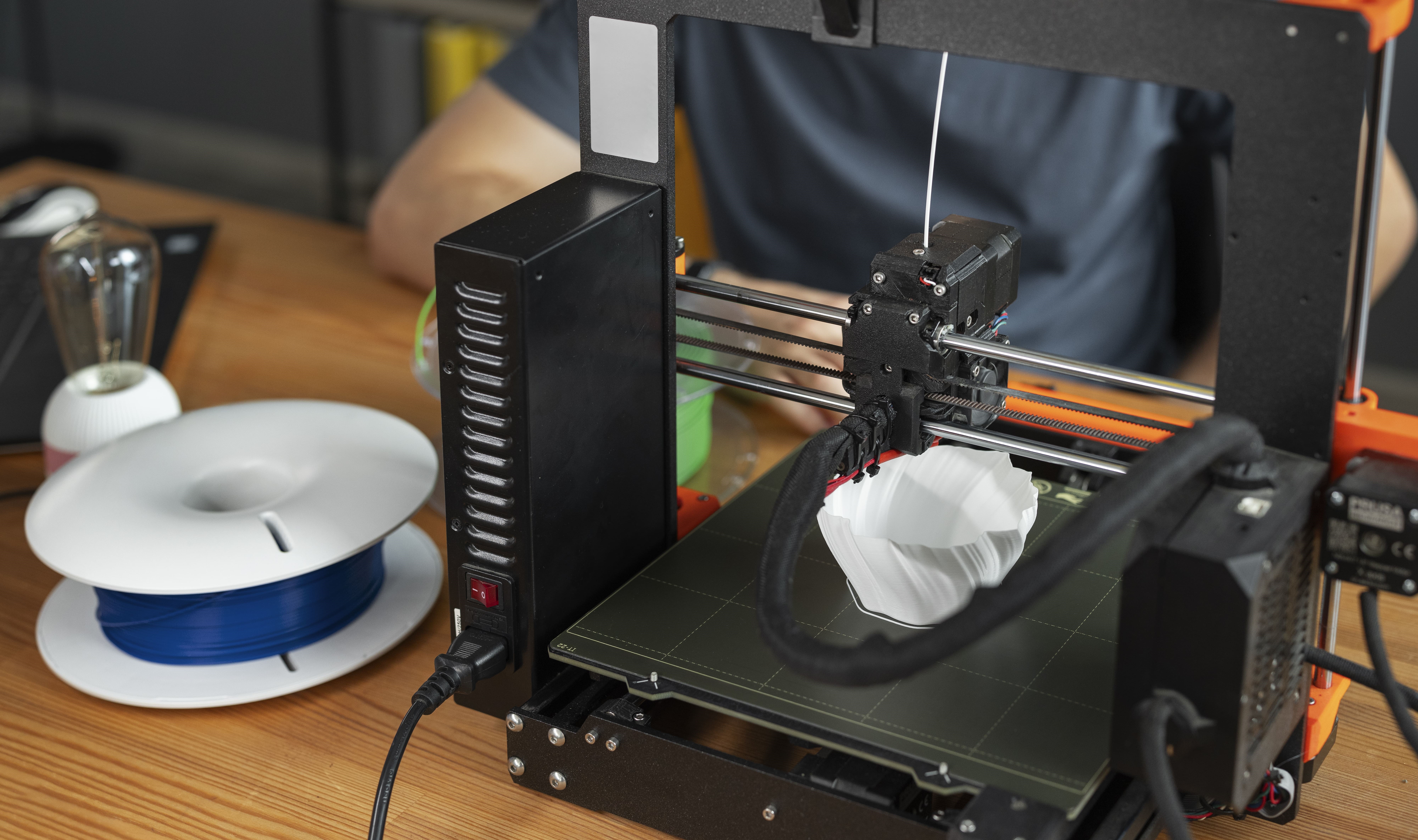

3D post-processing is a crucial step in additive manufacturing that is often overlooked, but can make the difference between a functional part and a finished masterpiece.

Although stampa 3D abbia rivoluzionato il modo di progettare e produrre oggetti, il processo non termina quando la stampante si ferma. Dalla rimozione del supporto alla levigatura, lucidatura e verniciatura, la post-elaborazione è ciò che dà vita alle parti stampate, migliorandone l’aspetto, la funzionalità e la durata.

In this article, we’ll explore everything you need to know about 3D post-processing, from the most common techniques to the materials that benefit from these treatments, so you can take your creations to the next level.

How to fix flaws in your 3D printed part?

After 3D printing a part, it is common to encounter imperfections such as rough surfaces or support marks. Removing these imperfections is essential for a clean, professional finish. The most common techniques for correcting imperfections include:

- Sanding: To smooth surfaces and remove visible coating lines. Usually start with coarse grit sandpaper and progress to finer grits.

- Polishing: Polishing after sanding provides a shinier and smoother finish, especially on plastic parts such as ABS and PLA.

- Acetone for ABS: A treatment with acetone vapors can automatically smooth ABS parts, giving them a smooth and shiny appearance.

In addition, there are specific post-processing tools that allow retouching, repairing, correcting burrs, filing corners…

Gap filling in 3D prints

In some cases, it is necessary to fill small imperfections before painting or applying any other finish coat. Void filling is a very useful technique for repairing small cracks or holes in 3D printed parts..

Para hacerlo, se pueden emplear varias herramientas y materiales, como:

- Modeling putty or epoxy: The putty is ideal for covering small areas or joints in large parts. Once applied and hardened, it can be sanded to a smooth finish.

- Adhesives or resins: In case of multi-part prints, specific adhesives for plastics or epoxy resins can help to fill gaps or joints between parts, offering greater resistance.

- Liquid plastics or filament welding: Some use molten filament with tools such as a 3D welder to fill gaps, ensuring that the material is the same as the printed part.

After applying any filler material, it is advisable to sand again to level the surface and prepare the part for subsequent steps, such as painting or coating.

Is it possible to automate 3D post-processing?

In recent years, there has been significant progress in the automation of 3D post-processing. Although these processes are usually quite manual, there are industrial systems that can perform tasks such as sanding, polishing and even coating application automatically.

In any case, it is important to note that these automation systems are ideal for mass production, in domestic or small-scale environments, but manual post-processing is still the most accessible option. However, it is likely that in the coming years we will see more advances that will make 3D post-processing fully automated and accessible to all types of users.

At ProtoandGo! we provide the best service for the development of your parts and prototypes through additive manufacturing. In addition, we specialize in printing using Multi Jet Fusion or MJF, the latest HP technology designed especially for industrial applications.

Through our online platform you can request a quotation for your parts and our team will give you an answer in less than 24 hours.

What are you wating for? Request your quote now!