CNC machining has been an essential component in industrial manufacturing for decades and its importance has been maintained over time. What’s more, with the advancement of new technologies, new emerging trends in CNC machining of parts and prototypes have developed that are transforming the industry.

In this article we will explore the future and trends in parts machining: How will these trends evolve in 2024? In which direction will CNC machining develop? How will new technologies improve this manufacturing process?

The Industry 4.0 revolution and CNC machining

The fourth industrial revolution is having a major impact, not only socially, but also on the industrial sector and manufacturing processes. For companies, it is essential to adapt to these changes, modernize and take advantage of the business opportunities they enable. In addition to taking into account the needs of consumers and offering them what they ask for, optimizing products and increasing competitiveness.

Automation in the CNC machining process is paving the way to new, more productive markets, and arguably the most important trend in the CNC machining industry. These automated machines can operate without human intervention, which reduces labor costs, increases efficiency and improves accuracy and product quality.

Artificial Intelligence is another emerging trend in the CNC machining industry, which can be used to optimize CNC machine programming and, therefore, to improve production efficiency and accuracy. In addition, it is very useful for predicting machine problems before they occur, which can reduce downtime and minimize unnecessary costs.

How does sustainability work in machining?

Another issue that is making a huge change in the industry is sustainability. By combining new technologies in metal recycling and new strategies in machining, it is possible to obtain machining capable of achieving maximum productivity and performance, as well as extended tool life and minimum energy consumption.

On the other hand, when tools or machinery have reached the end of their useful life, despite this extension, the raw material can be reused thanks to today’s advanced and innovative recycling processes.

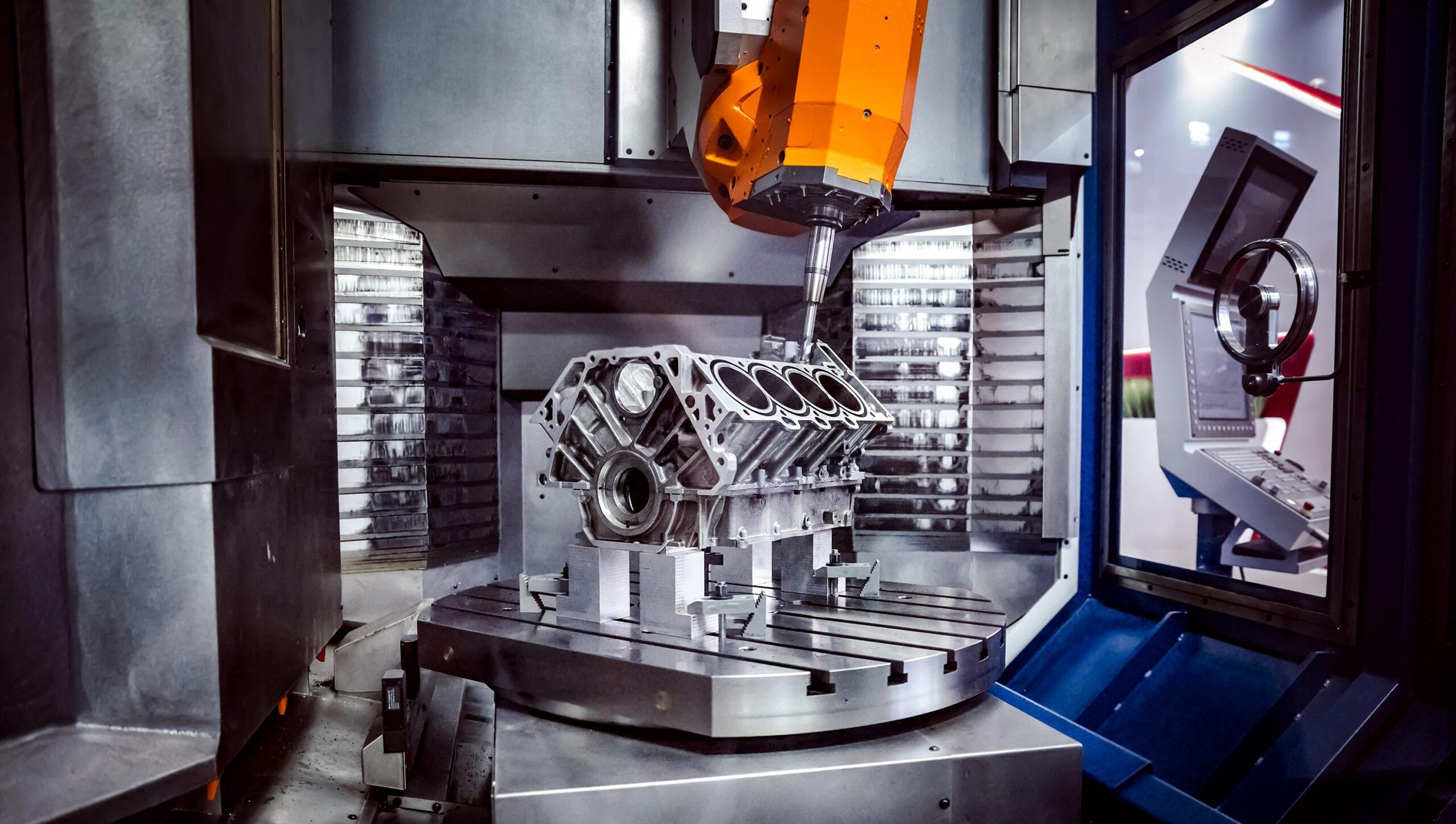

Advances in machining: use of robotics for the care of CNC machines

In the context of CNC machining operations, machine tending refers to the process of loading the raw material and unloading the final parts. These actions are normally performed by human labor, which means that the employee must be present during the entire process. This factor is time consuming and can be tedious and expensive.

When a company is faced with high volume production, cycle time becomes an essential factor. Any delays or incidents are magnified by the need to start and stop production. This is minimized with the use of robotics, since, unlike human labor, robots do not require shift changes or breaks during the production cycle. This is why robots that supervise CNC machines are highly effective in improving productivity and profitability in the production process.

At Proto&Go! we aim to offer you the highest precision and quality CNC machined parts for your projects.

What are you waiting for? Request your quotation now and receive your quote in less than 24 hours!