The growing popularity of polyurethane parts in the vacuum casting is due to its unique properties. This material combines lightness with remarkable strength, making it an ideal choice for various applications, from automotive components to consumer products. The versatility of polyurethane allows for the creation of customized parts with specific properties.

The manufacturing of parts through vacuum casting has experienced significant advances in recent years, and emerging trends point towards a promising future. In this article, we will explore the trends that are shaping the future of the vacuum casting, highlighting improvements in efficiency, innovative materials, and cutting-edge design methods.

Trends in Vacuum Casting

In a world where quality, speed and cost-effectiveness are essential, vacuum casting stands out as a crucial method, especially in terms of prototyping and mass production. Discover the latest trends:

Increased Adoption of Automation

Automation is positioned as the main driver behind trends in silicone molds. Injection molding is already a highly automated industry, especially for large production volumes; however, there is still room for silicone mold facilities to implement advanced technologies.

Today, robotic systems are becoming increasingly user-friendly and cost-effective as more companies enter the market and integrate automated systems to optimize efficiency, reduce costs, and cycle times.

Innovations for Unparalleled Efficiency

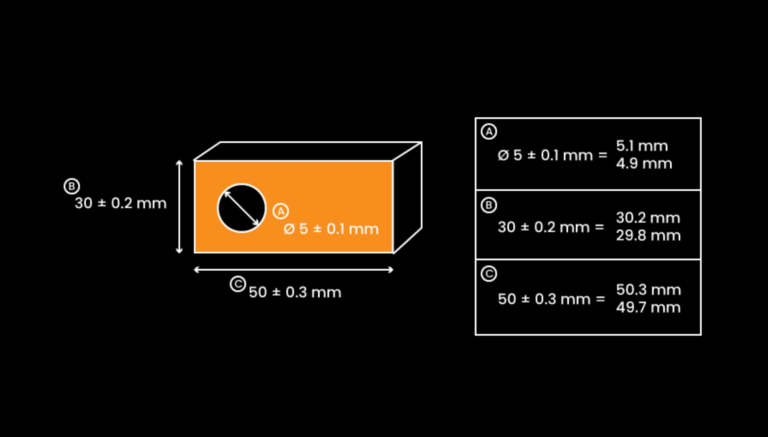

Advances in machinery, process control and automation are paving the way for faster and more accurate production. The ability to reduce cycle times without compromising quality is a determining factor in the widespread adoption of this technique in various industries.

The constant evolution of technology drives significant improvements in the efficiency of vacuum casting. The flexibility and extreme temperature resistance of silicone allows detailed reproduction of complex parts. In addition, the durability of these molds facilitates the mass production of parts, saving time and costs.

Increased Focus on Sustainability

Sustainability has become an undeniable priority in manufacturing, and in vacuum casting, it is no exception. From choosing more eco-friendly materials to implementing recycling processes in production, the industry is focusing on reducing its environmental impact.

The pursuit of more sustainable solutions not only responds to the growing environmental awareness but also aligns with the expectations of conscious consumers. This, in turn, has increased the demand for sustainable products, leading companies to incorporate biodegradable or recyclable plastics into their offerings.

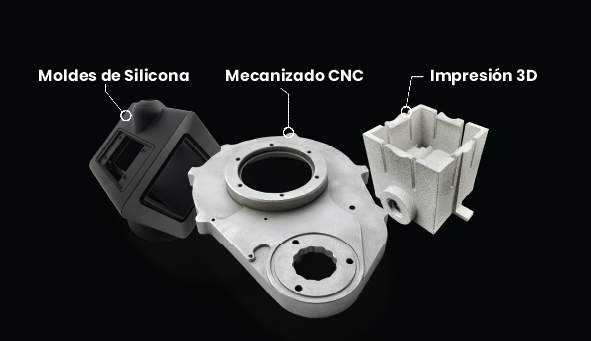

Adoption of New Technologies

From the use of smart sensors to monitor the process in real time to the implementation of 3D printing technologies for advanced mold manufacturing, the adoption of new technologies is driving the quality and efficiency of vacuum casting.

AI has not yet had a direct effect on silicone molding equipment, but there is great potential for AI-driven productivity increases across industries. Meanwhile, Industrial Internet of Things (IIoT) technologies from Industry 4.0 are already collecting real-time production data to enable the vacuum casting to improve production rates and reduce costs.colada al vacío.

On-Demand Injection Molding

The era of on-demand production is transforming the way silicone mold projects are approached. Flexibility in scheduling and the ability to quickly switch from one piece to another are gaining importance This translates into an agile response to market needs, enabling companies to adapt quickly to changing customer requirements.

Applications in the Manufacturing of Specialized Parts

The synergy between silicone molds and polyurethane parts has opened up new possibilities in the the manufacture of specialized parts. From prototypes to final components, the combination of these elements provides customized solutions for a wide range of industries The ability to replicate fine details and achieve specific properties makes this technique essential in modern manufacturing.

Vacuum Casting: Perspectives for the Future

As technology continues to advance, we can expect to see even more innovations in vacuum casting. Constant process optimization, the introduction of advanced materials and precise part customization are areas that will continue to evolve significantly in the future.

At Proto&Go!, we aim to provide you with the best service for the development of your prototypes using the most advanced technologies. We produce high-quality silicone molds to ensure the consistent repeatability of production.

Request your quote now and receive your budget within 24 hours!