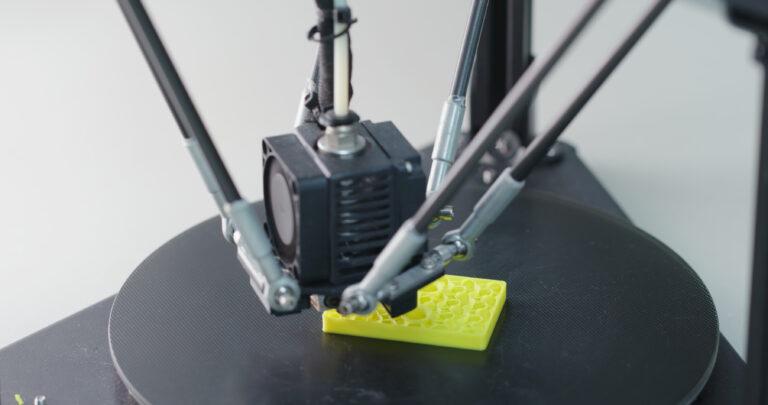

Advances in additive manufacturing and artificial intelligence are now poised to merge to achieve better results in considerably less time. This is because AI can improve all aspects of the 3D printing process, from idea conception to quality control.

In this article we tell you about some areas where AI is already powering3D printing or will do so in the near future.

Advantages and disadvantages of Artificial Intelligence

First, it is essential to understand the strengths and weaknesses of AI to understand how it affects 3D printing technology.

Artificial Intelligence has numerous advantages that may vary depending on the context and the specific application.

AI is an excellent tool for analyzing large data sets and finding patterns in them. It is able to automate repetitive and routine tasks, allowing companies to save time and resources.

In turn, it can also improve efficiency by performing complex tasks faster and more accurately than humans.

On the other hand, two of its great advantages are its capacity for innovation and customization. AI can help personalize experiences and recommendations for individual users based on their preferences and past behaviors. It can also drive innovation by enabling the development of new technologies and applications that were not possible before.

On the other hand, if we talk about creativity, it has been proven that it is better to leave all those tasks related to imagination and ingenuity in the hands of humans, although AI is also improving in that area.

Other limitations could be limited contextual knowledge and understanding and lack of common sense and emotional understanding.

Areas where AI and 3D printing meet

. 3D printing technology is relatively new and growing, so it is perfectly positioned to benefit from all the advantages and innovations that Artificial Intelligence brings. Here are some examples of how it does this:

- Generative design and shape optimization: can be used for the generation of complex and optimized designs that take full advantage of 3D printing capabilities. AI algorithms are able to optimize structures to improve strength, reduce weight and meet specific performance requirements.

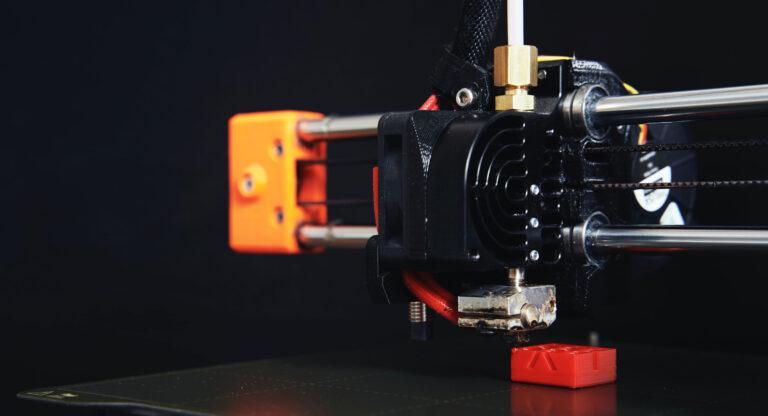

- Smart additive manufacturing: the combination of these two innovations enables smart additive manufacturing, in which AI systems monitor and control the printing process in real time. This reduces errors and corrects defects during printing.

- Accessibility of 3D printing: one of the key factors in which AI affects 3D printing is by making the technology more accessible to all.

- Customization and custom manufacturing: can be used to analyze user data and customize 3D printed products according to individual needs and wishes. A clear example of this is the manufacture of medical prostheses or orthopedic devices based on the characteristics and requirements of each user.

- 3D printer maintenance: is a technology that can be applied to predict and prevent 3D printer failures by analyzing sensor data and monitoring machine performance.

- Post-processing automation: after manufacturing parts and prototypes by 3D printing, many objects require post-processing such as support removal, polishing, painting or finishing. AI is an excellent tool to automate and optimize these processes, thus minimizing time and costs.

These areas of convergence between artificial intelligence and 3D printing are driving innovation in manufacturing, product design and customization, and have the potential to transform numerous industries and sectors in the coming years.

Ultimately, as AI models continue to develop and grow, the impact that it has on technologies such as 3D printing printing will only increase.

At Proto&Go! we aim to provide you with the best service for the development of your parts and prototypes through additive manufacturing.

Request your quote now through our website!