3D printing technology has radically revolutionized the way we create designs and objects. This advance has allowed us to generate detailed and accurate three-dimensional models from simple 2D images.

In this article we show you the necessary steps to transform your two-dimensional images into three-dimensional objects ready to be printed:

Principles of 3D printing

By 3D printing we mean the different procedures from which the physical construction of a 3D design can be achieved by means of the additive manufacturing technique.

In additive manufacturing, the geometry is obtained from the layer-by-layer solidification of the starting material.

If we talk about materials, it is a technique in which the use of plastics is more common. Even so, other materials such as metal are slowly making inroads.

From 2D image to 3D file

It is important to understand the general process of converting 2D images (PNG or JPG) into 3D STL files (the standard format used in this technology). This procedure involves several steps:

- Select a 2D image and prepare it: once you have your 2D image, it is usually necessary to edit it to highlight the areas you want to make three-dimensional, as well as to remove unwanted elements. This step can be performed in any image editing software such as Photoshop, GIMP or other design programs.

- Conversion to black and white: this is a step that can make the process easier, as it is a simpler representation of depth.

- Import the image into a 3D tool: thanks to this you can adjust the height and other details to achieve the desired dimension.

- Export as STL file: once the model is ready, it is necessary to export it as an STL file in order to print the 3D parts.

For the realization of this process there are several programs or tools such as: Blender, Illustrator, Photoshop or Vectary. These tools provide you with several options for converting 2D images into 3D models and each program has different advantages and level of complexity. In this way, you can choose the one that best suits your needs or your knowledge.

3D printing at Proto&Go!

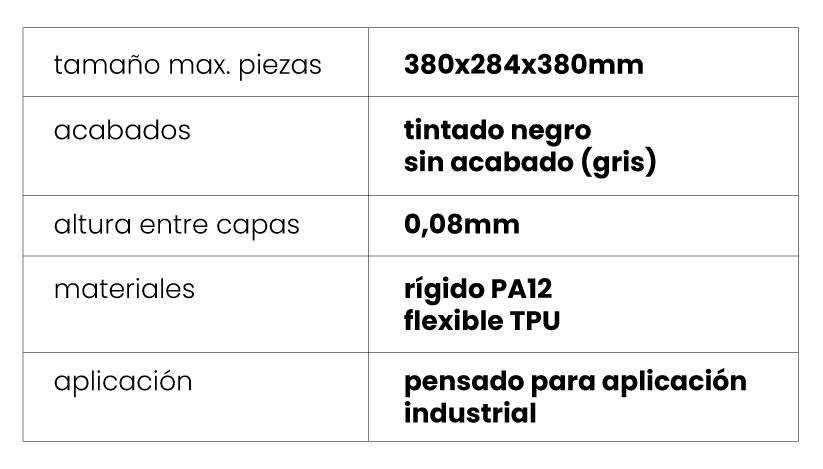

At Proto&Go! we use HP’s MJP (MultIjet Fusion) technology, which is the latest and most advanced industrial grade printing technology. It stands out for its manufacturing speed and the strength of the parts obtained and is commonly used, at industrial level, for the rapid creation of both prototypes and complete productions.

Most of the parameters required for the printing strategy (such as the position or orientation of the parts) are defined directly by the 3D printing technicians to optimize the results. Even so, during the design and product development phase, designers may have considerations that ensure the manufacturability of the part and also help to obtain more economical parts.

At Proto&Go! we have put together some of the best practices to keep in mind when designing a part. Find them out in our 3D printing guide!

In addition, through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you waiting for? Request your quote now!