In the world of additive manufacturing, every design and configuration decision has a direct impact on the final part outcome.

Among the critical factors, part orientation in the 3D printing process is one of the most critical variables in both surface quality and mechanical properties of the product. Understanding its implications is essential for engineers, designers and technicians seeking to optimize their results.

In this article, we explore how the orientation of a part during 3D printing can influence key aspects such as surface quality, structural strength, material usage and production time. Through technical and applied insight, we highlight the main criteria for making sound decisions in additive manufacturing processes.

What does it mean to orient a part in 3D printing?

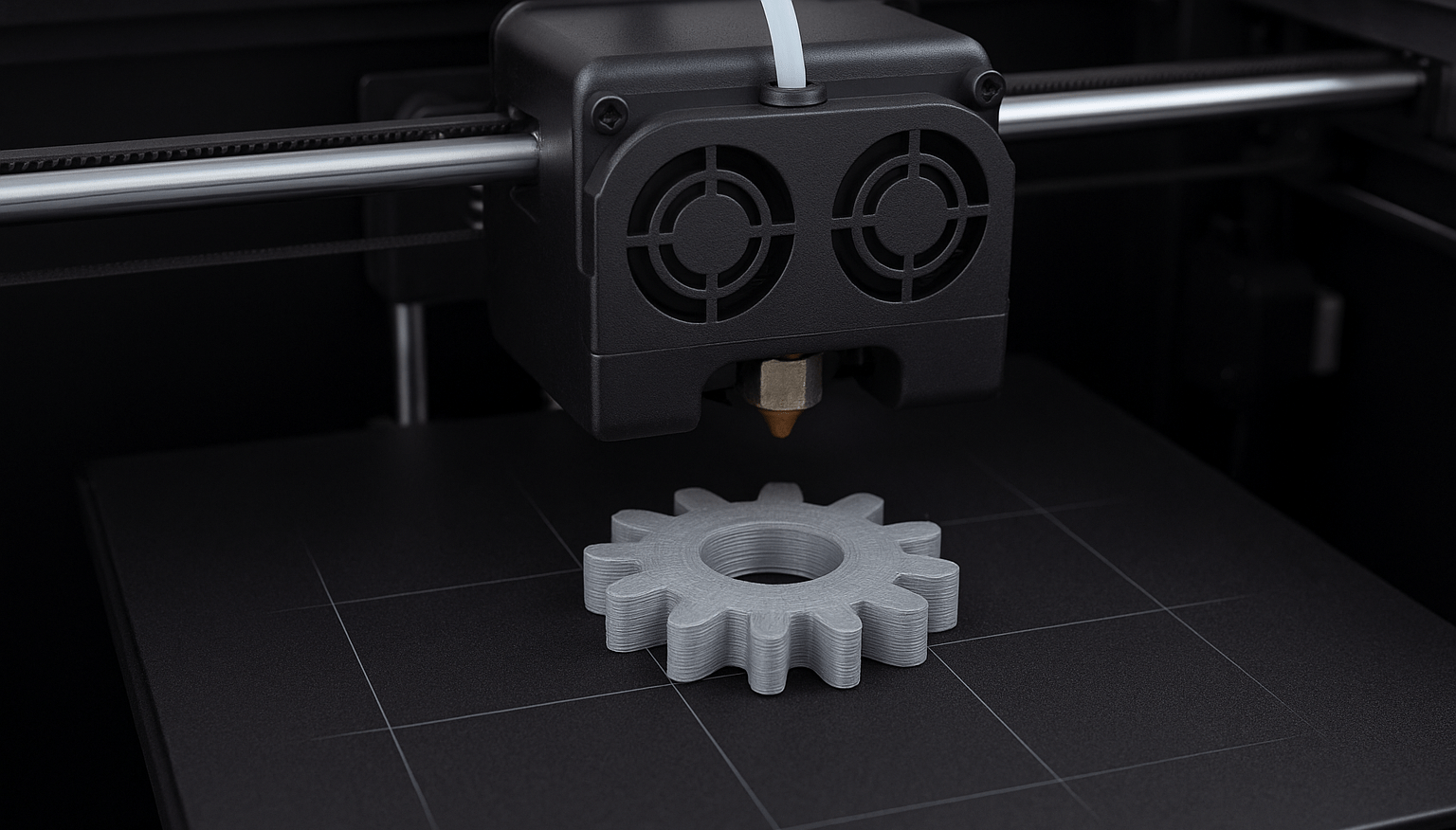

Orienting a part in 3D printing involves defining how it is positioned on the print bed. Depending on the technology used (FDM, SLA, SLS, etc.), this orientation will directly affect:

- The need for supports

- Printing time

- The direction of the layers

- The quality of details and finishes

- The mechanical strength of the part

Upward- or side-facing surfaces often show better finishes than downward-facing surfaces, especially in technologies such as FDM or SLA. Horizontal layers build up more evenly, while cantilevered or sloped areas require supports that can leave marks after removal.

