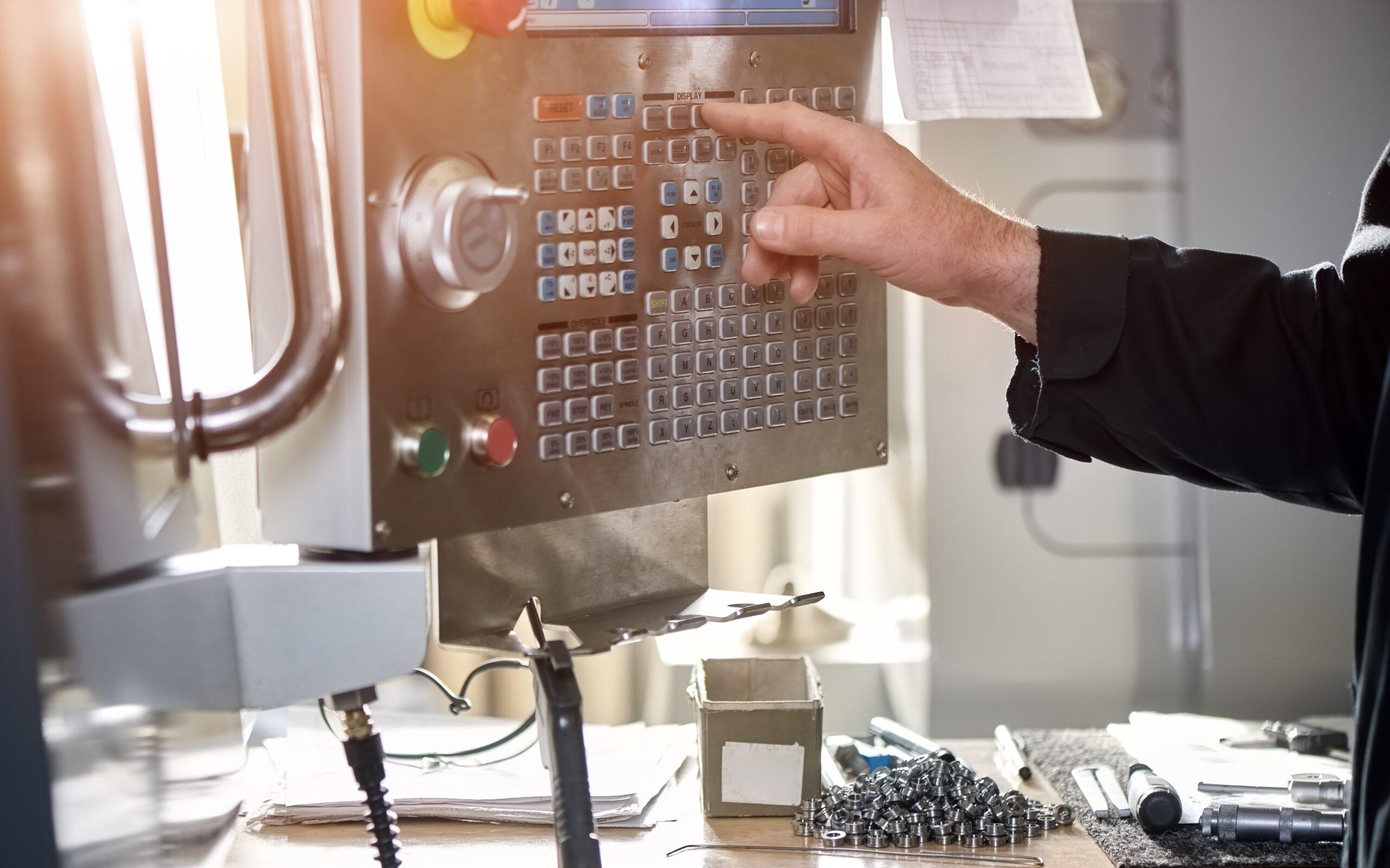

Artificial Intelligence (AI) is revolutionizing the manufacturing of parts and prototypes, especially through CNC machining. AI algorithms are capable of optimizing cutting paths and predicting machine maintenance, as well as making real-time adjustments.

All this greatly improves the accuracy, efficiency and automation of the machining process of parts and prototypes.

The integration of AI into machining technologies is a major game changer and offers numerous benefits such as improved quality control through AI-driven sensors, which are capable of performing inspections and analysis of parts during the CNC machining process. It also offers greater flexibility and adaptability and reduced operating costs.

Key industries using CNC machining

Generally, any industry that requires the manufacture of parts requires CNC machining directly or indirectly. Some of these major industries are:

Firstly, the aerospace industry, as it requires components of a very high level of precision.

On the other hand, the medical industry, since medical implants must be manufactured with advanced alloys, so CNC machines are essential for this manufacturing process.

Finally, the automotive industry also requires the manufacture of high-precision molds used for casting parts or high-tolerance machining.

All you need to know about CNC machining of different metals

Existen muchas opciones a la hora de escoger un material para un proyecto, y cada uno tiene diferentes ventajas y limitaciones. Therefore, it is essential to know the basic characteristics of commonly used metals:

First of all, one of the most commonly used metals is aluminum. This is due to its low density and properties such as strength and ductility.

Steel is also among the most widely used materials due to its relatively low cost and useful properties. There are different types of steel, which are manufactured using different alloying elements to achieve different properties. Some of the most popular examples are stainless steel or carbon steel.

Other materials commonly used for CNC machining of parts and prototypes are titanium, copper, brass, etc., among others.

The different machining tools

The efficiency of the machining process depends to a large extent on the machining tools used. Over the years, this technology has undergone significant advances in design, tooling and machinery.

There are different types of tools and each has had a different impact on the industry:

First, CNC lathes, or numerical control lathes, have revolutionized the way in which the machining process is carried out. These machines allow the production of parts with high precision and complexity.

On the other hand, similar to lathes, CNC drills also offer precision and automation in the drilling process. In this way, they guarantee hole accuracy and uniformity.

Finally, the most common tool type is high-speed milling cutters. They are used to shape materials by removing material. The cutting speed of these milling cutters offers higher production efficiency and, above all, higher surface quality of the machined parts.

At Proto&Go! we offer the best CNC machining service for your parts and prototypes. In addition, through our website you will be able to receive your quote in less than 24 hours.

What are you wating for? Request your quote now!