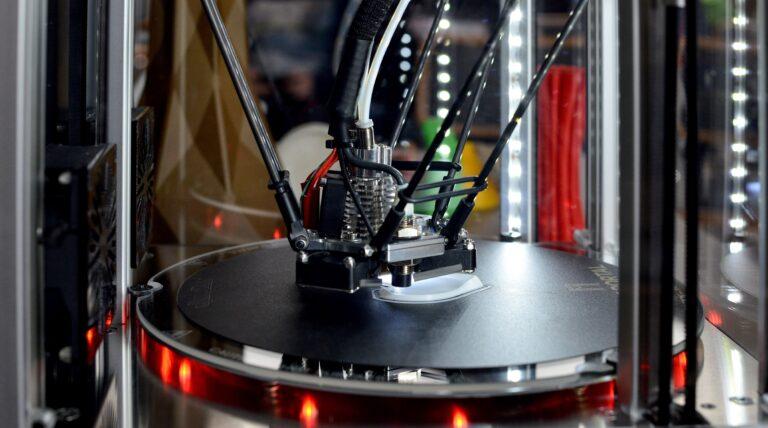

3D printing is a rapidly evolving technology that offers a wide range of benefits.

That technology that began as a tool for rapid prototyping has made a significant leap into widespread manufacturing. This evolution is transforming entire industries, enabling the production of parts and end products with unprecedented precision, customization and efficiency.

Everything you should know about 3D postprocessing

Post-processing is one of the most important steps in the 3D printing process, as it not only improves the aesthetic result of the printed part, but also its strength and other properties.

When talking about post-processing, we refer to all the processes performed after 3D printing a part. Some of these can be: sanding, painting, polishing, edge retouching…

On the other hand, although these processes are usually quite manual (spraying, sanding, gluing…), there are tools that can help automate or speed them up (such as an electric sander).

Is additive manufacturing the future of the construction industry?

The inclusion of additive manufacturing in the construction industry has had a major impact globally. This is due to its characteristics to reduce both costs and lead times and because of the complexity of designs in projects.

But is it really possible to build a house or a building using 3D printing? The answer is yes. In fact, the first 3D printed walls were manufactured in 2004, and since then, engineers from all over the world have decided to innovate in this sector.

As for materials, we can say that there is a great variety: from plaster to cement and lime, including mixed or recycled materials.

3D printing and sustainability: minimizing waste in manufacturing

When it comes to any industrial process, one of the biggest challenges is sustainability. 3D printing, besides being an alternative to traditional manufacturing and bringing a lot of advantages, is also positioned as a much more sustainable option and a better way to manage the resources used.

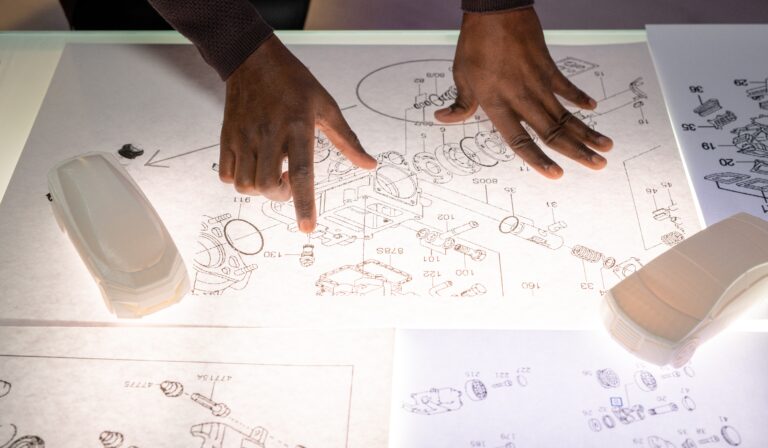

Additive manufacturing makes it possible to produce parts or prototypes, from design through prototyping to manufacturing the final part, in a shorter time compared to traditional methods.

In addition, generating sustainable manufacturing materials is currently one of the challenges facing engineers specializing in this field. However, today there are already materials made from renewable raw materials such as PA11, which is obtained from vegetable castor oil and has a greatly reduced environmental impact.

At ProtoGo! we provide the best service for the development of your parts and prototypes through additive manufacturing. In addition, we specialize in printing using Multi Jet Fusion or MJF, the latest HP technology designed especially for industrial applications.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for?Request your quote now!