The constant search for new materials, tools and techniques suitable for the manufacture of parts is something that is happening in all industries.

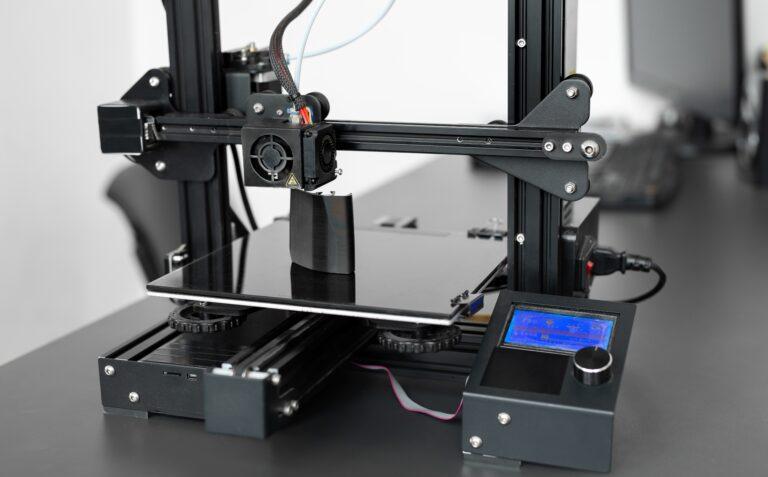

Thanks to recent improvements in the speed and accuracy of printing systems, large-scale 3D printing is no longer a promise but a reality.

On the other hand, printers are being developed that use recyclable materials for the creation of prototypes and even objects such as furniture.

If we talk about the future, the year 2024 is expected to see a further expansion in the variety of materials available, as well as integration with other technologies such as robotics and the Internet of Things (IoT). In this way, technology is increasingly geared towards automated and customized manufacturing on a large scale.

The Importance of 3D Printing in STEM Education

Increasingly, education is looking to provide instruction that helps students develop the skills they need to thrive in their future careers.

Nowadays, educational centers continually seek to provide students with experience and to enhance the practical part, especially in scientific careers.

One of the main ways to support students in this regard is through 3D printing technology, as it allows them to create physical 3D objects from digital designs. In this way, they are provided with a hands-on, interactive learning experience.

How 3D Printing is Revolutionizing the Aerospace Industry

The aerospace industry is an extremely demanding environment, requiring components capable of withstanding continuous wear and tear and high precision and temperature conditions.

During the initial stages of the evolution of 3D printing, this manufacturing method was considered a very innovative but rather limited technology. Today, additive manufacturing has evolved tremendously and is a fully developed industry, with great design flexibility, specialized software and a wide range of materials and 3D printers designed for different applications.

5 myths of additive manufacturing

Since the invention of the 3D printer, and throughout the evolution of this technology, many myths and misconceptions have been shared about it. Some of the clearest examples are:

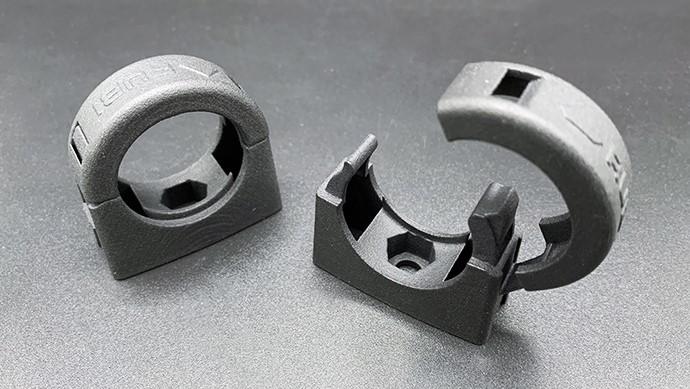

- Additive manufacturing or 3D printing systems produce ready-to-use parts or complete products: while there are exceptions, most parts manufactured by 3D printing require the removal of support material, surface finishing or the addition of a clear coat.

- Additive manufacturing is fast and economical: this is true if relatively small parts are produced in short runs. On the other hand, compared to large volumes of parts manufactured by injection molding, 3D printing can be slower and more expensive.

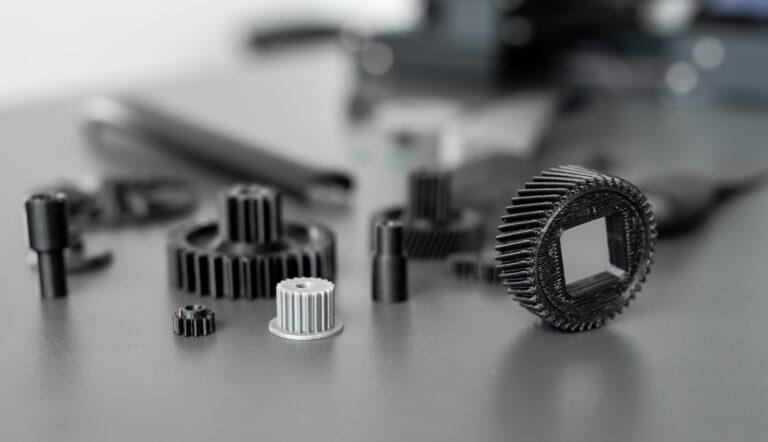

- Parts manufactured by 3D printing are not as good as those manufactured by conventional methods: in this case, it may depend on several factors. Even so, thousands of parts have already been manufactured by additive manufacturing with a high precision and quality and for numerous applications such as: medical components, industrial machines, automotive parts…

- Few materials are available: in this case we can say that this was true years ago, but, nowadays, numerous material options for additive manufacturing have become commercially available.

- Additive manufacturing systems can print human organs: this claim could be considered one of the biggest myths related to 3D printing. Although some first samples have been produced, this project is still in the research and development phase and is still a great challenge for the professionals.

At Proto&Go! we provide the best service for the development of your parts and prototypes through additive manufacturing. In addition, we are specialized in printing by Multi Jet Fusion or MJF, the latest technology of the HP company specially designed for industrial applications.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!