The industrial sector is constantly evolving, so it is essential for companies to evaluate and adapt to new technologies that improve their productivity and efficiency.

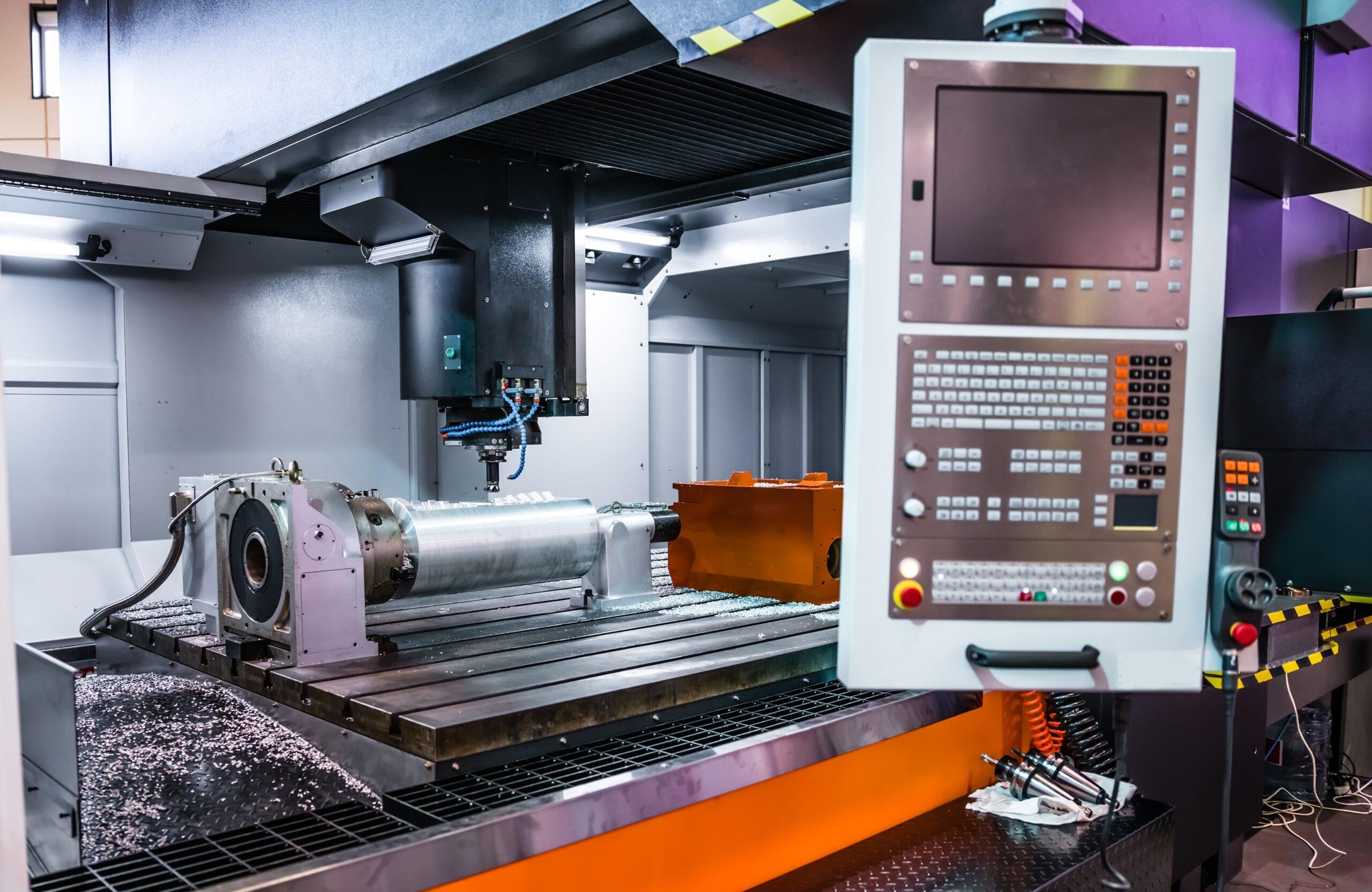

In the context of CNC machining, new techniques have appeared in recent years, including CNC robot systems, which are typically used in the automotive and fast moving consumer goods industries. The main advantage of this innovative technology is the increase in productivity it provides and, therefore, the increase in profits.

On the other hand, its great disadvantage until now was its cost. CNC robots that monitor machines have, until relatively recently, been too expensive, but this factor is changing as more companies are betting on it.

What does machine care consist of?

If we talk about machine tending in the context of CNC machining operations, it usually refers to the process of loading raw material and unloading final parts from a CNC machine.

This process is usually performed by human labor, so it is a costly, time-consuming and even tedious procedure for the workers.

In the case of short production runs, this factor may not make a big difference, but in the case of high volume production, the production cycle time is decisive. Therefore, the time reduction brought about by CNC machine tending robots is a crucial factor in increasing productivity.

Advantages of robotics in CNC machining

More and more companies are turning to CNC robots because of the value they add to their operations and the many advantages they offer. These are some of them:

- Reduction of production cycle times: this is arguably the most important benefit. By using robotics for CNC machine tending, processes can be automated and optimized to minimize the time between loading and unloading operations.

- Manufacturing processes without lighting: another great advantage is being able to turn off the lights in the factory or workshop and production continues smoothly.

- Meeting delivery deadlines: CNC robots can meet delivery deadlines, as their work rhythm is predictable and will not change throughout the production process.

- Maximizing machine utilization: CNC robotics makes it possible to maximize machine utilization and make the machine as efficient and profitable as possible for the company.

What are the applications of CNC robotics for machine tending?

CNC robots also have a wide variety of possible applications:

- Material placement and removal: the raw material can be accurately placed inside the CNC machine and, after machining, the robot will remove the part.

- Tool changes: Although automated tool changers are already integrated into CNC machines, robotic arms can also be used for tool changes and other tasks in turn.

- Part assembly: the CNC tending robot can place machined components directly into the corresponding assembly. This factor reduces assembly time by eliminating the need for human hands in the process.

- Post-processing: if it is necessary to polish the parts after the machining process, this can also be done by a robot, as they offer greater precision and quality in the finish.

- Cleaning: Once the part is removed from the machine, it can be placed in an automatic parts cleaner or dryer to remove any material residue.

In short, the use of robotics for CNC machine tending is an excellent technology to automate and optimize the part manufacturing process. This technology has numerous advantages and applications that can increase a company’s productivity.

In addition, it is important to note that this is an industry that is constantly growing and changing, so it is essential that companies adapt to new technologies and take advantage of all the benefits they offer.

For more information about CNC machining you can visit our website: Proto&Go!

Request your quotation now and receive your quote in less than 24 hours!