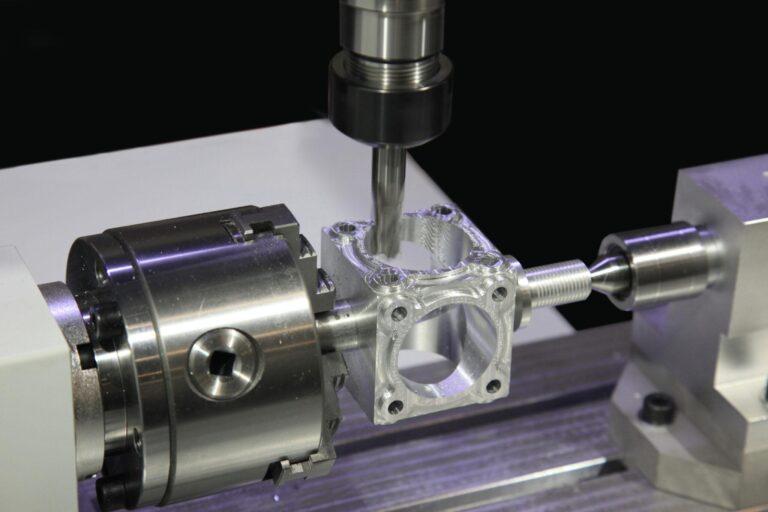

In recent decades, CNC machining has become a mainstay for the efficient and accurate production of parts and prototypes in a wide range of industries. However, with increased competition and pressure to reduce costs, companies are constantly challenged to optimize their CNC machining processes to improve efficiency and remain competitive in the marketplace.

In this article, we tell you key strategies and tips for optimizing the CNC machining process and reducing its associated costs, from intelligent part design to implementing advanced technologies and efficient management practices.

How to optimize the machining process?

First, it is essential to take manufacturing considerations into account in the design. When designing parts and prototypes, the capabilities and limitations of CNC machining must be kept in mind, i.e. avoid complicated features that can increase machining time and, therefore, associated costs.

On the other hand, the selection of materials and tools and their maintenance is also important. Use suitable materials that are cost-effective and easily machined. Some materials may be more difficult to machine or may even require special tooling, which increases costs significantly. Choosing the right tool for the job also ensures efficient machining and extends tool life.

Another factor that can help optimize the process is scheduling. Use efficient CNC programming software that generates optimal tool paths and minimizes unnecessary movements. This can reduce machining time and tool wear.

Lean Manufacturing at Proto&Go!

At Proto&Go!, we focus on making manufacturing fast and efficient by applying the Lean philosophy to all aspects of our business.

Lean manufacturing, or lean CNC machining, is a philosophy and methodology whose objective is to eliminate any activity or resource that does not add value to the product or customer. Such methodology involves the application of lean principles in CNC machining processes such as: setup time reduction, inventory minimization, defect elimination and workflow optimization.

It is an excellent methodology to optimize the machining process and to reduce the associated costs. It has several tools and techniques such as the 5S to organize and maintain an efficient workplace (sort, organize, clean, standardize and maintain).

Tips for reducing the costs associated with CNC machining

- Opt for simplicity: cavities that are too deep are not advisable. Although stiffeners or support structures could be used for support on these parts, this tends to increase costs, so the best advice for any machined part manufacturer or product designer is to keep it as simple as possible.

- Be careful with thin walls and shapes: thin walls may not only break during the machining operation, but may also flex later on. It is important to reinforce them as much as the design of the part allows.

- Explore cheaper alternative materials: one of the easiest ways to stay within budget or simply not to increase your budget is to switch to a material that is easier to machine and therefore cheaper. For example, copper is a very good electrical conductor, but aluminum is cheaper, almost as conductive as copper and much easier to machine.

- Avoid multiple surface finishes: there are some materials that require less surface polishing because they are highly machinable (aluminum, for example). A factor that also increases the final cost is the use of various finishes on the many surfaces of a part, so if possible, try to maintain consistent finishing criteria throughout the part and use finishes only when necessary.

Finally, an excellent tip for both optimizing the CNC machining process and reducing the associated costs is to constantly look for ways to improve machining processes (whether by implementing new technologies, optimizing workflows or recruiting staff).

On our platform, by sending 3D files, you can receive a feasibility analysis and an accurate quotation for your parts and prototypes in less than 24 hours.

What are you waiting for? Contact us if you have any questions or request your quote now on our website.