the world by express delivery.

Our silicone moulding technology accommodates both simple industry standard transparent flexible polyurethane prototypes and complex surface 3D prototyping, offering a real alternative to 3D printing or sintering.

Select transparent flexible polyurethane from our 100+ available materials, both plastic and metallic, upload your 3D files and within 24 hours you will receive an online quotation with an estimated delivery time.

Do not hesitate to request an offer without obligation and benefit from a technology currently only available to large companies at prices within the reach of any user.

Thank you for trusting in the silicone moulding services of Proto&Go! to obtain your prototypes and unique parts in PU – Transparent flexible polyurethane.