Although CNC milling .has been around for more than 50 years, technology has advanced significantly, allowing complete automation of the process from design to finished part.

These advances have made this technology available to everyone, facilitating both large runs and small productions, from prototyping to final parts, with really short lead times.

In this article, we tell you what modern CNC milling is, its fundamental principles and how the latest innovations can further optimize this crucial process for manufacturing parts and prototypes with high quality and precision.

How does CNC milling work?

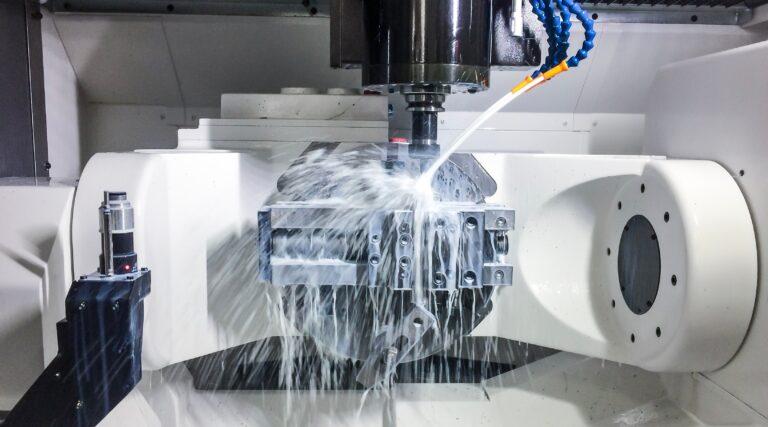

CNC milling is a machining process that uses rotary cutting tools to remove material from a workpiece, creating three-dimensional shapes with high precision and accuracy.

This production process is commonly used in the .manufacture of complex parts for a variety of industries, including the automotive, aerospace, medical and general industrial sectors.

It is a process that combines advanced computer technology with precision machinery to cut and form detailed parts. The process begins with the creation of a 3D model of the part in CAD software, which is then converted into G-code by CAM software, which defines the tool paths and cutting parameters.

Once designed and programmed, the machine is configured. The workpiece is clamped on the CNC machine table and the cutting tool is mounted on the spindle. It is imperative that the machine is calibrated to ensure accurate movements and correct part alignment.

During the milling process, the cutting tool moves along the X, Y and Z axes, and even additional axes, following programmed paths. The tool rotates at a high speed and manages to remove material from the workpiece, creating the desired shape with great precision.

Improvements in CNC milling

Although there are several types of CNC milling machines, the most common are the 3-axis ones, that is, those that move along the X, Y and Z axes and allow manufacturing in 3 dimensions.

The 5-axis CNC machines have greatly improved this process by adding two more directional movements. It is an ideal technology for the manufacture of complex parts and prototypes that require higher precision.

The immediate future of CNC machining

In recent years, much has evolved, both in the design and development of parts by CNC machining, as well as in the development of CNC milling machines.

In terms of machinery, we can find CNC milling machines that are increasingly more complex, larger and more complicated to operate, i.e. they require more experience or skills.

In short, we can say that in the future we can expect even more improvements in the CNC milling process and, therefore, also improvements in the quality and precision of the parts manufactured using this technology.

At ProtoGo! we offer the best CNC machining service for your parts and prototypes. You can request your quotation through the form on our website in a quick and easy way.

What are you wating for? Request your quote now!