Machined parts have become indispensable in modern engineering. They are produced under complex precision levels and very detailed processes to achieve the perfect result. How do we do it at Proto&Go!? We tell you about it in this post.

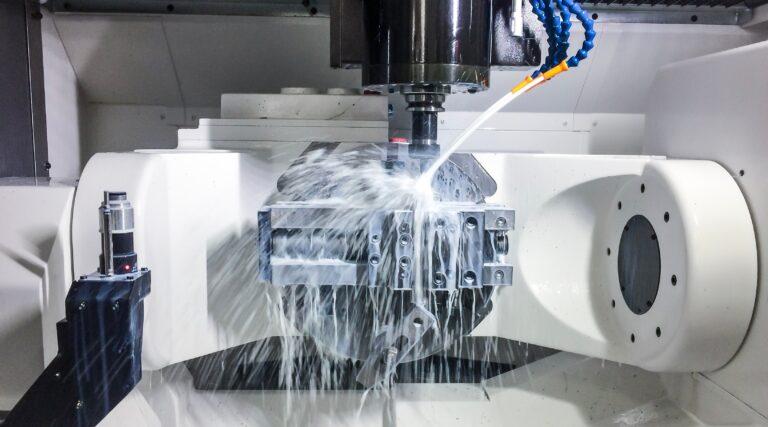

In our machining workshop we have state-of-the-art 5-axis machines with which we manufacture parts. Our machines are capable of cutting on five different axes, allowing us to create highly complex and precise parts.

The machining of parts with 5-axis machines is particularly useful in the manufacture of parts with complex shapes, such as turbines, aeronautical components, moulds and dies, among others. Thanks to the ability of these machines to work in multiple angles and positions, at Proto&Go! we can create parts with curved shapes and precise contours, making them ideal for use in a variety of industries.

Machined parts, what are they?

To understand the manufacturing process of machined parts, it is important to understand what CNC machining is and how these items are produced. When we talk about machined parts, we are referring to all those parts that have been manufactured using the machining technique. This is a process by which very precise and almost perfect parts can be achieved. How? Thanks to its geometry, size and perfect finishes it meets the manufacturing needs required. They are simply detail-produced elements that fulfil a very specific function within a system.

While many people are curious about how CNC machining works, it is often assumed that CNC machining is only used to develop metal parts. However, this process can also be carried out with other materials such as plastic. Find out what materials you can use for your pieces at Proto&GO!

What techniques are applied in machining processes?

Do you know how a machined part fits into a system or infrastructure? There are different techniques used for the detachment of the material. Each of them has a different cut and, therefore, the classification of this piece will also be different. A very important part of the manufacture of machined parts is the tools that are used and the technique that is used.

In our CNC machining workshop, we produce the parts from a mass of material from which the excess is removed with a tool until the desired shape is achieved. This is a cutting process that produces waste material known as swarf, which is why this technique is known as swarf removal machining.

Now that you know how our machining workshop works and how we manufacture parts, what are you waiting for to find out more about our services?

The machining of parts at Proto&GO!

One of the main advantages of working with 5-axis machines is that workpieces can be machined faster and more accurately than with machines with fewer axes. In addition, by using CAD software, simulations can be carried out prior to actual machining, allowing problems to be detected and solved before manufacturing begins. The result of the machining process is a part that meets the specifications for which it was designed and planned.

In short, our 5-axis machine shop allows us to use advanced manufacturing techniques to produce complex parts with exceptional precision. These machines are a costly investment, but are essential in the production of advanced components for various industries requiring high precision parts.

Upload your plans to our website, select the material and request your quote. Nosotros nos encargamos de que recibas tus piezas perfectas, gracias a nuestro departamento de control de calidad.

What are you wating for? Get in touch now!