One technique to improve surface quality is to tilt the flat surfaces of the part at an angle of 10 to 15 degrees, which helps minimize visible marks and coating lines.

Therefore, for aesthetically visible parts, it is recommended to orient the main surface upwards or in a vertical plane if a clean and homogeneous finish is desired.

Mechanical properties in 3D printing

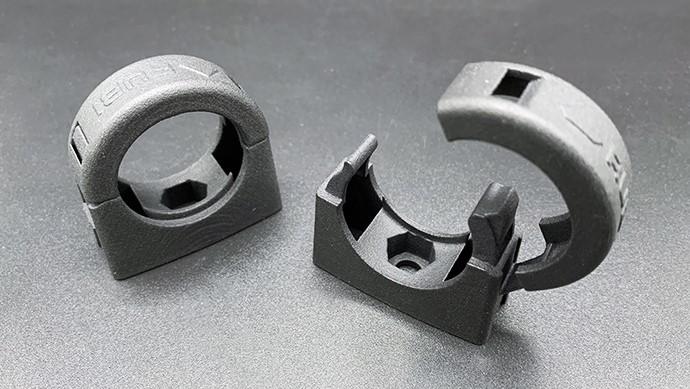

In 3D printing, the direction of the layers influences the structural strength. Parts are generally stronger in the plane of the layers (XY) and weaker in the vertical axis (Z), where the layers can peel off with less effort.

To optimize the mechanical strength of 3D printed parts, it is advisable to align the orientation of the part with the forces that will act on it in real use, taking full advantage of the direction of the layers.

Therefore, if a part is to be subjected to stresses or loads, it is important to align the orientation so that the forces are distributed along the layers, not between them.

Use of media and material consumption in industrial 3D printers

Improper orientation can significantly increase media usage, increasing printing time, media waste and the possibility of defects upon removal.

To reduce the number of supports, it is advisable to orient the parts so that the surfaces requiring them are at the base and overhangs greater than 45° are minimized, facilitating cleaner and more efficient printing.

Optimizing orientation can reduce the number of support structures required, especially in FDM printing, where overhangs greater than 45° tend to fail if not supported.

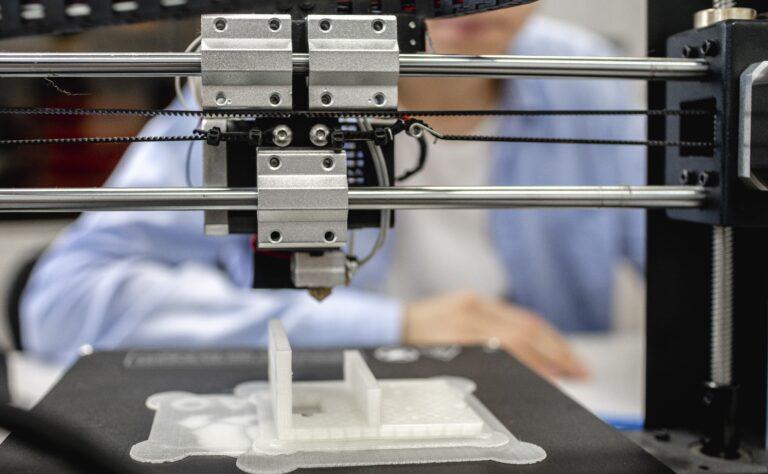

Manufacturing time and efficiency in rapid prototyping

Printing time is also affected by orientation. Parts that are printed “lying down” tend to require fewer layers than if they are printed vertically, which speeds up the process.

A good practice to reduce manufacturing time is to reduce the overall height of the part in the Z-axis, which reduces the number of layers and therefore the printing time.

In rapid prototyping, where time is critical, efficient guidance can make the difference between meeting or missing a deadline.

In short, we can say that the orientation of the 3D printed part is not a minor detail: it impacts strength, aesthetics, cost and manufacturing time. Choosing the best orientation requires balancing all these factors according to the intended use of the part.

At Proto&Go! we specialize in HP’s Multi Jet Fusion (MJF) 3D printing technology, designed for industrial applications. This technique allows us to manufacture parts in different materials for 3D printing, such as Polyamide PA12, a rigid and resistant material, or TPA, a robust and flexible material.

Don’t wait any longer and request your quote through our website!