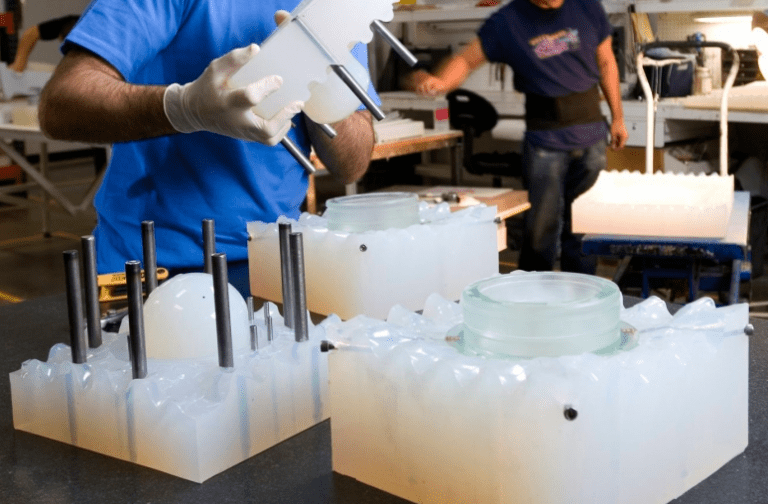

As in any other production process, in silicone molding or vacuum casting, the choice of the right material is an essential factor. When making this decision, it is important to take into account factors such as cost, surface finish, material properties…

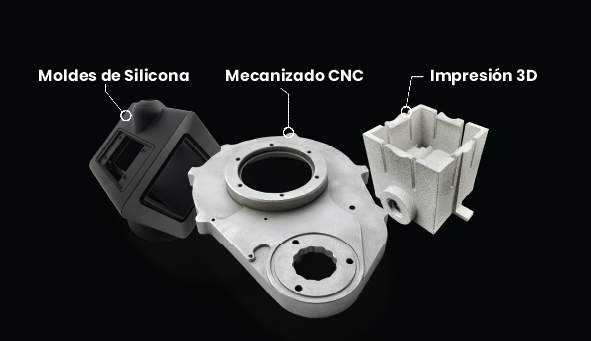

At Proto&Go! we offer you the best materials for the manufacture of your parts and prototypes made by: vacuum casting, CNC machining or 3D printing.

Types of polyurethane for silicone molds

At Proto&Go! we have at your disposal two types of polyurethane and different finishes. In this article we tell you about their characteristics and properties so that you can make the right decision when choosing the material for your project:

First, rigid polyurethane (PUR), a porous material with a closed cell structure. In terms of its characteristics, we can highlight its great power as a thermal insulator, its lightness and its ease of handling. One of its great advantages is that it can be worked with a wide variety of tools: cutter, knife, heat saw, hot wire… On the other hand, it can also be sanded, milled and bonded to other materials with contact glue and special dowels. In addition, it is an organic material and therefore combustible.

Rigid polyurethane can be used in sectors such as aeronautics or industry and also for machine accessories or artificial coatings.

Secondly, we find flexible polyurethane, which is used in numerous industrial processes. It is a mixture of polyol and isocynate, has greater flexibility than other similar agents and is noted for its resistance to the impact of chemical solvents and to tearing.

In terms of applications, it can be used for the industrial sector, for furniture and for technical laboratory equipment, among others.

What types of finishes are available for polyurethane?

At Proto&Go!, in addition to manufacturing your prototypes, we offer finishing for both plastic and metal parts. Thanks to this service, we can provide a complete solution for the construction of your prototypes and the manufacturing of your parts by CNC machining, 3D printing or silicone molds.

We offer a wide variety of finishes such as anodizing, sandblasting, polishing, bluing, zinc plating, chrome plating, nickel plating and painting so that you can choose the type of finish that best suits your needs.

In the case of polyurethane, the finishing possibilities are: transparent, painted or pigmented. For rigid polyurethane, painting provides a surface finish that is applied to different materials to give the part the desired color (either RAL or Pantone). On the other hand, for both rigid and flexible polyurethane, pigmenting is a finish that is applied to the material cast in silicone molds to give mass color to the entire part.

In short, the choice of material is a factor that must be taken into account when manufacturing a part or prototype. It is important to consider which properties or applications best suit the needs of the desired product in order to choose the ideal material.

For more information about the materials available at Proto&Go! we recommend you to visit our materials list.

Request your quotation now and receive your quote within 24 hours!