When we talk about CNC machining, the first material that comes to mind is aluminum. This is the most common, as few materials have the same versatility, flexibility and strength-to-weight ratio.

In addition, aluminium is a material that can be machined much faster than more traditional materials such as titanium or steel. Add to this the speed, the advantages it offers and its elegant finish, and this material can be used in devices such as smartphones and structural supports.

What are the main aluminium CNC machining processes?

CNC machining is a process by which the manufacturer uses computer-controlled machines to machine aluminium parts with a high level of precision, consistency, productivity and design freedom. It also takes into account the importance of generating as little waste as possible to make it a sustainable process.

These are the most common CNC machining processes:

- CNC cutting: This is the process of cutting a piece of aluminium using tools such as blades, cutting wires or, alternatively, saws.

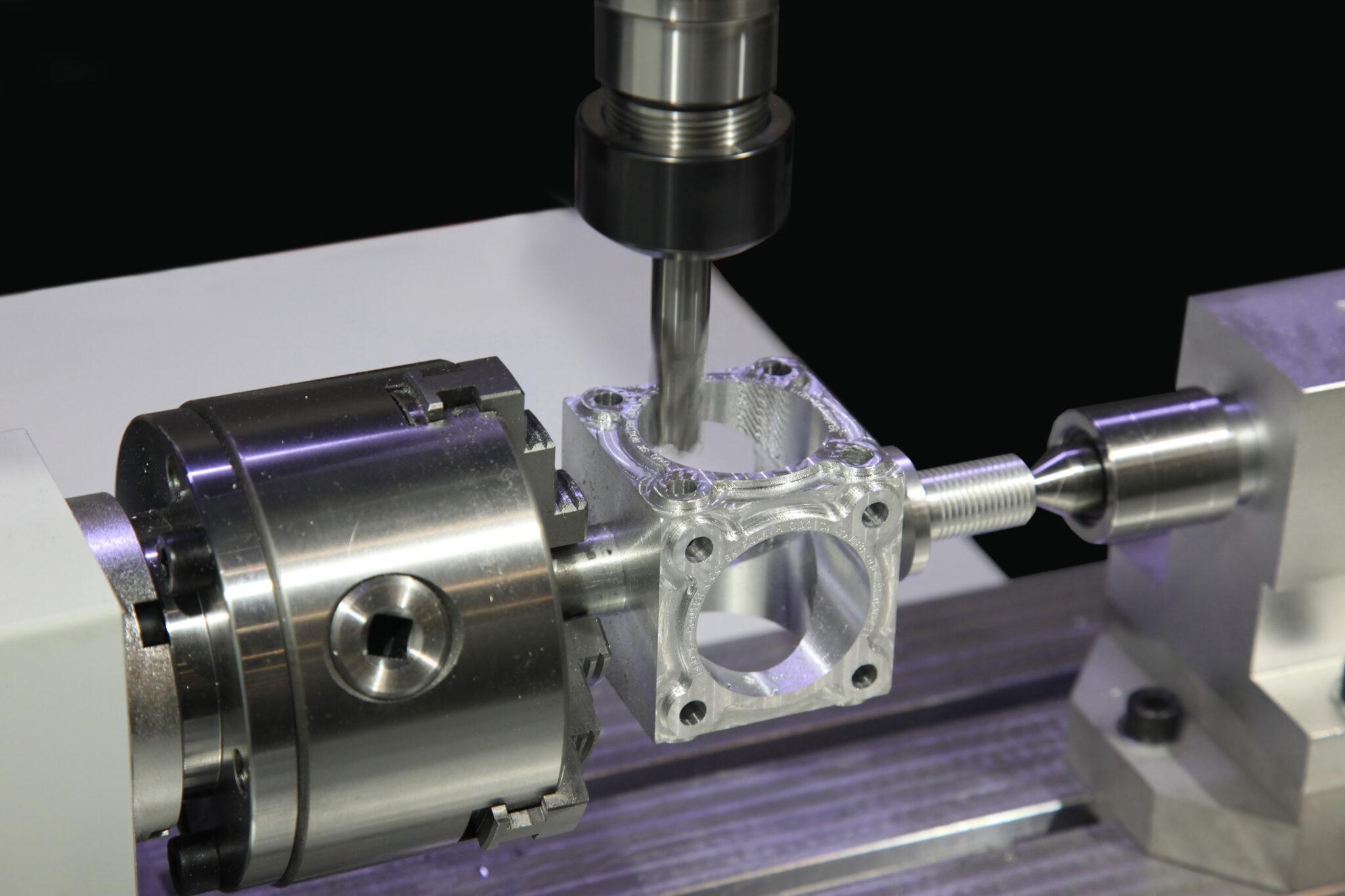

- CNC milling: this is one of the most common, the excess material is removed from the part with the use of a rotating tool called a milling cutter. These can be of different sizes and shapes and are mainly used for machining different designs and shapes on aluminium parts.

- CNC threading: this process creates threads on aluminum parts using a tool called a spindle. These threads can be used to join aluminum parts together or other materials.

- CNC drilling: with this process we can create precise holes in aluminium parts.

All these processes achieve parts with high levels of precision, and thanks to CNC machining, we can produce a high number of parts with the same characteristics and exact dimensions.

What are the applications of CNC machining of aluminium?

Aluminium is often used in the manufacture of precision parts which must have high tolerances and reproducibility, and which must meet very tight tolerances in sectors such as aeronautics. Aluminium is a material capable of withstanding high temperatures, heavy loads and weight.

Parts manufactured by CNC machining are also used in sectors such as automotive, electronics, or construction. These parts may be part of the body of a vehicle, may be a component of the brakes, a heat sink or may be part of doors, windows and supporting structures.

At Proto&Go! we offer the ideal services to satisfy most of the needs that our customers have when developing the parts of a product. We reduce turnaround times and offer a high quality service to ensure that all the parts we manufacture meet the requirements of the designs demanded.

Request your quotation on our website and receive your quote in less than 24 hours!